Resonant cavity capable of obtaining hollow laser beams

A hollow laser beam and resonant cavity technology, applied in the field of resonant cavity, can solve the problems of reduced laser beam coherence, complex structure, large energy loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

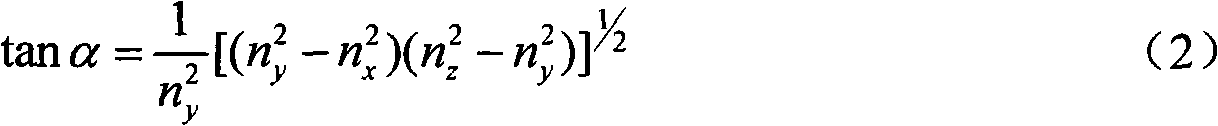

[0025] The resonator that can obtain the hollow laser beam of the present invention is made up of mirror 1, laser gain medium 2 and output coupling mirror 3, see figure 2 As shown, the material of the output coupling mirror 3 is a biaxial crystal, and one optical axis of the biaxial crystal is parallel to the axis of the resonant cavity. The pumping source 4 is an 808nm 30W laser diode array. The pump light 4 is coupled into the laser gain medium 2 in the resonant cavity by a coupling device. The coupling device is composed of a coupling fiber 5 and a coupling lens 6 . The coupling fiber 5 has a core diameter of 400 μm and a numerical aperture NA=0.22. The coupling lens 6 is composed of a pair of plano-convex lenses with opposite convex surfaces and a convex radius of 50mm. Both sides of each plano-convex lens are coated with an 808nm anti-reflection film, and the transmittance T>95%. Reflector 1 is a plano-concave mirror, one side of the cavity is concave, both sides are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com