Beating and shaping die of annular pipe fitting

A technology for annular pipe fittings and forming molds, which can be used in forming tools, manufacturing tools, metal processing equipment, etc., and can solve problems such as bending at both ends

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

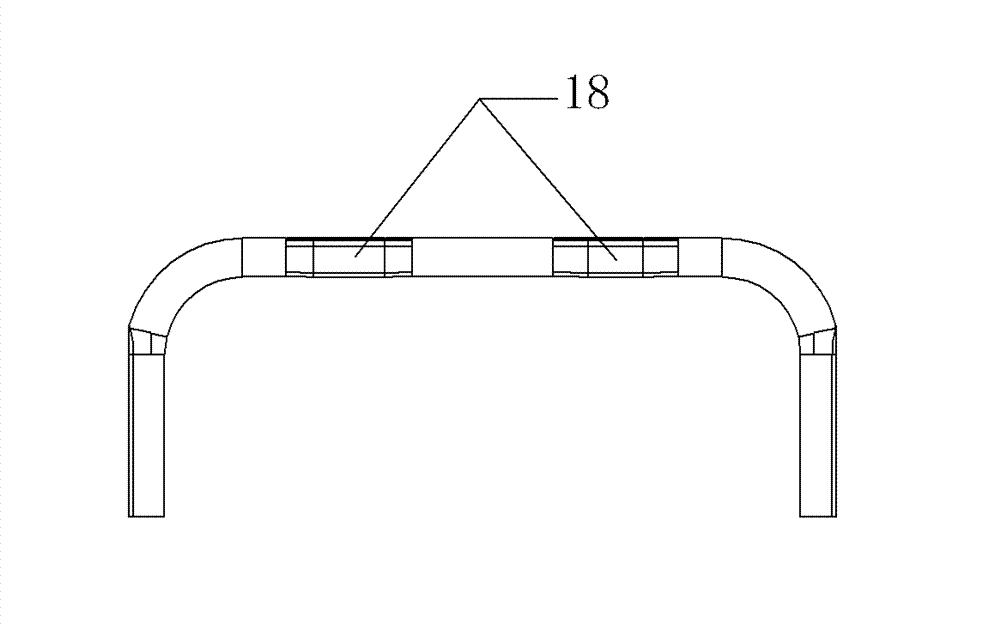

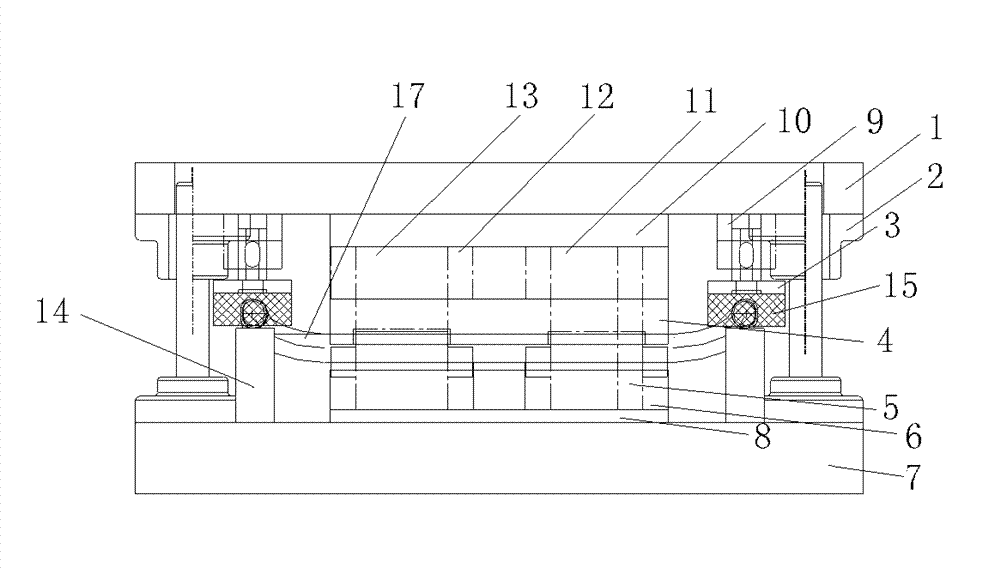

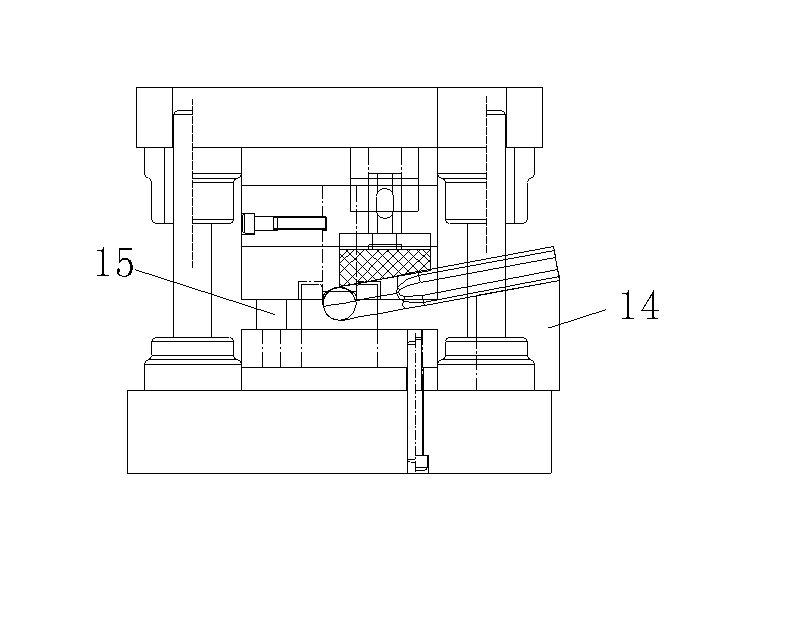

[0013] See figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 , the mold of the present invention includes an upper mold structure and a lower mold structure, the upper mold structure includes an upper template 1, an upper backing plate 10 is installed on the lower part of the upper template 1, an upper fixing plate 12 is installed on the lower part of the upper backing plate 10, and the upper fixing plate 12 Flat punches 11, 13 are installed, and upper binder plate 4 is installed under the upper fixed plate 12. The lower mold structure includes a lower template 7, and a lower fixed plate 6 is installed on the lower template 7, and a molding concave is installed on the lower fixed plate 6. The mold 5 also includes a pressing device, which is installed on the upper template 1 . There are two compression devices, and the two compression devices are located above the curved section of the annular pipe fitting 17; the compression device includes a compactor 3, which is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com