Turbine device with changeable runner

A turbine and flow channel technology, applied in mechanical equipment, engine components, combustion engines, etc., to achieve the effects of low cost, simple structure and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

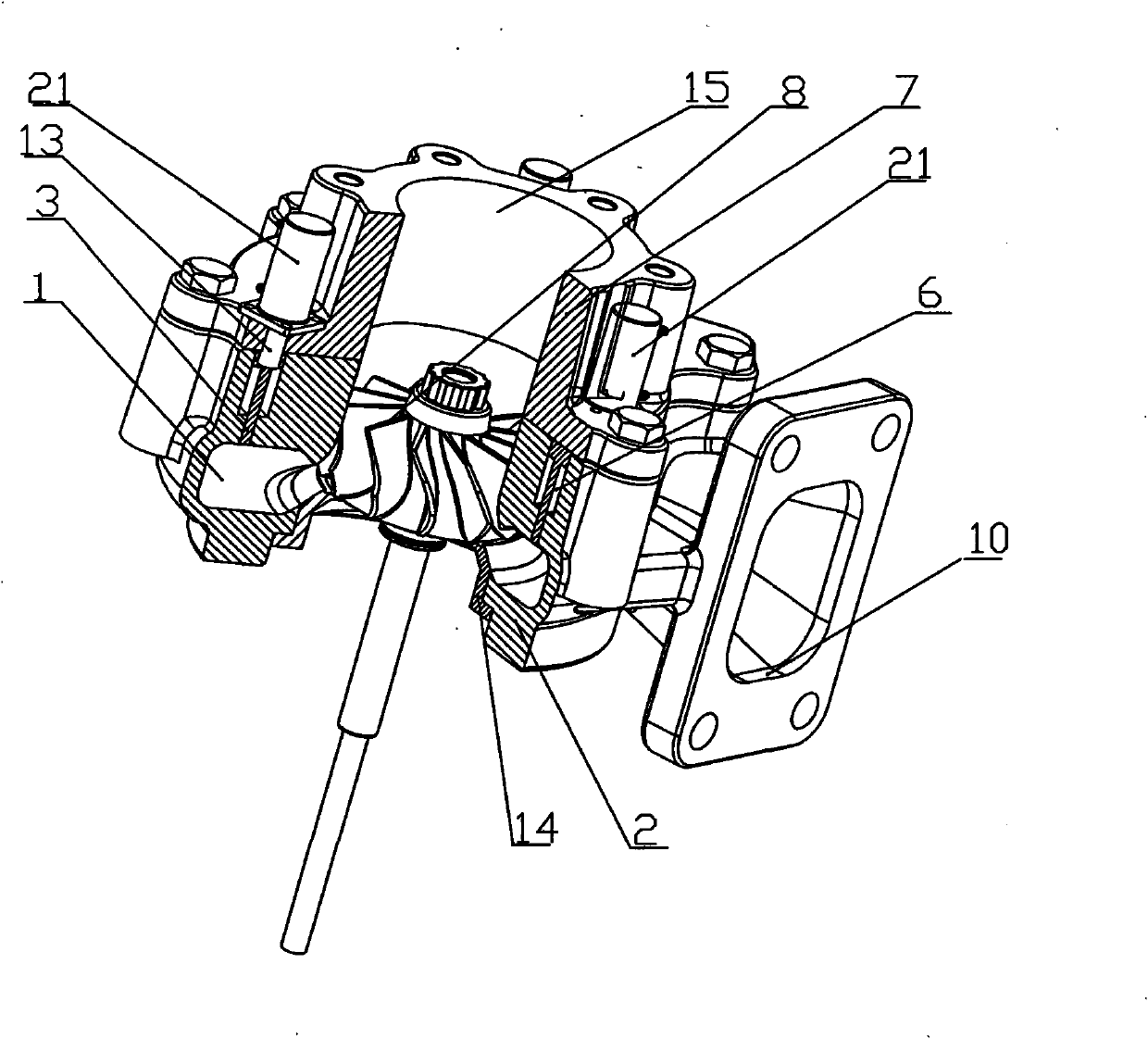

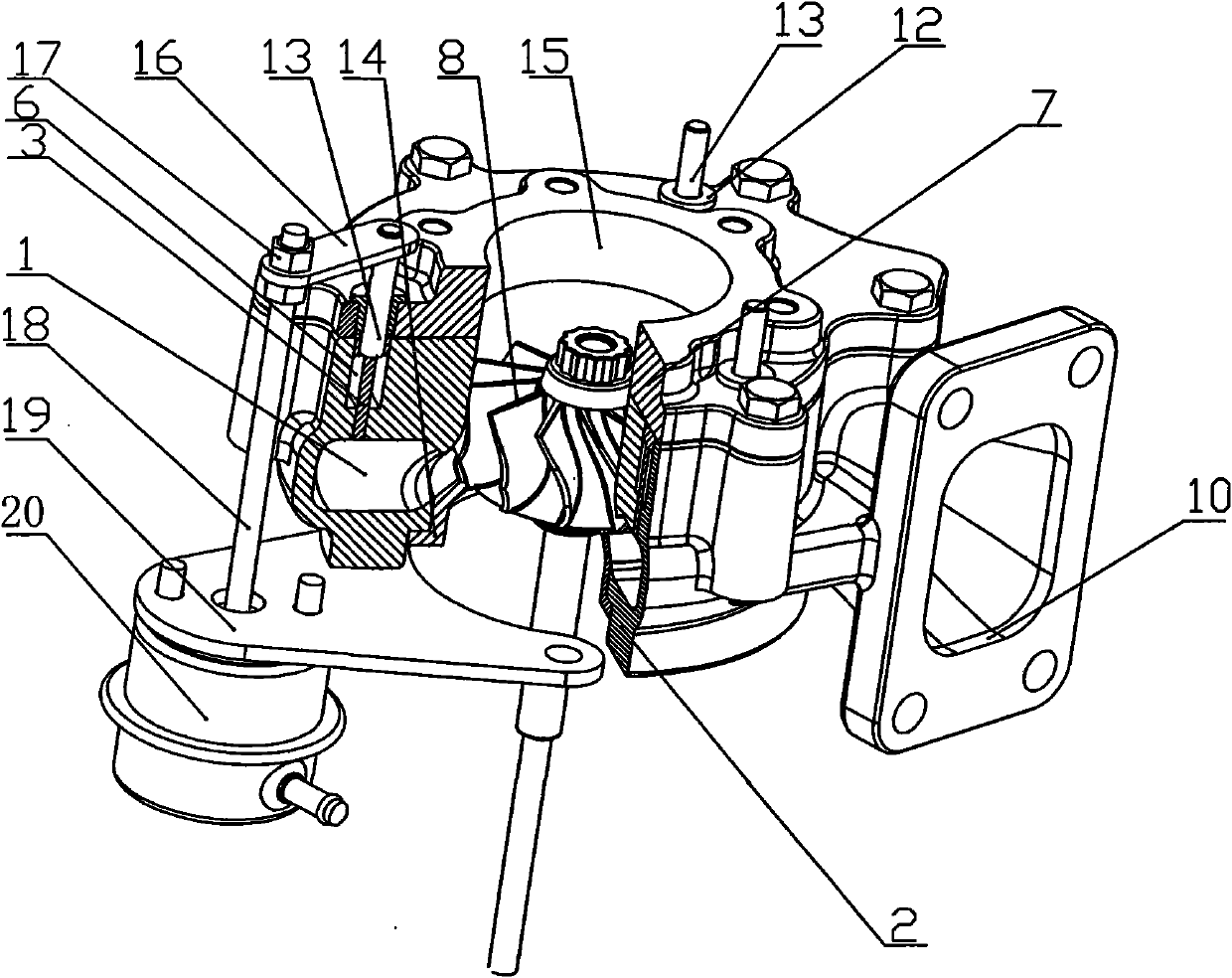

[0033] Embodiment 1, as attached figure 1 As shown, a variable channel turbine device includes a turbine volute 2, a turbine volute cover plate 7, and a turbine impeller 8. The turbine volute 2 is provided with a turbine volute flow channel 1, and the turbine volute flow channel 1 is There is a turbine volute inlet 10 and a turbine volute outlet 15, and the high-temperature exhaust gas discharged from the engine directly enters the turbine volute flow channel 1 along the turbine volute inlet 10 to provide power to the turbine impeller 8, in order to increase The intake energy at the turbine end sets the turbine volute channel 1 as a tapered type.

[0034] The spacer plate 3 of annular structure is arranged in the described turbine volute channel 1, and spacer plate 3 is positioned in the whole turbine volute channel 1, and described spacer plate 3 can move along the axial direction of turbine volute 2, and the spacer The board 3 is in drive connection with the control mechani...

Embodiment 2

[0044] Embodiment 2, as attached Figure 4As shown, the control mechanism 9 in Embodiment 1 can also be a hydraulic cylinder 21 , and the hydraulic rod of the hydraulic cylinder 21 is connected to the threaded rod 13 .

[0045] The height of the hydraulic cylinder 21 is limited by the height of the turbine volute flow passage 1, and the hydraulic cylinder 21 is controlled by a hydraulic pump connected to the engine, so as to effectively adjust the axial movement of the partition plate 3 in the annular groove 6 according to the engine working conditions;

[0046] When the engine is in the low speed range, the partition plate 3 is in a closed state driven by the hydraulic cylinder 21, and the engine exhaust gas entering from the turbine volute inlet 10 only flows along the direction of the inner flow 5, thereby pushing the turbine impeller 8 rotates, at this time, the outer runner 4 is in a closed state and no exhaust gas will flow through it.

[0047] Such as Figure 5 As sho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com