Method and system for testing high temperature tolerance and compatibility of optical fiber in oil

A test method and compatibility technology, applied in weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc., can solve the problems of mutual influence between optical fiber and transformer oil, and achieve small external environment influence, easy operation, high test temperature controllable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

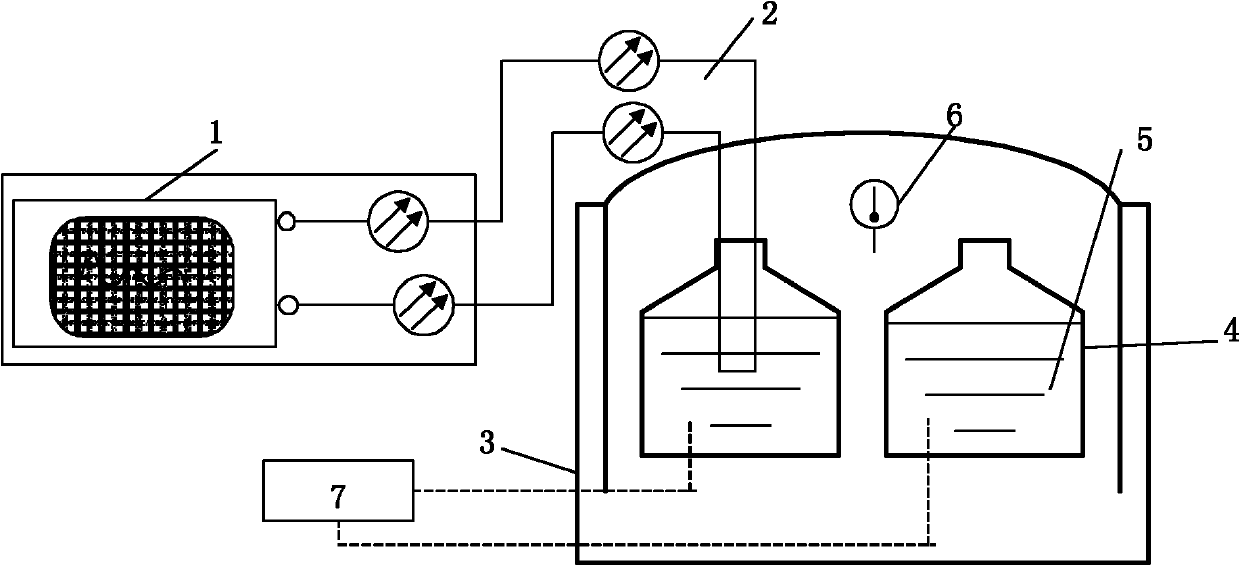

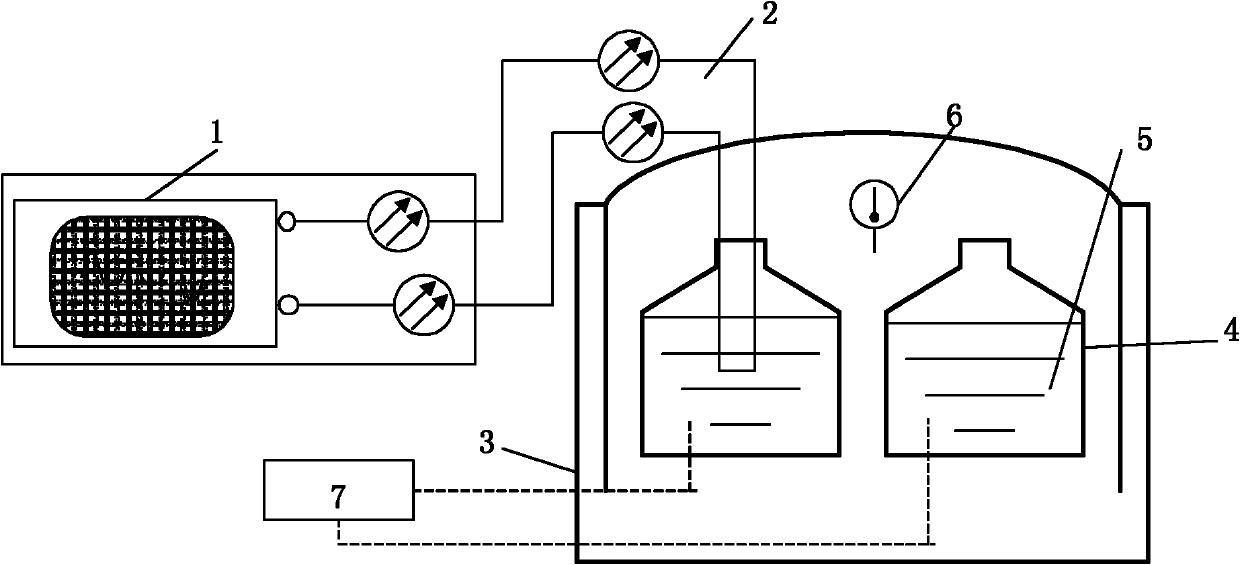

[0017] Markings in the attached drawings:

[0018] In the accompanying drawings, 1-optical fiber signal analysis device, 2-single-mode or multi-mode sensing optical fiber, 3-incubator, 4-closed container, 5-transformer oil, 6-temperature measuring instrument, 7-oil chromatography and oil characteristics Analyzer.

[0019] Embodiments of the present invention are further described below in conjunction with the accompanying drawings:

[0020] As shown in the accompanying drawings, a method and system for testing the high temperature resistance and compatibility of optical fibers in oil, including an optical fiber signal analysis device 1, a single-mode or multi-mode sensing optical fiber 2, an incubator 3, a closed container 4, and a transformer Oil 5, Temperature Measuring Instrument 6, Oil Chromatography and Oil Characteristic Analyzer 7. In this test system, optical fiber signal analysis device 1 and single-mode or multi-mode sensing optical fiber 2 realize the functions of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com