Forging mold for cantilever type hardware fitting base of electrified railway contact network parts

A technology of electrified railway and catenary, which is applied in the field of forging molds, can solve the problems of high scrap, quality not up to the requirement, and small contact area of ears, etc., and achieve the effect of increasing contact area, reducing manufacturing cost, and good force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

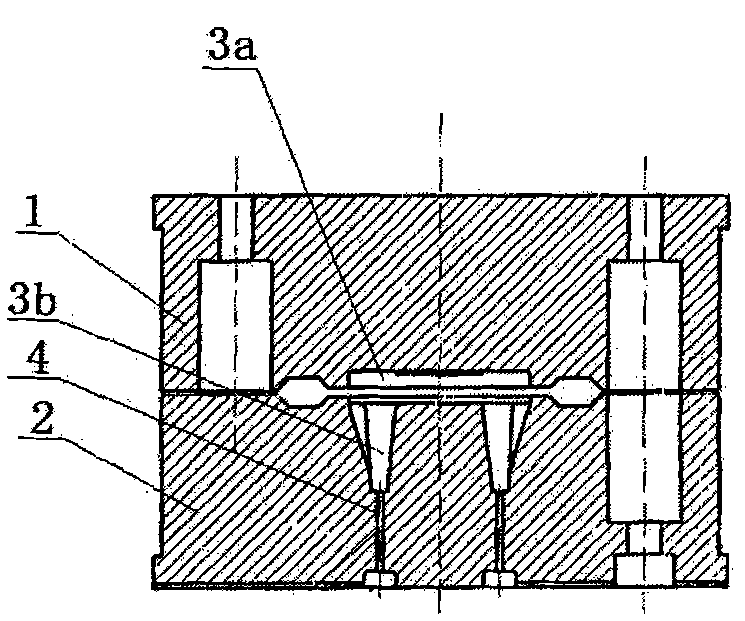

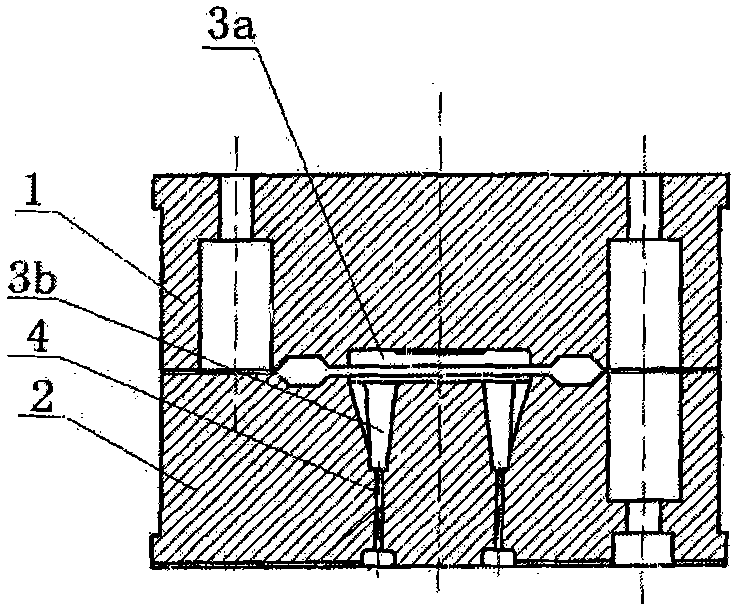

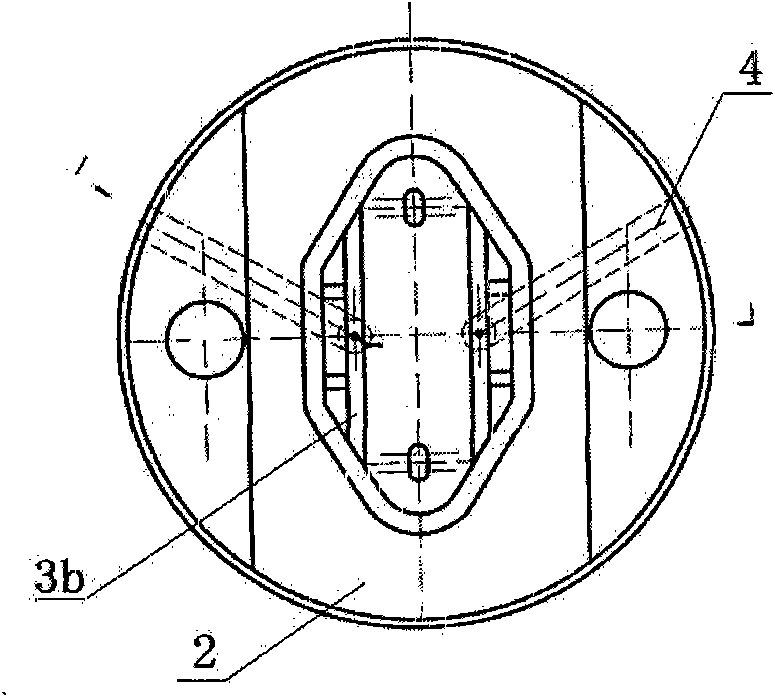

[0012] like figure 1 , 2 As shown, it includes an upper mold 1 and a lower mold 2. The cavities of the upper mold 1 and the lower mold 2 are combined to form the cavity 3 of the metal fitting base. The cavity 3 is composed of the base 3a and the ears 3b symmetrically arranged on both sides. The taper in the middle of the inner surface of the cavity ear 3b is 1-2°.

[0013] The inner wall of the cavity 3 is provided with an exhaust channel 4 that communicates with the outside world. The exhaust channel 4 is located at the bottom of the cavity 3, one end communicates with the cavity 3, and the other end goes vertically down to the lower end surface of the lower die 2. It extends to the side and communicates with the outside world through the side wall of the lower mold 2 . During forging, since an exhaust channel 4 is provided in the cavity 3, the air in the cavity 3 is exhausted, making it easier to punch the shape, and the mold can still be pulled out smoothly when the draft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com