Spectral standardization-based coal quality on-line detection method

A detection method and spectral technology, which is applied in the field of coal quality detection, can solve problems such as insufficient precision, inability to realize full element analysis, and large investment, and achieve the effects of improving measurement accuracy, eliminating fluctuations in experimental parameters, and simplifying analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

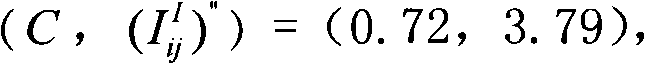

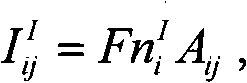

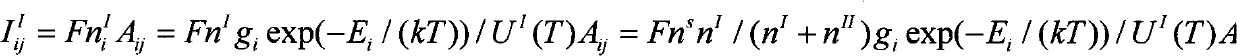

[0039] 1) Take six kinds of anthracite coal samples with known mass concentrations of each element as a group of calibration coal samples, and the mass concentrations of element nitrogen N in this group of coal samples are 0.24%, 0.29%, 0.51%, 0.85%, 1.10% respectively %, 1.14%. Load the calibration coal sample into the measuring device;

[0040] 2) Establish a calibration curve using the laser-induced plasma spectroscopy system installed on the coal conveyor belt: take the pulsed laser 1 as the excitation light source, and place the calibration coal sample 3 with known mass concentrations of each element in a protective atmosphere of air (also can be placed in N 2 , CO 2 or an atmosphere of an inert gas), the laser emitted from the laser is focused by the focusing lens 2 and acts on the surface of the calibration coal sample, generating plasma at the focal point, and collecting the plasma radiation optical signal in real time through the collecting lens 4, and the signal pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com