Wringing machine with flow guide mechanism

A technology of diversion mechanism and water squeezer, which is applied in raw hide/leather/fur manufacturing equipment, small raw hide/large raw hide/leather/fur mechanical treatment, small raw hide/large raw hide/leather/fur treatment, etc., which can solve the inconvenience Manage and manufacture complex structures, inconvenient large-scale production and manufacturing, etc., to achieve the effect of easy management and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

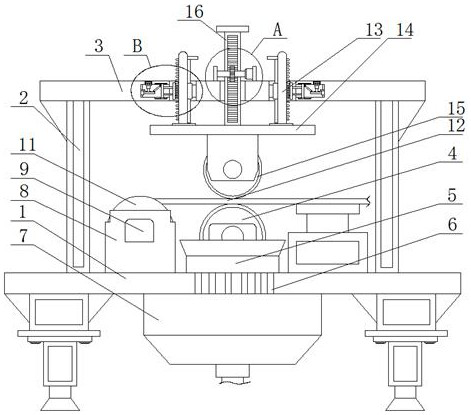

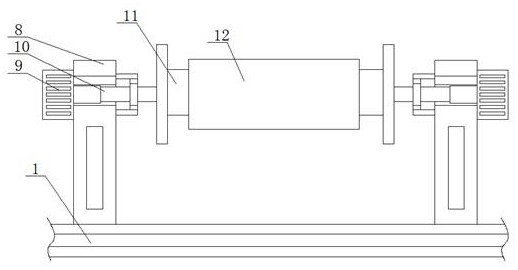

[0026] refer to Figure 1-5 , a water squeezing machine with a diversion mechanism, including a fixed frame 1, two symmetrically arranged support plates 2 are fixedly installed on the top of the fixed frame 1, and the same top plate 3 is fixedly installed on the top of the two support plates 2, The top of the fixed frame 1 is fixedly equipped with a flow guide tube 5, and the top of the fixed frame 1 is fixedly equipped with a lower drum 4, and the lower drum 4 is located in the flow guide tube 5, and the fixed frame 1 is provided with a plurality of flow guide holes 6. Each diversion hole 6 is positioned directly below the diversion pipe 5, and the bottom of the fixed frame 1 is fixedly equipped with a water tank 7, and a plurality of diversion holes 6 are all connected with the water tank 7, and the top of the fixed frame 1 is fixedly installed. There are two mounting bases 8 arranged symmetrically, and the same storage roller 11 is rotatably connected to the two mounting ba...

Embodiment 2

[0035] refer to Figure 1-5 , a water squeezing machine with a diversion mechanism, including a fixed frame 1, two symmetrically arranged support plates 2 are fixedly installed on the top of the fixed frame 1, and the same top plate 3 is fixedly installed on the top of the two support plates 2, The top of the fixed frame 1 is fixedly equipped with a flow guide tube 5, and the top of the fixed frame 1 is fixedly equipped with a lower drum 4, and the lower drum 4 is located in the flow guide tube 5, and the fixed frame 1 is provided with a plurality of flow guide holes 6. Each diversion hole 6 is positioned directly below the diversion pipe 5, and the bottom of the fixed frame 1 is fixedly equipped with a water tank 7, and a plurality of diversion holes 6 are all connected with the water tank 7, and the top of the fixed frame 1 is fixedly installed. There are two mounting bases 8 arranged symmetrically, and the same storage roller 11 is rotatably connected to the two mounting ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com