Sound absorbing skin material and sound absorbing material utilizing the same

A technology of sound-absorbing properties and sound-absorbing materials, applied in the field of sound-absorbing materials, can solve problems such as weak surface strength, reduced durability of molding shape compliance, fuel saving, and unfavorable weight reduction, and achieve good formability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

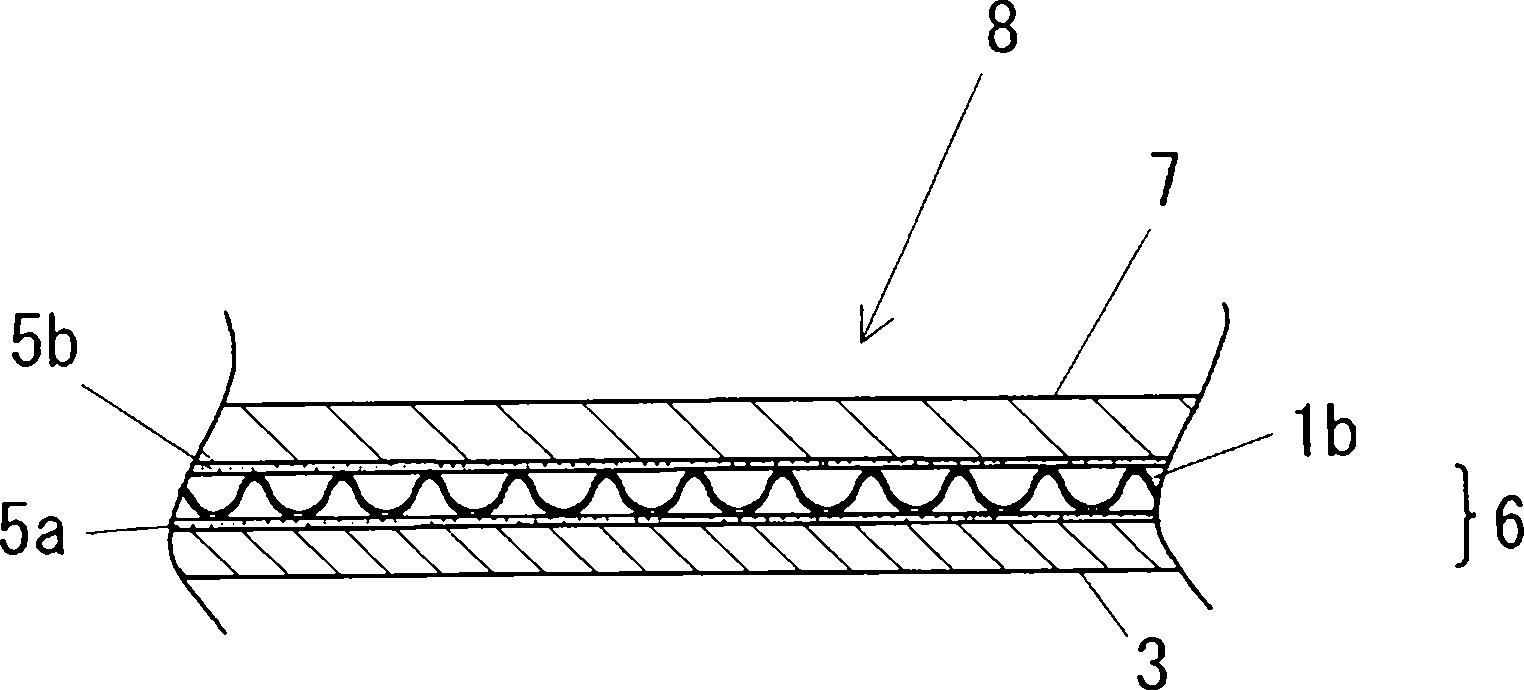

[0117] The weight per unit area made of polyester fiber by needle punching method is 80g / m 2 The back of the fiber sheet, according to the coating amount to reach 15g / m 2 After spraying a hot-melt adhesive made of hot-melt polyamide (melting point: 130°C), crepe paper made of 60% by mass softwood pulp and 40% by mass hardwood pulp was laminated on the fiber sheet. On the coated surface of the hot melt adhesive, the laminate is pressed with a hot roller with a surface temperature adjusted at 140-150°C, and then pressed with a cold and hot roller to obtain a crepe-processed A sound-absorbing surface material composed of a laminate of paper and fiber sheets. As the above-mentioned creped paper, four types of creped paper shown below were used.

[0118] 1: The wrinkle rate is 15%, and the weight per unit area is 15g / m 2

[0119] 2: The wrinkle rate is 15%, and the weight per unit area is 40g / m 2

[0120] 3: The wrinkle rate is 30%, and the weight per unit area is 15g / m 2

...

Embodiment 2

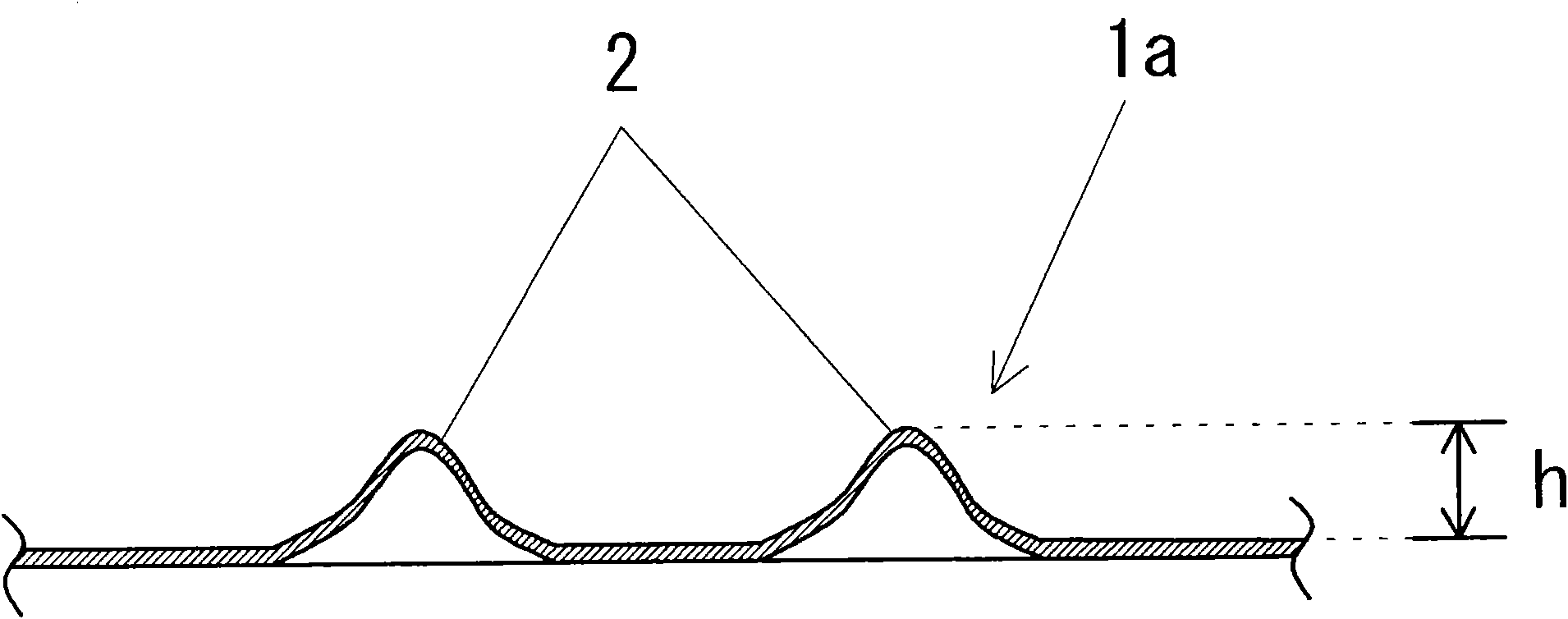

[0124] The creped paper in Example 1 was replaced with embossed paper to obtain a sound-absorbing surface material and a sound-absorbing material. In addition, as a sound-absorbing performance test, a 10-mm-thick flat-shaped sound-absorbing material was molded at the same time. As the above-mentioned embossed paper, four kinds of embossed papers shown below were used.

[0125] 1: The protrusion height is 0.2mm, and the number of protrusions is 150 / cm 2 , and the weight per unit area is 15g / m 2

[0126] 2: The protrusion height is 0.2mm, and the number of protrusions is 150 / cm 2 , and the weight per unit area is 40g / m 2

[0127] 3: The protrusion height is 1.5mm, and the number of protrusions is 20 / cm 2 , and the weight per unit area is 15g / m 2

[0128] 4: The protrusion height is 1.5mm, and the number of protrusions is 20 / cm 2 , and the weight per unit area is 40g / m 2

Embodiment 3

[0168] Use polyester fibers and made by needle punching with a weight per unit area of 70g / m 2 Fiber sheet, and according to the coating amount up to 10g / m 2 After spraying a hot-melt adhesive made of hot-melt polyester (melting point: 130° C.) on one side of the fiber sheet, a fiber sheet made of 80% by mass of softwood pulp and 20% by mass of hardwood pulp was sprayed. Crepe processed paper (crepe rate: 30%, weight per unit area: 20g / m 2 ) is laminated on the surface coated with the hot melt adhesive, and after being laminated with a hot roller whose surface temperature is adjusted to 140-150°C, it is laminated with a cooling roller, thereby bonding the creped paper to the fiber sheet superior. Next, 40 parts by mass of acrylate / methacrylate copolymer emulsion (solid content: 40%, MFT (film forming temperature): 4°C), 20 parts by mass of copolymerized polyester as a hot-melt adhesive A mixed solution composed of resin (melting point: 110°C, particle size: 100-150μm), 40...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com