Transmission device of mechanical elbow rod type servo press

A technology of servo presses and transmission devices, applied in presses, stamping machines, manufacturing tools, etc., can solve the problems of inflexible design of the stroke of the pressure head, inability to adjust the pressure curve according to actual work needs, and low transmission efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

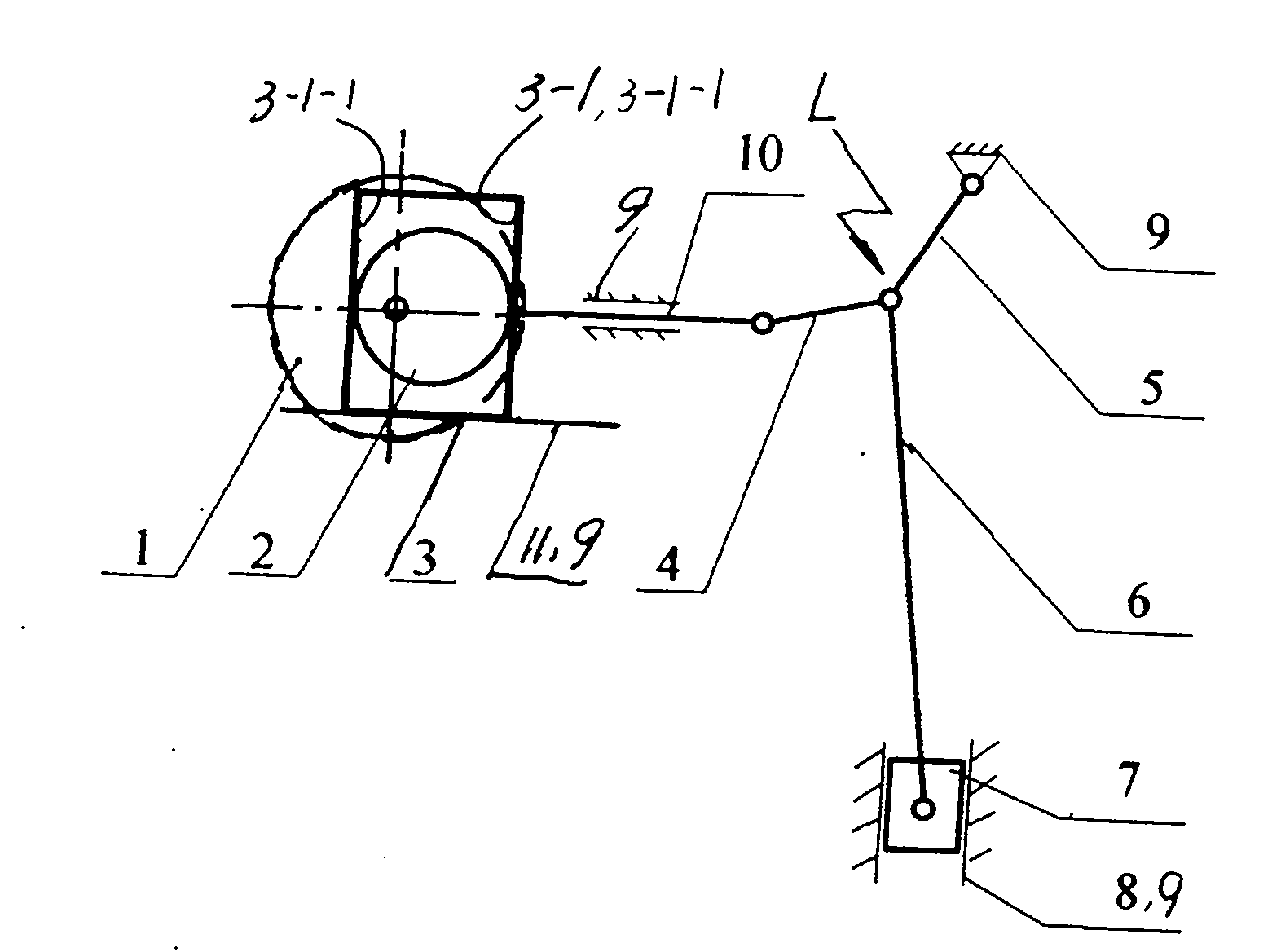

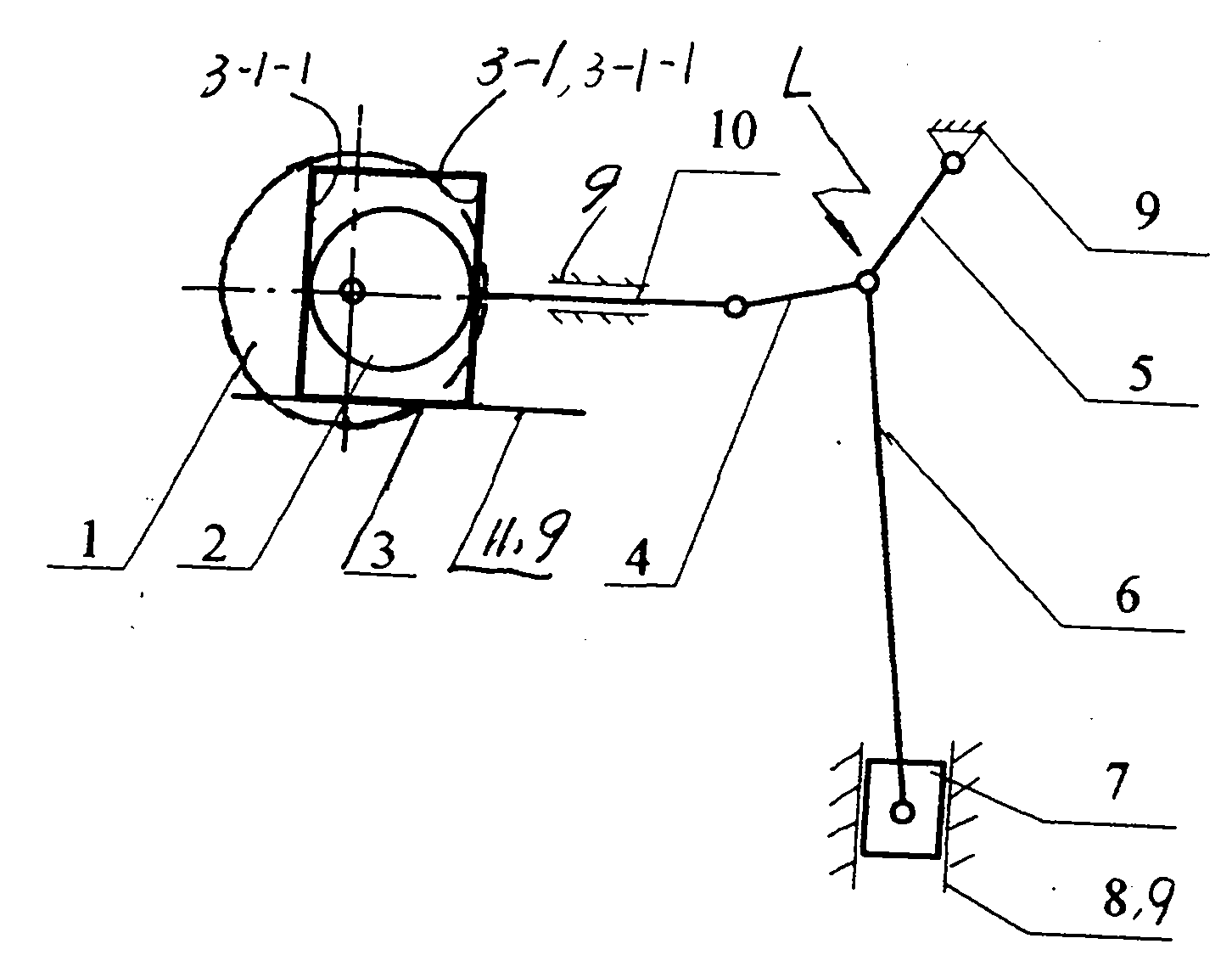

[0015] Example 1, as attached figure 1 Shown.

[0016] A transmission device of a mechanical toggle-type servo press includes a servo motor 1 controlled by a PLC programmable controller, a swing rod 5 hinged with a body 9, an upper link 4, and a vertical slider 7 hinged The lower link 6, and the horizontal reciprocating link 10 articulated by the upper link 4 of the toggle link mechanism L composed of the swing link 5, the upper link 4 and the lower link 6 through the same hinge axis, further includes:

[0017] -Horizontal sliding block 3; The horizontal sliding block 3 is slidingly fitted with a horizontal guide rail 11 connected to the fuselage 9; The horizontal sliding block 3 has a rectangular blind hole 3-1; The horizontal sliding block 3 and a horizontal reciprocating link 10 connection;

[0018] -Equal-diameter cam 2; The equal-diameter cam 2 is statically connected with the servo motor 1 in a shaft hole; the equal-diameter cam 2 and the rectangular blind hole 3-1 of the hori...

Embodiment 2

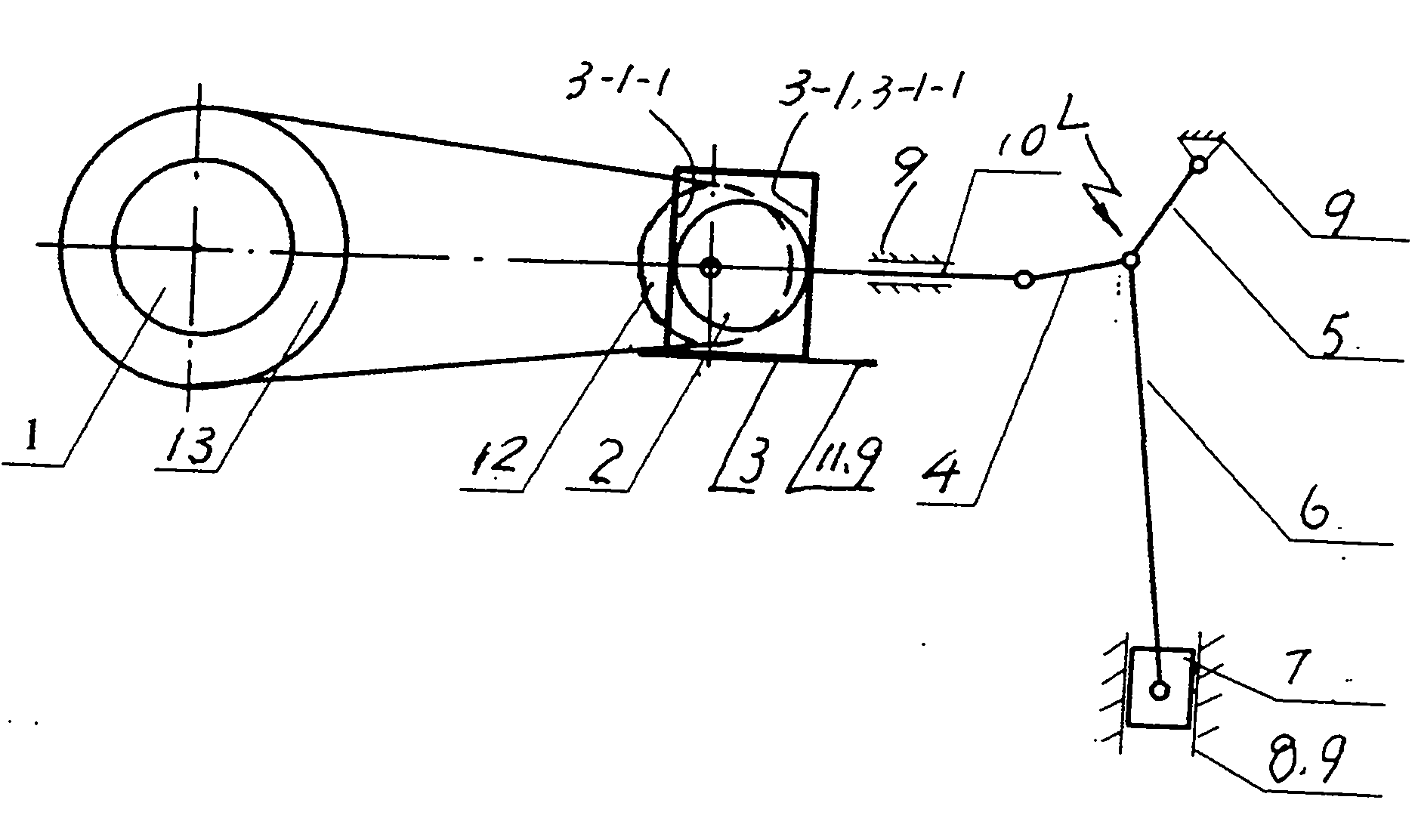

[0020] Example 2, as attached figure 2 Shown.

[0021] A transmission device of a mechanical toggle-type servo press includes a servo motor 1 controlled by a PLC programmable controller, a swing rod 5 hinged with a body 9, an upper link 4, and a vertical slider 7 hinged The lower link 6, and the horizontal reciprocating link 10 articulated by the upper link 4 of the toggle mechanism L composed of the swing link 5, the upper link 4 and the lower link 6 through the same hinge axis, further includes:

[0022] -Horizontal sliding block 3; The horizontal sliding block 3 is slidingly fitted with a horizontal guide rail 11 connected to the body 9; The horizontal sliding block 3 has a rectangular through hole 3-1; The horizontal sliding block 3 and the horizontal reciprocating link 10 connection;

[0023] -Equal-diameter cam 2; said equal-diameter cam 2 abuts against two parallel vertical inner sides 3-1-1 of the rectangular through hole 3-1 of the horizontal slider 3.

[0024] It also inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com