Novel low-carbon veneer and manufacture method thereof

A manufacturing method and technology of plywood, applied in the field of decorative materials, can solve problems such as shortage of wood, achieve the effect of protecting the environment and solving the shortage of wood resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

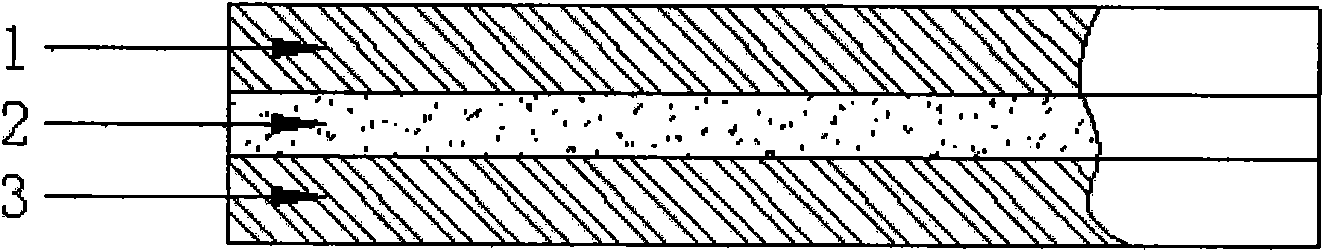

[0028] Such as figure 1 As shown, a new low-carbon plywood is a three-layer structure, including a wooden layer 1, a magnesite gelled flame-retardant layer 2, and a wooden layer 3, and the plywood is formed by compounding between layers.

[0029] The main components of the magnesite gelled flame retardant layer 2 are magnesium chloride and magnesium oxide, and the magnesite gelled flame retardant layer 2 is also filled with reinforcing materials such as plant fibers such as sawdust or peanut shell powder, glass fibers, modifiers, and other minerals. Extract. The wooden layers 1 and 3 are treated with flame retardant treatment.

[0030] The manufacture method of above-mentioned low-carbon novel plywood is:

[0031] a, the wood is processed into a plywood wood layer 1 and a wood layer 3 with a thickness of 4mm;

[0032] b. Press magnesium chloride, magnesium oxide, perlite, sawdust or peanut shell powder into a magnesite gelled flame-retardant layer 2 with a thickness of 3mm;...

Embodiment 2

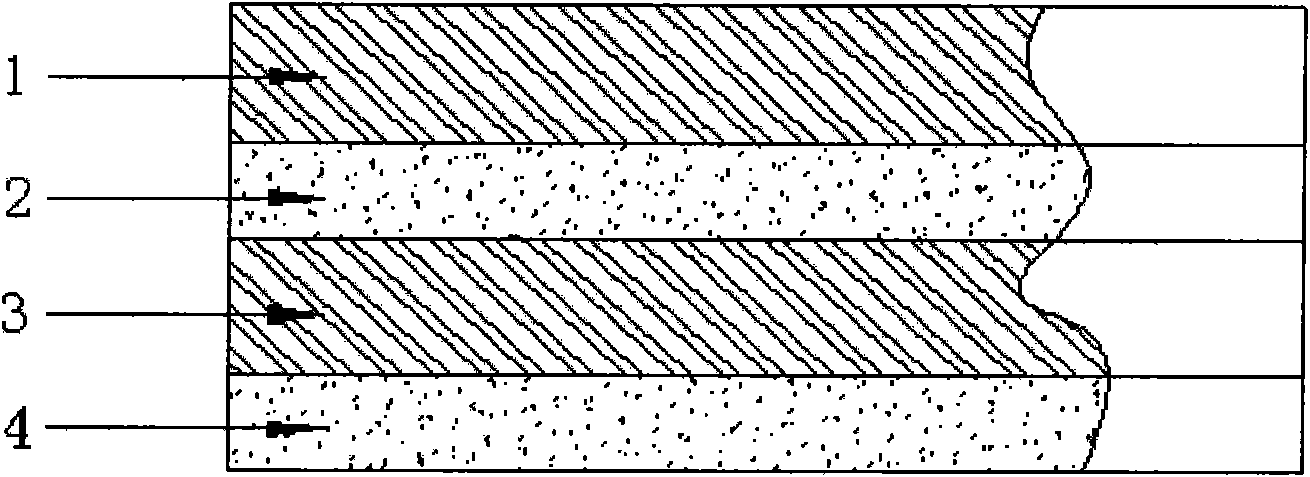

[0036] Such as figure 2 As shown, a new low-carbon plywood is a four-layer structure, including a wooden layer 1, a magnesite gelled flame-retardant layer 2, a wooden layer 3, and a magnesite gelled flame-retardant layer 4, and the plywood is formed by interlayer compounding .

[0037] The main components of the magnesite gelled flame retardant layers 2 and 4 are magnesium chloride and magnesium oxide, and the magnesite gelled flame retardant layers 2 and 4 are also filled with reinforcing materials such as sawdust or peanut shell powder and other plant fibers, glass fibers, modified agents, other mineral extracts. The wooden layers 1 and 3 are treated with flame retardant treatment.

[0038] The manufacture method of above-mentioned low-carbon novel plywood is:

[0039] a, the wood is processed into a plywood wood layer 1 and a wood layer 3 with a thickness of 7mm;

[0040] b. Press magnesium chloride, magnesium oxide, perlite, sawdust or peanut shell powder mixed gelled...

Embodiment 3

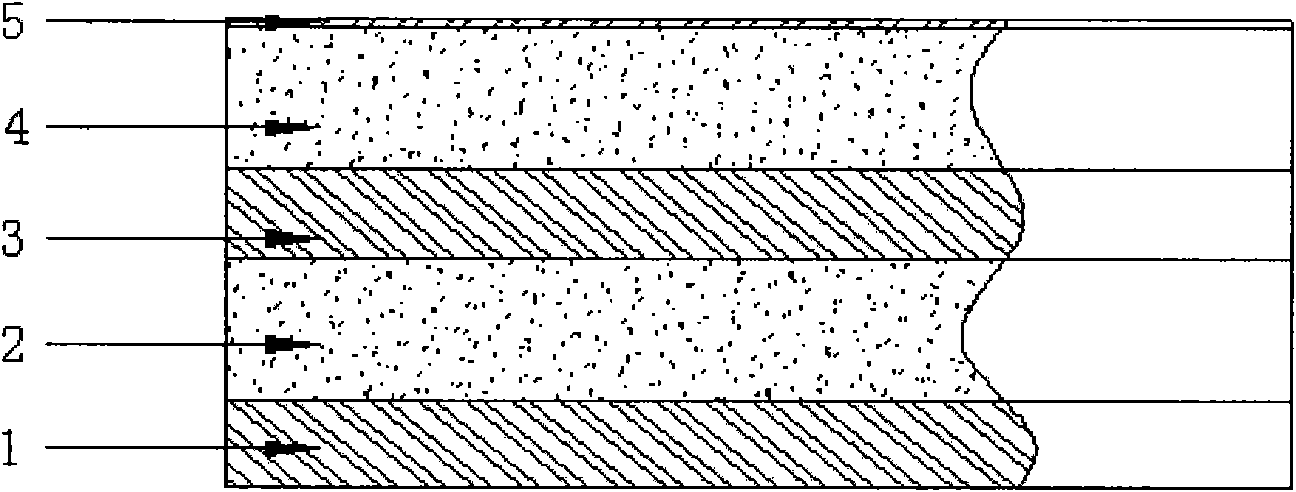

[0045] Such as image 3 As shown, a new type of low-carbon plywood, it is a five-layer structure, including decorative texture veneer 5, magnesite cemented flame-retardant layer 4, wood layer 3, magnesite cemented flame-retardant layer 2, wood Layer 1, the above-mentioned layers are composited to form a plywood.

[0046] The main components of the magnesite gelled flame retardant layers 2 and 4 are magnesium chloride and magnesium oxide, and the magnesite gelled flame retardant layers 2 and 4 are also filled with reinforcing materials such as sawdust or peanut shell powder and other plant fibers, glass fibers, modified agents, other mineral extracts. The wooden layers 1 and 3 are treated with flame retardant treatment.

[0047] The manufacture method of above-mentioned low-carbon novel plywood is:

[0048] a, the wood is processed into a plywood wood layer 1 and a wood layer 3 with a thickness of 8mm;

[0049] b. Press magnesium chloride, magnesium oxide, perlite, sawdust ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com