Combined box body used for hollow floor filling and manufacturing method thereof

A hollow floor and box technology, applied in the direction of floors, building structures, building materials, etc., can solve the problems of difficult guarantee of production quality, unfavorable popularization and application, and poor basic bonding, so as to ensure the pouring quality and building structure performance, easy promotion and application, and the effect of saving cement consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

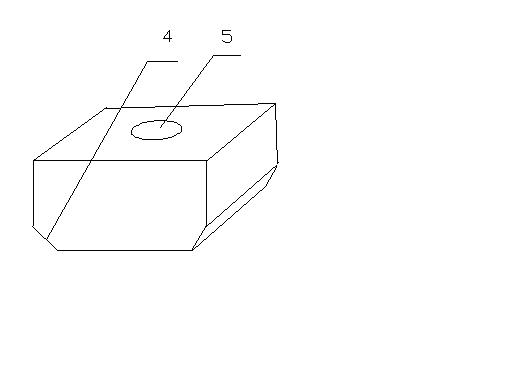

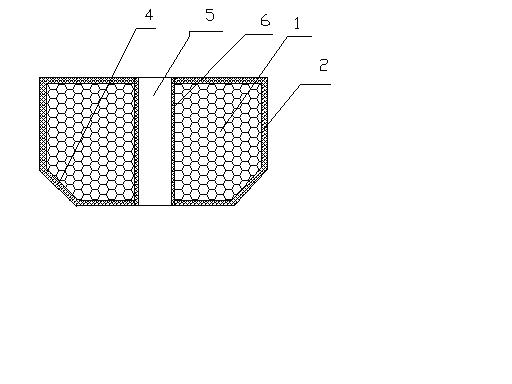

[0029] Such as figure 1 and figure 2 As shown, the hollow floor filling composite box of the present invention includes a polystyrene foam solid box 1, and the outer surface of the polystyrene foam solid box 1 is covered with a hard shell 2; the hard shell The layer is formed from a cement fiber mesh mortar containing a glass fiber mesh cloth into which stone powder is incorporated. According to the actual needs of the compressive strength, the glass fiber mesh layer can be provided with one or more layers. The two longitudinal edges of the bottom of the polystyrene foam solid box body 1 are poured into a bevel 4 . The composite box thus formed also has two longitudinal edges that are bevelled. The center of the polystyrene foam solid box 1 is provided with a cast-in-place material guide hole 5 , and a fiber mesh cloth layer 6 is attached in the cast-in-place material guide hole 6 .

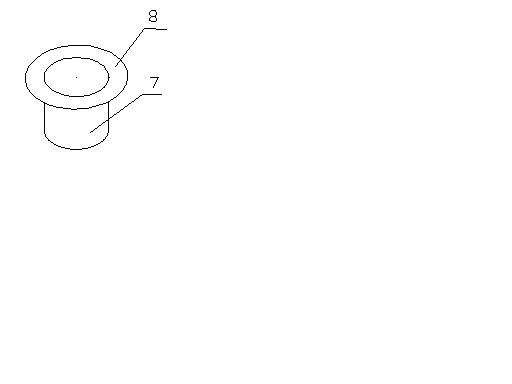

[0030] Such as image 3 As shown, the partial reinforcement in the present invention is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com