Method for directly utilizing liquid-state blast furnace slag to manufacture glass ceramics

A technology of glass-ceramics and blast furnace slag, which is applied in the field of glass-ceramics made from liquid blast-furnace slag, can solve the problems of high raw material cost of slag glass-ceramics, high production cost of slag glass-ceramics, lack of market competitiveness of products, etc. Cost and pollution problems, saving water resources for flushing slag, and saving capital investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

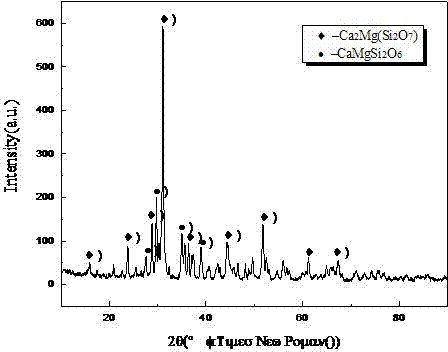

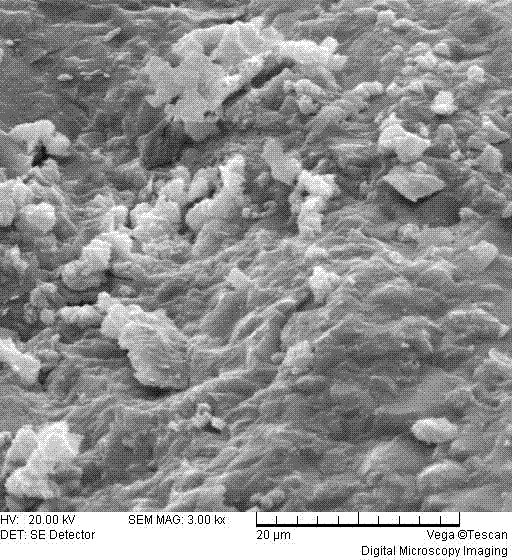

Image

Examples

Embodiment Construction

[0028] In addition to the high-temperature liquid blast furnace slag, the production raw material of the present invention also has the additive SiO 2 (The actual production uses SiO 2 96% quartz sand). In order to ensure strong crystallization ability of glass-ceramics and the highest utilization rate of blast furnace slag, liquid blast furnace slag and SiO 2 The mass ratio of the blast furnace slag is 100:10-30, that is, 10wt%-30wt% quartz sand is added to the blast furnace slag, and the utilization rate of the blast furnace slag reaches 75%-90%.

[0029] The concrete steps of this method are:

[0030] 1) The high-temperature blast furnace slag produced in the blast furnace and the SiO slag that is still in the liquid state and the SiO 2 Add to the batching furnace and mix evenly, and preheat the batching furnace to the blast furnace slag discharge temperature before feeding (generally, the slag discharge temperature of blast furnace slag is about 1450°C);

[0031] 2) Tran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com