Ultrasonic pulse resonance jet rotary spray-head device

A technology of jet rotation and pulse jet, which is applied in the direction of injection devices, liquid injection devices, chemical instruments and methods, etc., and can solve the problems of low cleaning efficiency of single-nozzle vortex nozzles, inability to form pulsed oscillating jets, poor impact force and cleaning effect, etc. , to achieve the effects of improving striking force and cleaning efficiency, long life, and increasing cleaning width and area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

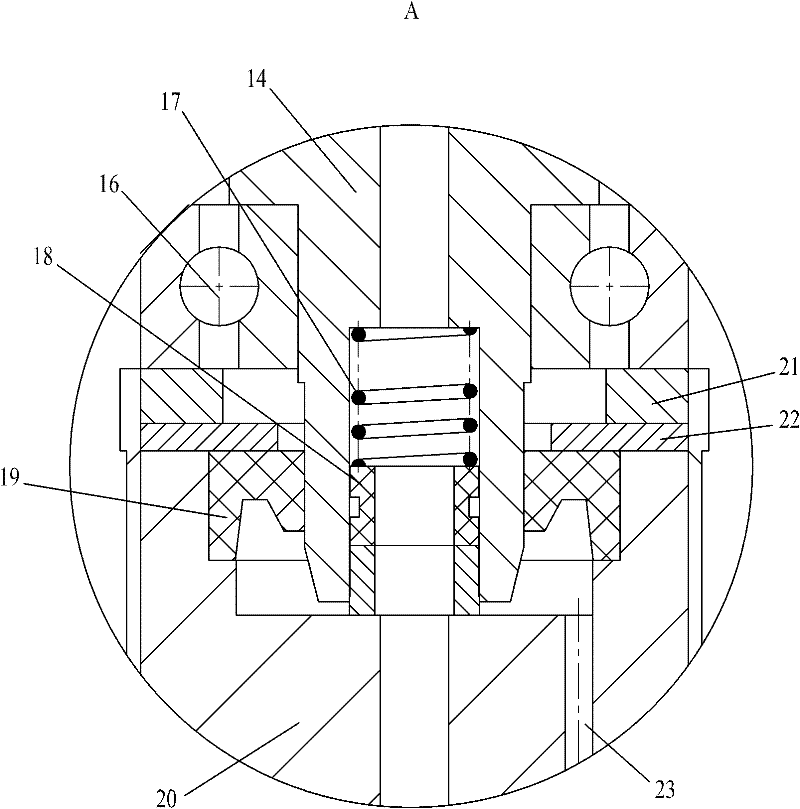

[0022] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0023] figure 1 , figure 2 Including nozzle seat 1, nozzle 2, multi-head horn 3, nozzle housing 4, oscillation chamber 5, pulse jet inlet 6, ultrasonic transducer body 7, piezoelectric ceramic sheet 8, high-pressure rotary sealing device 9, rotary Device 10, transducer shield 11, rotating brush 12, ultrasonic signal input cable 13, transducer central shaft 14, micro luffing head 15, lower bearing 16, self-tightening spring 17, sealing packing 18, oil seal 19, Rotating body 20, upper washer 21, lower washer 22, rotating body discharge hole 23, pressing device 24, upper bearing 25, high-pressure water channel 26, transducer body draining hole 27, double-ended stud 28, cavity 29, Central through hole 30, copper pad 31, etc.

[0024] Such as figure 1 As shown, the present invention is an ultrasonic pulse resonance jet rotary nozzle device, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com