Diacetate electrostatic spinning solution based spinning method

A technology of electrospinning and diacetate, applied in the field of preparation of diacetate, can solve problems such as non-electrospinning, achieve the effects of small diameter, increase specific surface area, and save production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

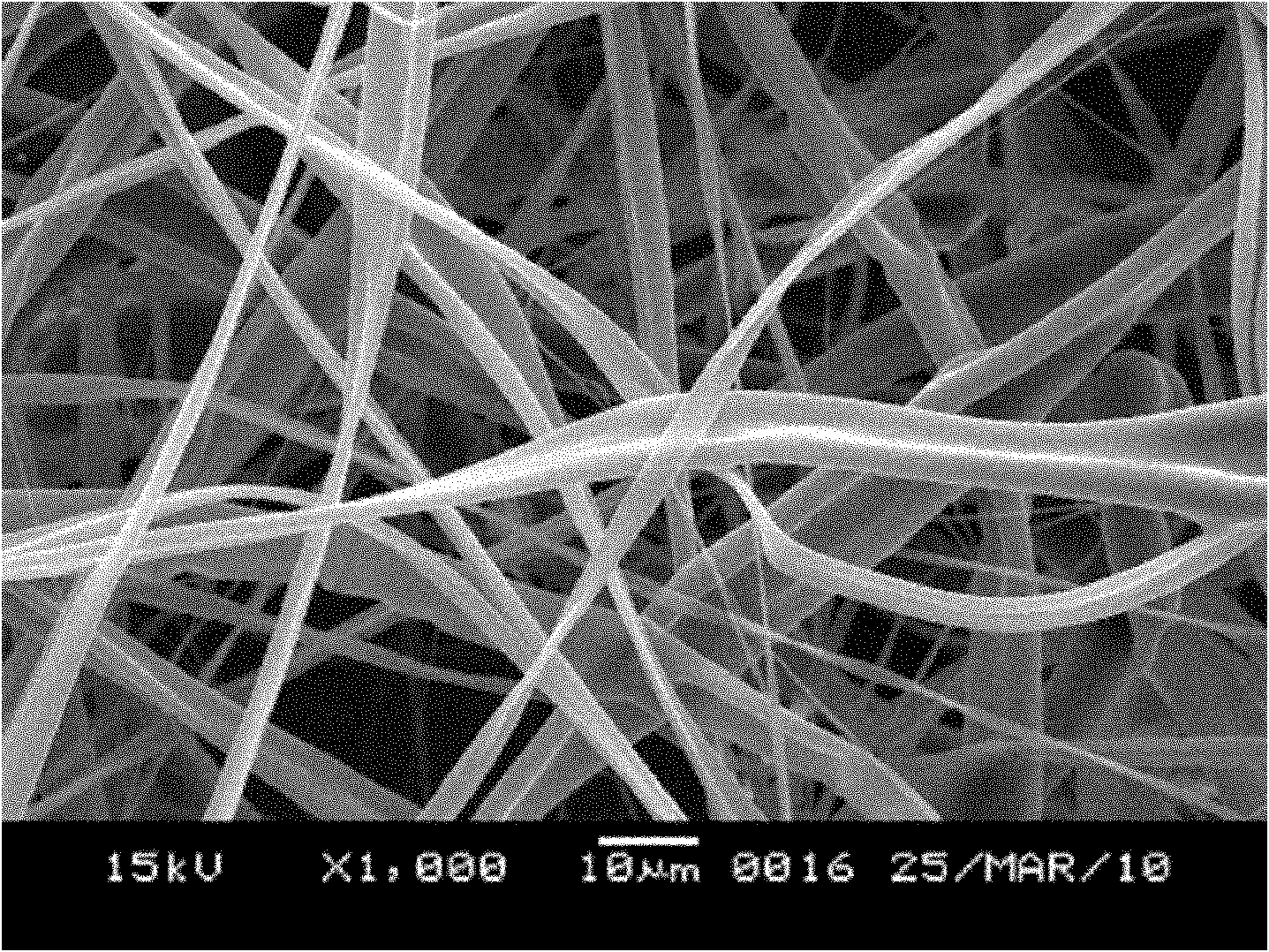

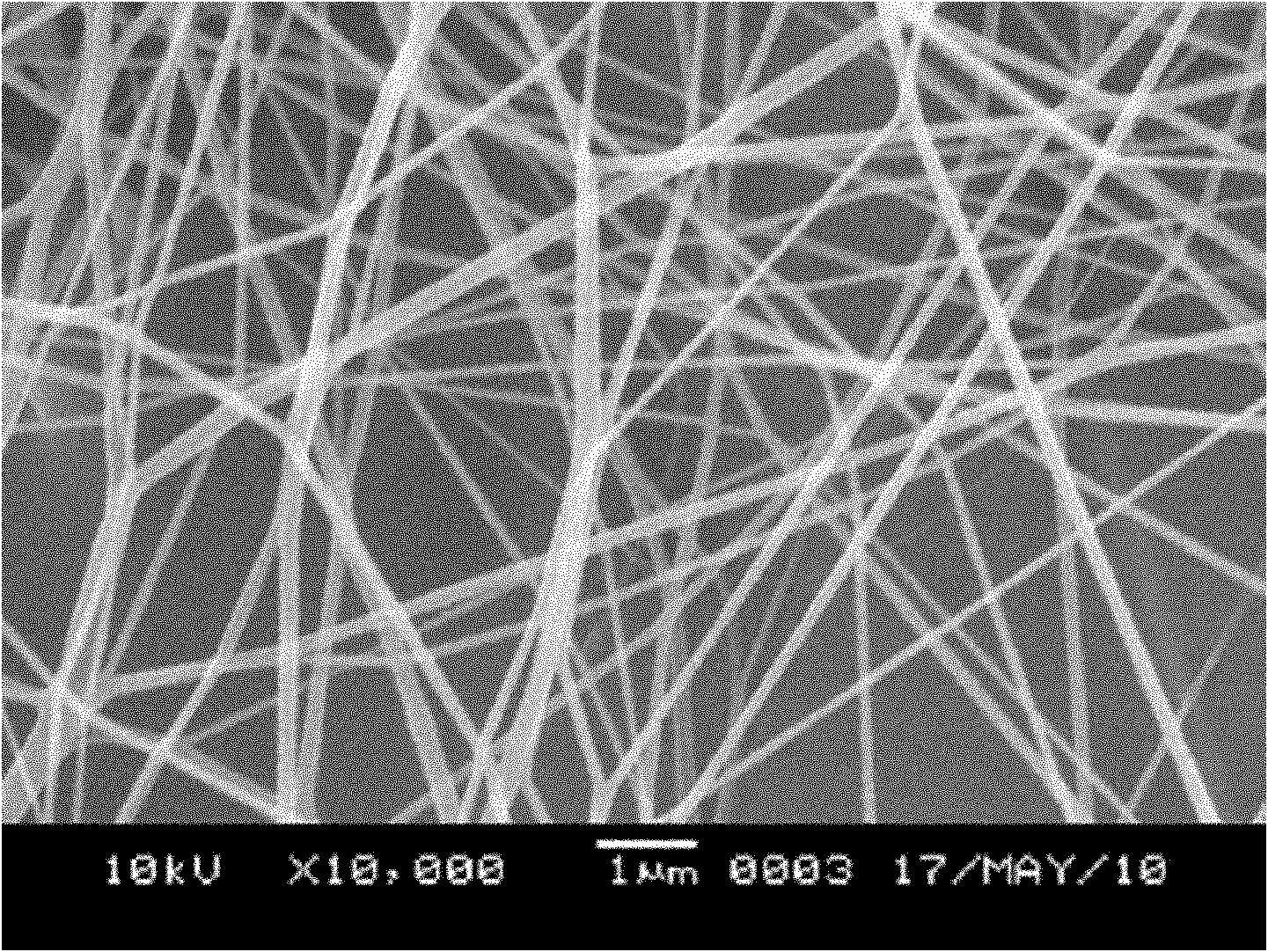

[0022] Spinning processing parameters: the applied voltage is 10-25kV, the receiving distance is 10-30cm, the solution flow rate is 3ml / h, and the variation range of CA concentration is 4-12wt%. Select the optimal combination: the applied voltage is 18kV, the receiving distance is 20cm, and the solution concentration is 8%. The volume ratio of the mixed solvent was set at 2:1, wherein the amount of acetone was 40 mL, and the amount of DMAC was 20 mL. The prepared nanofibrous membrane is similar to a non-woven mat. Through electron microscope analysis, the external morphology and structure of the fiber obtained are as follows: image 3 shown. The invention and figure 1 There are clear differences in the fiber morphology shown. After testing, the fineness of the spun diacetate nanofiber is 0.20-0.5 μm, the unevenness of fineness is 20%, and the longitudinal shape of the fiber is cylindrical.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com