Oil stain used for coloring wood lacquer, preparation method and coating method thereof

A colorant, wood lacquer technology, applied in the device, coating, special surface and other directions of coating liquid on the surface, can solve the problems of adhesion, precipitation, and easy to thicken when the colorant is stored for a long time, so as to solve the adhesion force Problems, flexible choices, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The oil-based coloring agent for black and brown wiping is mainly composed of the following raw materials by weight percentage:

[0050] Short oleoresin 15%

[0051] Thixotropic resin 15%

[0052] S-100 15%

[0053] BYK106 2%

[0054] Black brown powder (amba powder) 25%

[0055] Filler 28%

[0056] Total 100%

[0057] The short oleoresin is an alkyd resin, and the technical requirements are: solid content by weight of 70±1%, acid value≤8.6mgKOH / g, Gardner chroma≤4, and Setal 543HV XX-70 of nuplex company can be used.

[0058] The thixotropic resin is an alkyd resin, and the technical requirements are: the weight solid content is 60±2%, the acid value (by solid content)≤25mg KOH / g, the Gardner color (50% soluble in xylene)≤ 10. Resin content ≈7%, Worlee Thix MH 439 from Worlee Company can be used.

[0059] The filler is aromatic hydrocarbon solvent S-100.

[0060] The specific production process is as follows: firstly, weigh short oleoresin, thixotropic resin an...

Embodiment 2

[0065] The oil-based coloring agent for medium-yellow UV-curable roller coating is mainly composed of the following raw materials by weight percentage:

[0066] Short oil resin 15%, thixotropic resin 15%, aromatic solvent S-100 30%, BYK1062%, medium yellow powder 12% (organic toner), filler 26%.

[0067] The short oleoresin is an alkyd resin, and the technical requirements are: solid content by weight of 70±1%, acid value≤8.6mgKOH / g, Gardner chroma≤4, and Setal 543HV XX-70 of nuplex company can be used.

[0068] The thixotropic resin is an alkyd resin, and the technical requirements are: the weight solid content is 60±2%, the acid value (by solid content)≤25mg KOH / g, the Gardner color (50% soluble in xylene)≤ 10. Resin content ≈7%, Worlee Thix MH 439 from Worlee Company can be used.

[0069] The filler is aromatic hydrocarbon solvent S-100.

[0070] Concrete manufacturing process is with embodiment 1.

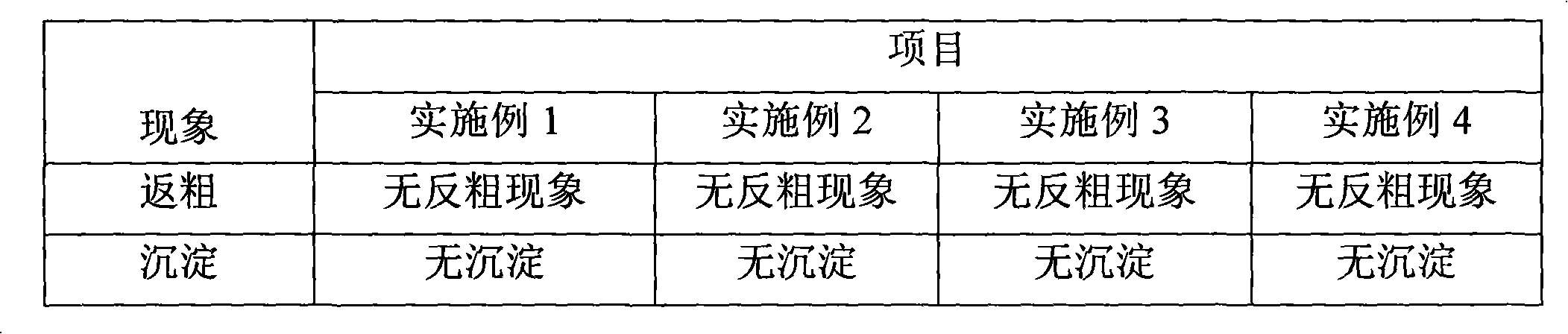

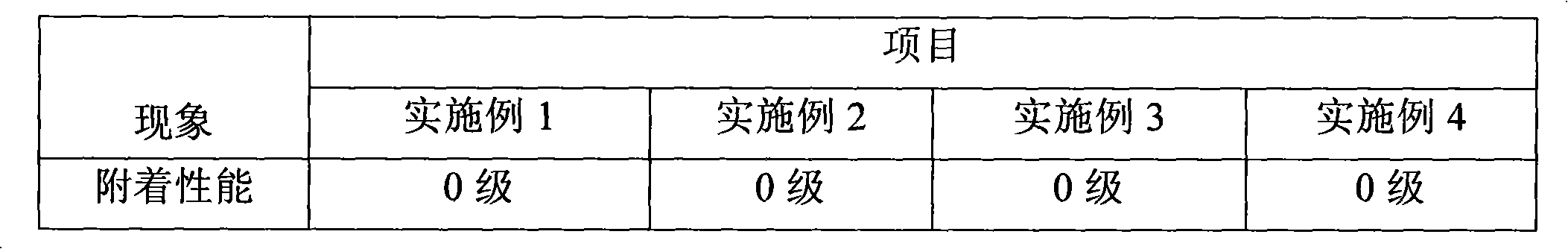

[0071] The test results are as follows:

[0072] The solid content is 30...

Embodiment 3

[0075] The oily coloring agent for reddish-brown wiping is mainly composed of the following raw materials by weight percentage:

[0076] Short oleoresin 10%, thixotropic resin 10%, aromatic solvent S-100 30%, BYK106 2%, reddish brown powder (amba powder) 25%, filler 23%.

[0077] The short oleoresin is an alkyd resin, and the technical requirements are: weight solid content of 70±1%, acid value≤8.6mgKOH / g, Gardner chroma≤4, and Setal 543 HV XX-70 of nuplex company can be used .

[0078] The thixotropic resin is an alkyd resin, and the technical requirements are: the weight solid content is 60±2%, the acid value (by solid content)≤25mg KOH / g, the Gardner color (50% soluble in xylene)≤ 10. Resin content ≈7%, Worlee Thix MH 439 from Worlee Company can be used.

[0079] The filler is aromatic hydrocarbon solvent S-100.

[0080] Concrete manufacturing process is with embodiment 1.

[0081] The test results are as follows:

[0082] The solid content is 32.5% GB / T 1725-79 (metho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com