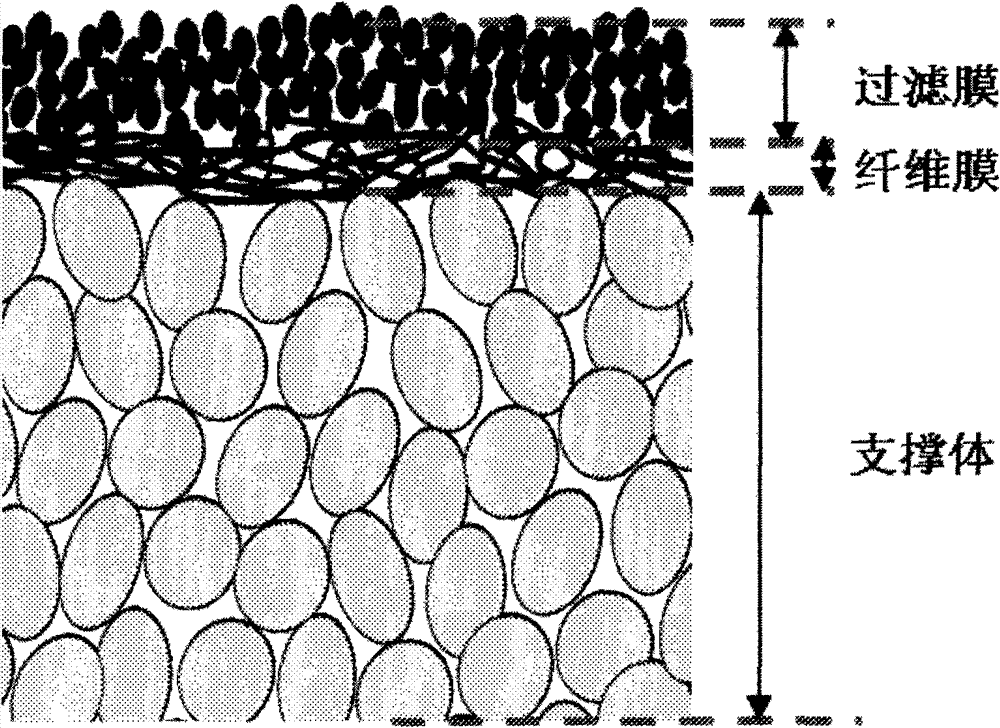

Double-layer asymmetrical surface film of porous ceramic filter tube for dust filter and preparation method thereof

A porous ceramic and dust filtration technology, applied in membrane technology, semi-permeable membrane separation, chemical instruments and methods, etc., can solve the problems of reducing the thickness of the surface membrane, reducing the filtration pressure drop, etc., to improve performance, reduce filtration pressure drop, Reasonable effect of structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

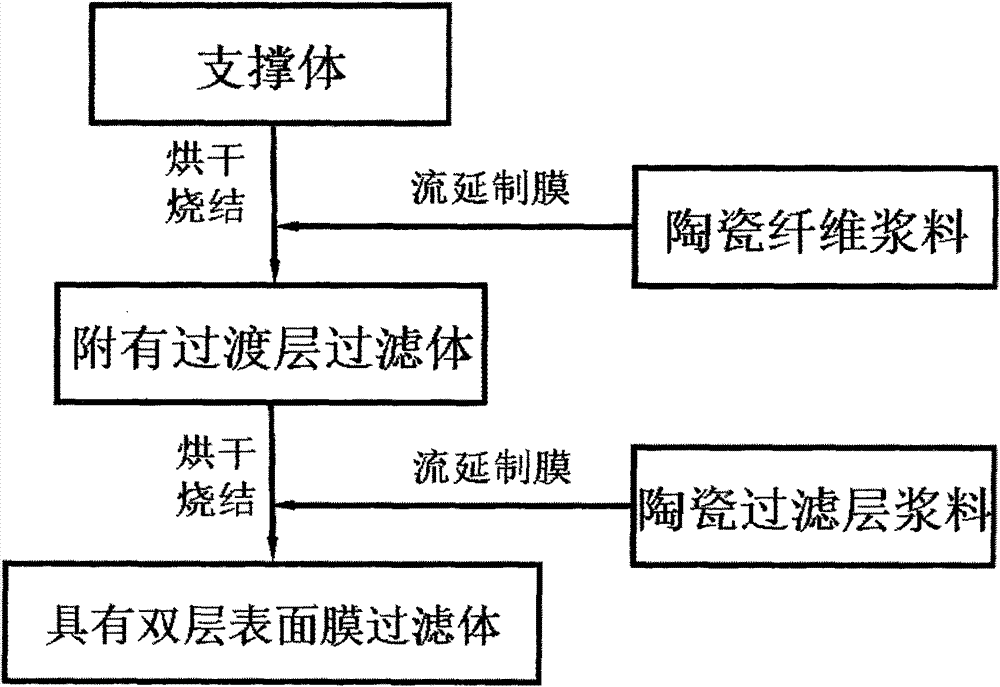

[0031] (1) First prepare the ceramic fiber slurry; add the ceramic fiber and the dispersant to a certain solvent, heat the solvent and keep stirring the mixed solution until the ceramic fiber is evenly dispersed;

[0032] (2) The ceramic fiber slurry with good dispersibility prepared in step 1 is coated on the porous ceramic support by a suitable film-making method to form a ceramic fiber blank film with a complete surface and uniform film thickness of a certain thickness, and It is dried at a certain temperature;

[0033] (3) Prepare the slurry of the filter membrane; select ceramic powder and binder with a specific average particle size, disperse it in a specific solvent, and finally form a filter membrane slurry with well-dispersed solid particles and suitable viscosity;

[0034] (4) The slurry prepared in step 3 is formed on the ceramic fiber blank membrane with a suitable thickness and good integrity of the filter membrane blank membrane by a suitable membrane-making meth...

Embodiment 1

[0047] First, add 2g of mullite fiber with a diameter distribution of 1μm to 500μm and an aspect ratio greater than 10 and 1.5g of sodium carboxymethylcellulose into a beaker, then add a sufficient amount of water, heat to boil and stir at the same time until the mullite The fibers are uniformly dispersed and the mullite fiber mass fraction reaches 5%, and the fiber film slurry is obtained. In addition, 9 g of silicon carbide powder with a particle size of 54 μm and 1 g of kaolin were magnetically stirred and mixed in 35 ml of deionized water to obtain filter membrane slurry.

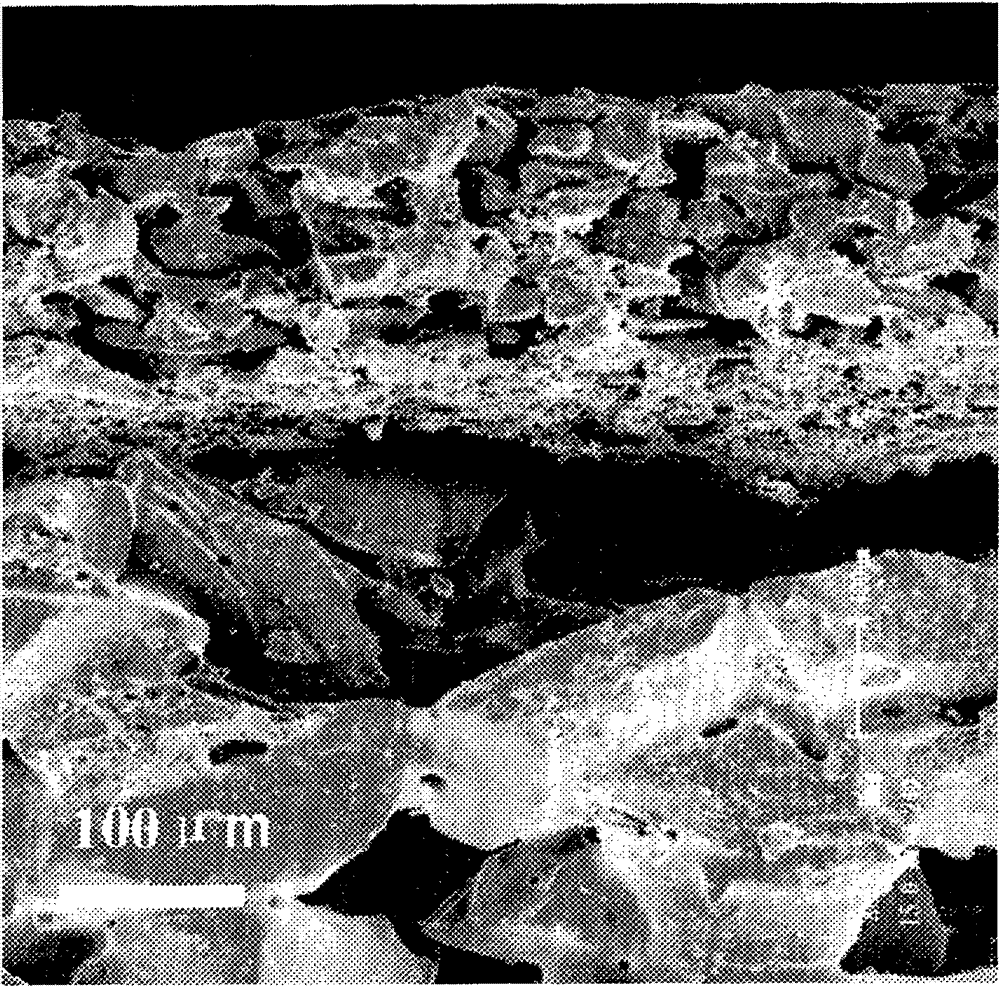

[0048] The obtained mullite fiber slurry was cast on a silicon carbide support sheet to prepare a fiber blank film, and the fiber blank film was dried at 110°C. Then, a filter membrane is prepared on the mullite fiber blank membrane by casting method, which is also dried at 110°C. Finally, the porous ceramic with double-layer asymmetric surface membrane was sintered at 1280°C for 3h.

[0049] The prep...

Embodiment 2

[0052] First, add 1g of mullite fibers with a diameter distribution of 1 μm to 500 μm and an aspect ratio greater than 10, 1 g of aluminum silicate fibers with a diameter distribution of 1 μm to 500 μm and an aspect ratio greater than 10, and 2 g of polyvinyl alcohol into a beaker, and then add A sufficient amount of water is heated and boiled while stirring until the mullite fibers are uniformly dispersed and the mass fraction of the mullite fibers reaches 10%, to obtain a fiber film slurry. In addition, 9 g of mullite powder with a particle size of 20 μm and 1 g of kaolin were magnetically stirred and mixed in 35 ml of deionized water to obtain filter membrane slurry.

[0053] The prepared mixed slurry of mullite fiber and aluminum silicate fiber was cast on a silicon carbide support sheet to prepare a fiber blank film, and the fiber blank film was dried at 110°C. Then, a filter membrane is prepared on the mullite fiber blank membrane by casting method, which is also dried a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com