Board and board processing equipment

A kind of processing equipment and wood board technology, applied in the direction of wood compression, etc., can solve the problems affecting the appearance, etc., and achieve the effect of good feeding speed and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

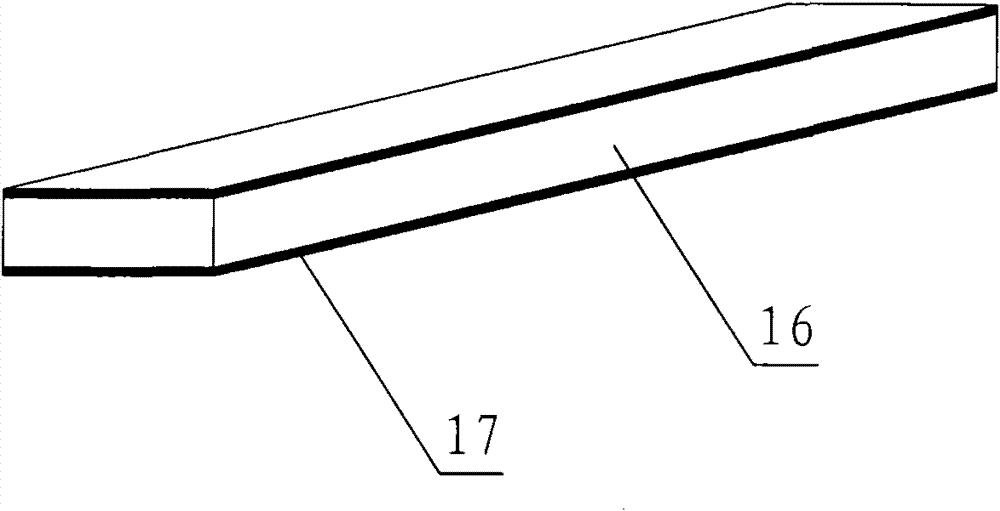

[0027] Embodiment 1: A wooden board, including a strip-shaped body 16 having a front, a back and a side end surface. The two sides of the strip-shaped body 16 in the length direction are integrally provided with a hardness layer 17 formed by roller friction, and the hardness layer 17 is hard. Inside the elongated body, the tube holes on the surface of the hardness layer 18 are in a closed state;

Embodiment 2

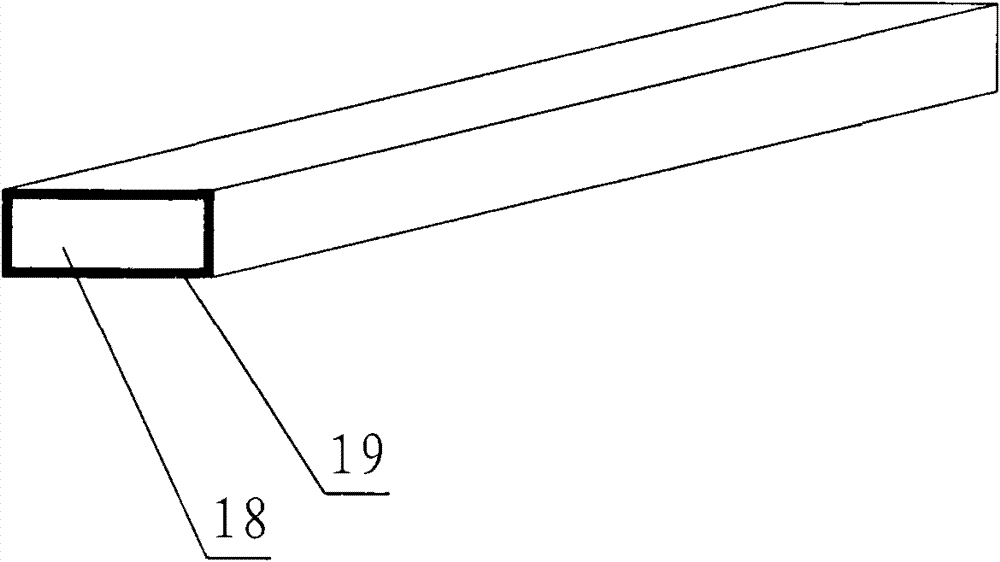

[0028] Embodiment 2: A kind of wooden board, comprises the elongated main body 18 that has front, back and side end surface, and the four faces of elongated main body 18 longitudinal directions are integrally provided with the hardness layer 19 that roller friction forms, and hardness layer 19 surface hardness Harder than the inside, the tube holes on the surface of the hardness layer 19 are in a closed state;

Embodiment 3

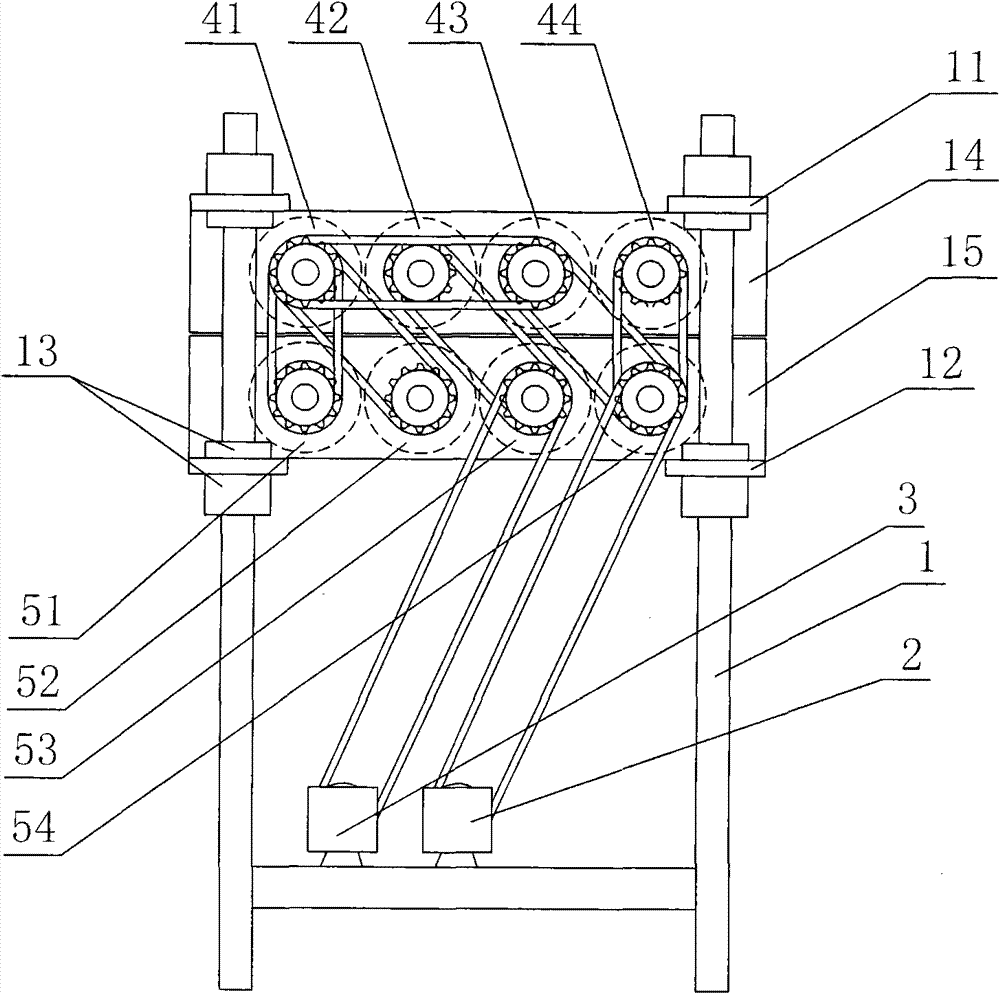

[0029]Embodiment 3: As shown in the figure, a kind of wood processing equipment includes a bracket 1, a first motor 2 and a second motor 3, and the bracket 1 is provided with an upper support plate 11 and a lower support plate 12 and is connected with a nut 13. The support 1 is fixedly connected, the upper support plate 11 is fixedly provided with an upper connection plate 14, the lower support plate 12 is fixedly provided with a lower connection plate 15, and the upper connection plate 14 is axially connected with four upper rollers arranged side by side, respectively. Cylinder 41, upper cylinder 42, upper cylinder 43, upper cylinder 44, the lower connecting plate 15 upper shaft is connected with four positions and the lower cylinder corresponding to the upper cylinder one by one, respectively lower cylinder 51, lower cylinder 52, lower cylinder 53, The lower drum 54, the lower drum 54, the upper drum 44 and the upper drum 43 are connected by sprockets to form the first set of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com