Powder coating material and fluorine-containing laminate

A technology of powder coatings and laminates, applied in the direction of powder coatings, coatings, polyamide coatings, etc., to achieve the effect of improving the adhesion of substrates, increasing the contact area, and preventing oxidation and deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

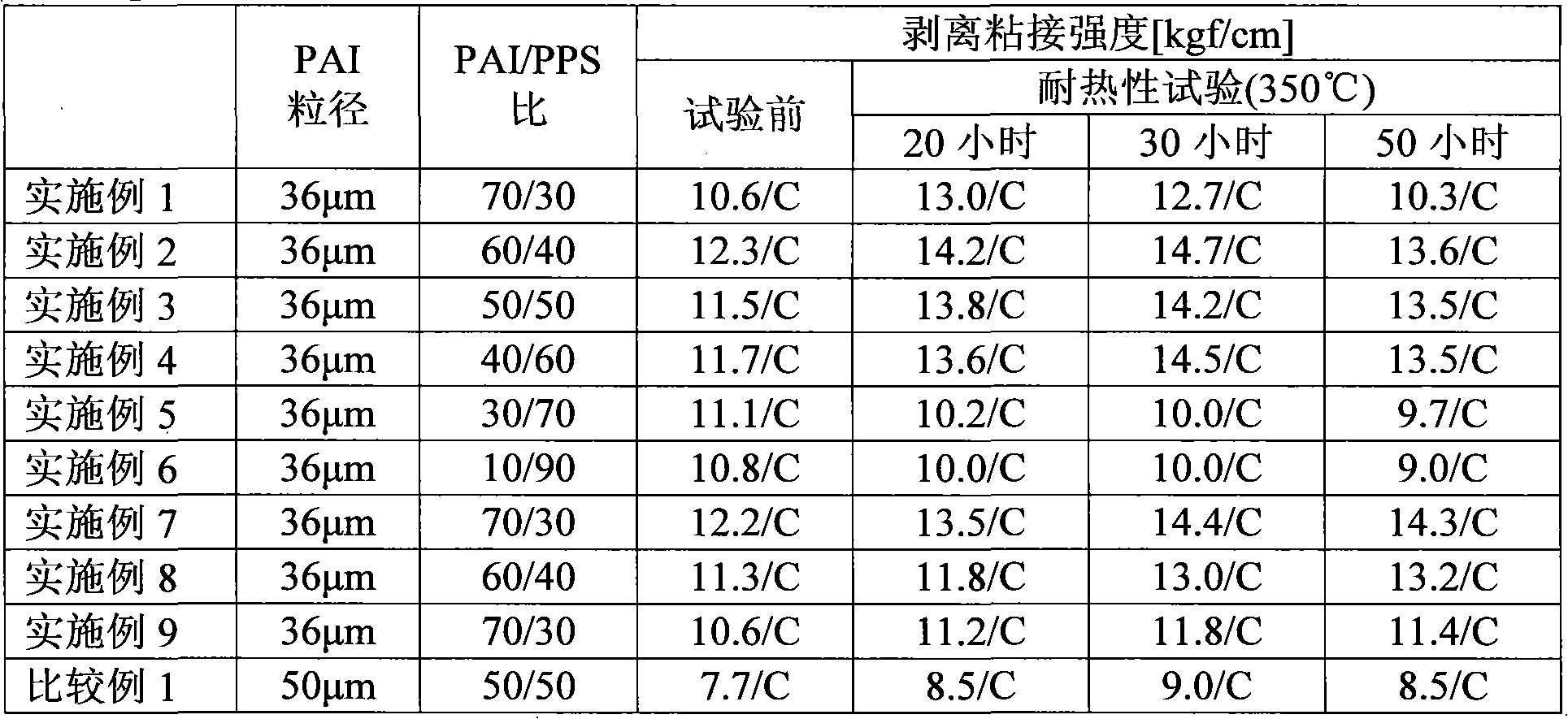

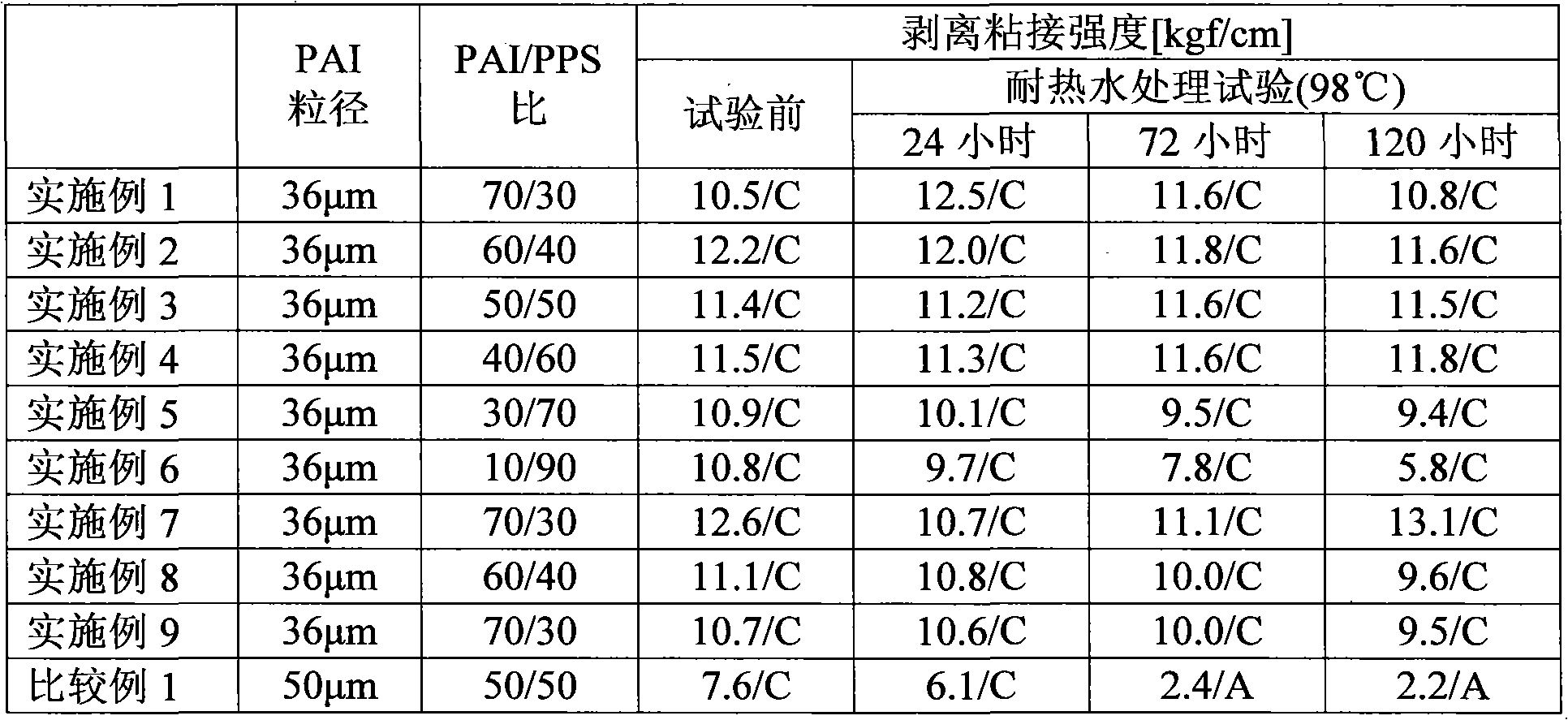

Embodiment 1

[0120] Polyamide-imide resin (trade name: Tolone 4000T-40, manufactured by Solbeard Bansto Polymers Co., Ltd.) [PAI] was pulverized using a pulverizer (trade name: Atomayzer, manufactured by Dalton Corporation) to obtain an average A pulverized product of PAI particles with a particle size of 36 μm. 70 g of the obtained PAI particle pulverized product, 400 g of tetrafluoroethylene / perfluoro(alkyl vinyl) ether copolymer [PFA] (melting point: 310° C., average particle diameter: 25 μm), 30 g of polyphenylene sulfide resin [PPS ] (trade name: Laiton V-1, manufactured by Phillips Corporation, average particle size: 17 μm) was uniformly dispersed by a mixer (trade name: V-type Brenda, manufactured by Dalton Corporation) to obtain the powder coating of the present invention.

[0121] An iron plate (SS400, length 100 mm × width 50 mm × thickness 1.5 mm, average roughness degree [Ra] = 2 to 3 μm), the above-mentioned powder coating is electrostatically applied to a film thickness of 1...

Embodiment 2

[0133] Except having changed the quantity of PAI into 60g, and the quantity of PPS into 40g, the laminated body B was produced by the method similar to Example 1, and the evaluation similar to Example 1 was performed.

Embodiment 3

[0135] Except having changed the quantity of PAI into 50g, and the quantity of PPS into 50g, the laminated body C was produced by the method similar to Example 1, and the evaluation similar to Example 1 was performed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| coating thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com