Method for processing and recycling aquaculture water in intensive culture pond

A technology of breeding water and ponds, applied in the fields of application, fish farming, animal husbandry, etc., can solve the problems that affect the healthy and sustainable development of the shrimp farming industry, the amount of waste water and waste is astonishing, and the consumption of water resources is large, so as to achieve high use value , neat specifications, and the effect of increasing the breeding output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

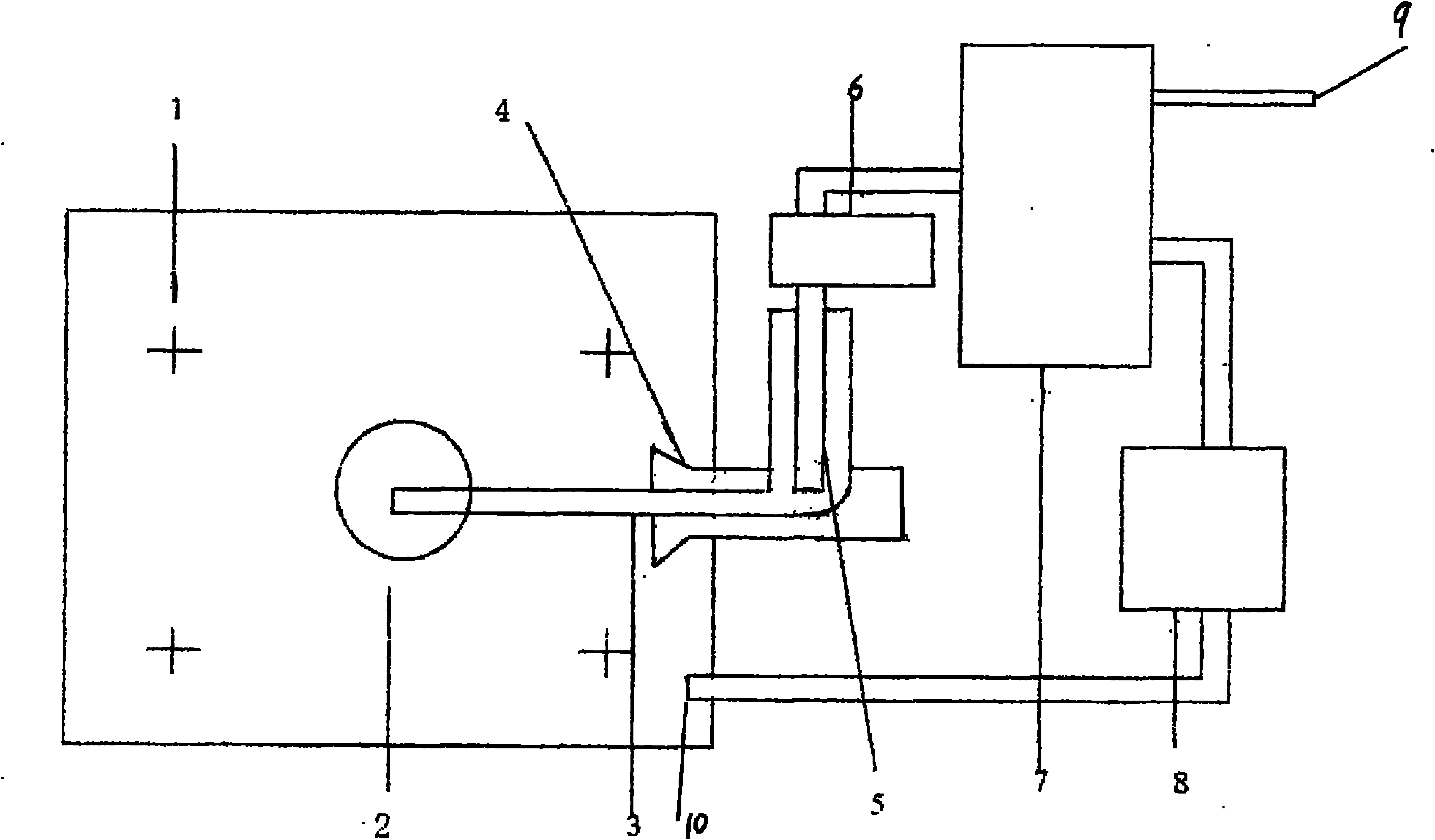

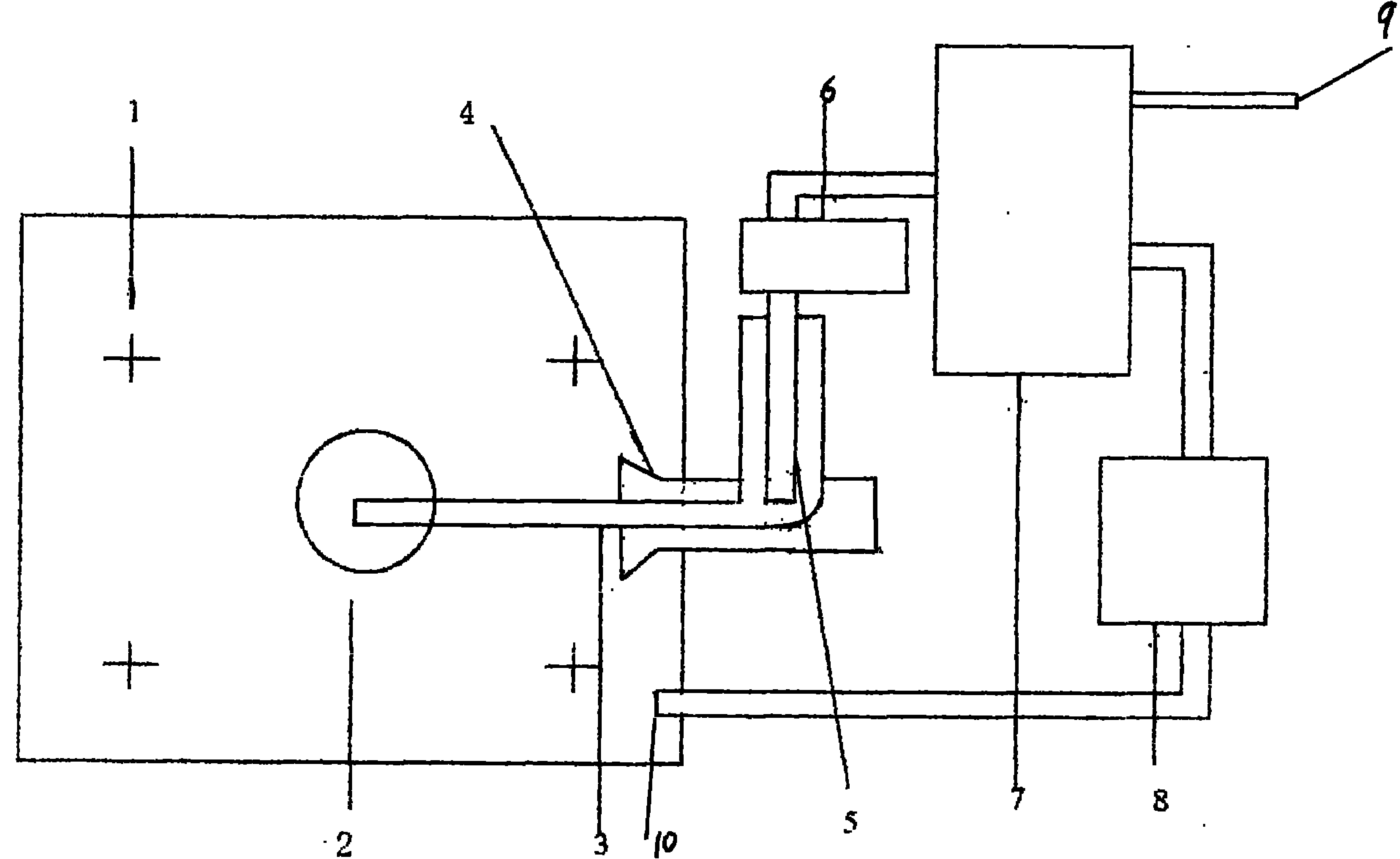

[0010] ①Two areas are 0.23hm 2 , with a pond depth of 2.3m and a water depth of 1.6m in the winter shed intensive culture pond of Litopenaeus vannamei, with a stocking density of 3 million fish / hm 2 , the output is 30000-37500kg / hm 2 , Each pond is equipped with bottom oxygenation facilities, and at the same time, 4-6 waterwheel aerators 1 are equipped at the four corners of the pond. After 30 days of breeding, the waterwheel aerator 1 is started to form a circulation, and the pollutants are concentrated to the central sewage discharge port 2;

[0011] ②In each pond, a PVC pipe with an inner diameter of 26.4cm is installed at the central sewage outlet 2, and the sewage pipe 3 is connected to the gate 4 of the drainage gate; a PVC elbow with an inner diameter of 26.4cm is installed at the gate 4, and a 26.4cm inner diameter is inserted PVC pipe;

[0012] ③ On the dams near the drainage gates of the two ponds, 6 sets of water pumps with a power of 3kw and a head of about 5m a...

Embodiment 2

[0015] ①The four areas are 0.23hm respectively 2 , the depth of the pool is 2.5m, the water depth is 2.0m, and the intensive culture pond of the oblique grouper, the stocking density is 30,000 fish / hm 2 , output is 15000kg / hm 2 About 4-6 sets of water wheel aerators are installed at the four corners of each pond. After 60 days of breeding, the water wheel aerator 1 is turned on to form a circulation, and the pollutants are concentrated to the central sewage outlet 2;

[0016] ②In each pond, a PVC pipe with an inner diameter of 26.4cm is installed at the central sewage outlet 2, and the sewage pipe 3 is connected to the gate 4 of the drainage gate; a PVC elbow with an inner diameter of 26.4cm is installed at the gate 4, and a 26.4cm inner diameter is inserted PVC pipe;

[0017] ③On the dams near the drainage gates of the four ponds, 3 pumps with a power of 3kw and a lift of about 5m are equipped to pump water from the PVC pipes into the foam separator 7. The pumping hoses are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com