Insulator

A technology of insulators and flanges, applied in the direction of insulators, lead-in/through-type insulators, electrical components, etc., can solve the problems of poor sealing performance, inconvenience, easy leakage and installation, etc., to achieve good mechanical properties, firm combination, The effect of avoiding weld cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

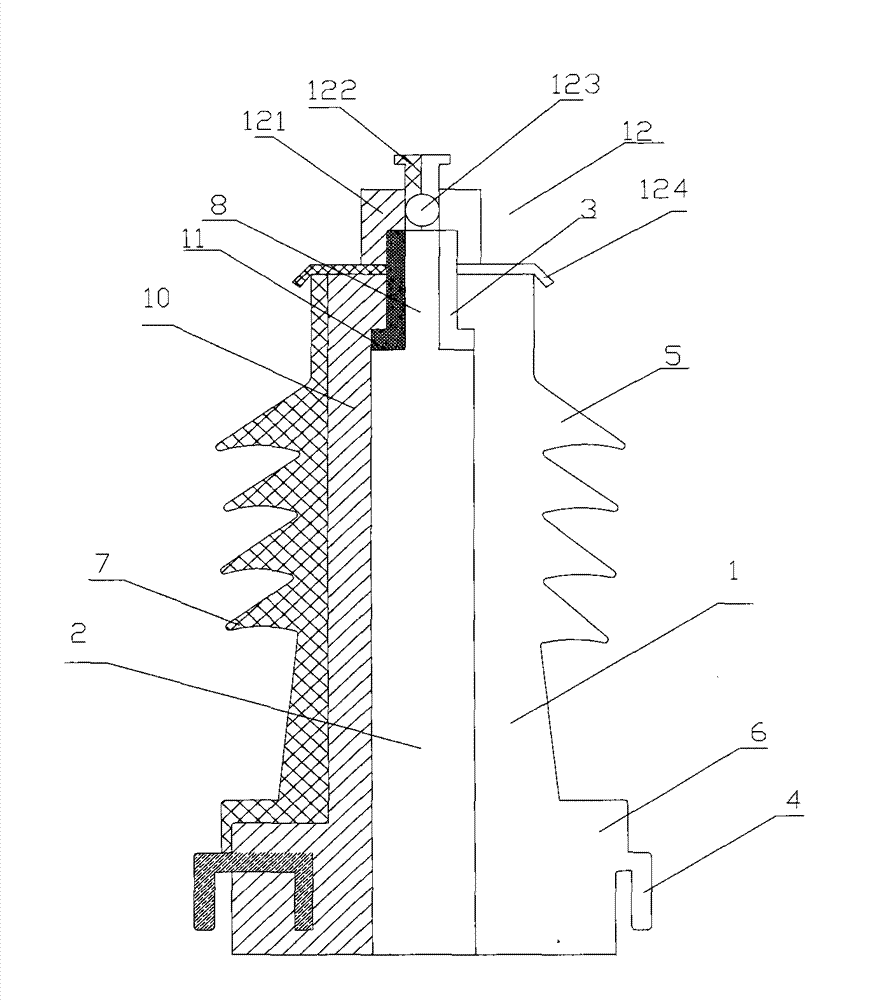

[0035] See figure 1. The insulator in this embodiment includes an insulator body 1, the insulator body 1 is composed of a resin inner core 10 with a central axis hole 2 and a rubber layer 7 wrapped outside the resin inner core 10; The outer wall is provided with a plurality of rubber sheds 5, where the rubber layer 7 and the sheds 5 are integrally formed; the upper inner wall of the resin core 10 is provided with an inwardly protruding ring-shaped blocking boss 11. A metal terminal 3 is cast on the upper end of the resin core 10. Here, the metal terminal 3 is a cylinder, and the metal terminal 3 has a through hole 8 along its central axis. The metal The upper end of the terminal post 3 protrudes from the upper end surface of the resin core 10 and passes through a through hole of a metal cap 124, and is fixed with a wiring fixture 12, and the lower end surface of the wiring fixture 12 is connected to the metal cap 124. The upper end surface of the wire is pasted together. Her...

Embodiment 2

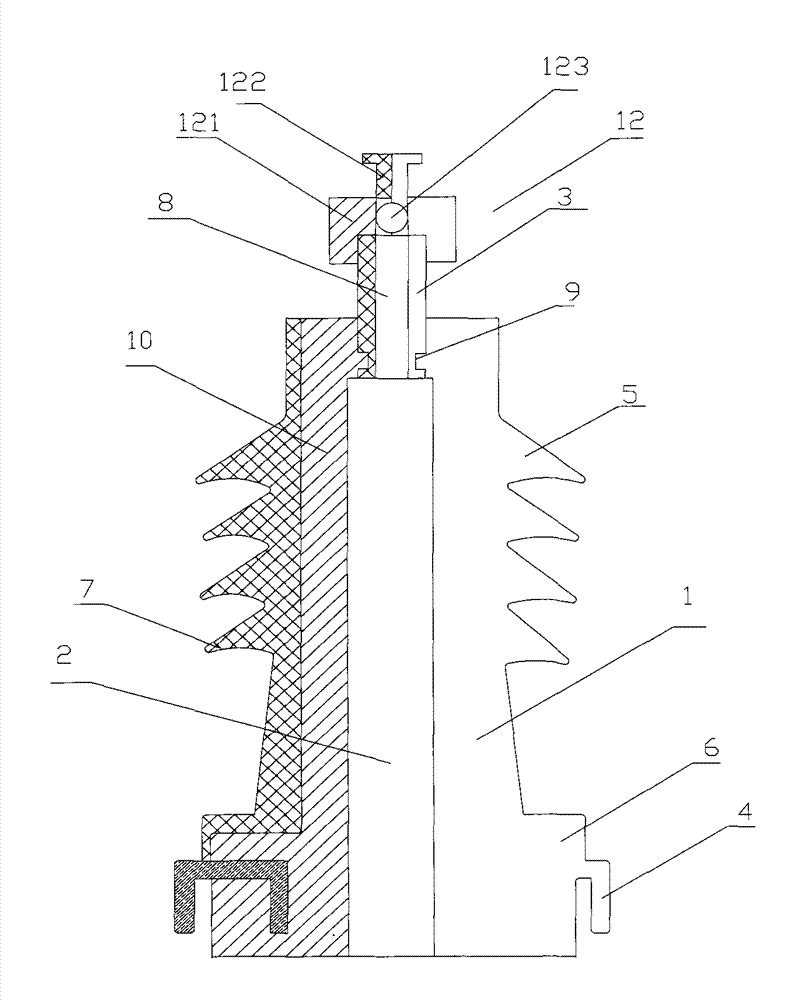

[0037] See figure 2 . The insulator in this embodiment includes an insulator body 1, the insulator body 1 is composed of a resin inner core 10 with a central axis hole 2 and a rubber layer 7 wrapped outside the resin inner core 10; A plurality of rubber sheds 5 are arranged on the outer wall, and the rubber layer 7 is integrally formed with the sheds 5; the metal terminal 3 is a cylinder here, and the metal terminal 3 is formed along its own The central axis has a through hole 8, the upper end of the metal terminal 3 protrudes from the upper end surface of the resin core 10, and is fixed with a wiring fixture 12. Here, the wiring fixture includes a metal wiring The columnar wiring support seat 121 on the column 12, the columnar wiring support seat 121 is provided with a wiring through hole 123 in the horizontal direction, and is respectively provided with a through hole with internal thread in the vertical and vertical directions, and a fastening screw 122 passes through the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com