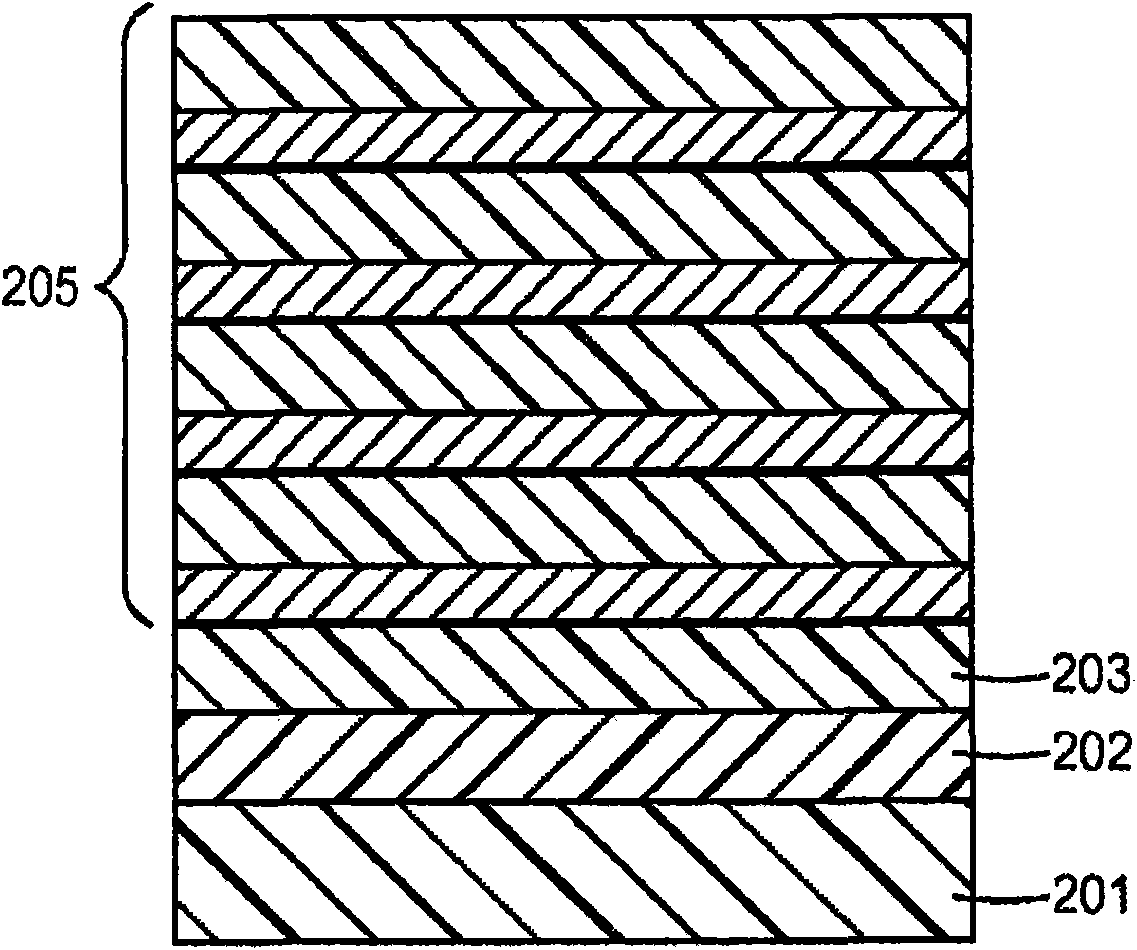

Multi-stack optical bandpass film with electro magnetic interference shielding for optical display filters

A multi-layer stacking, optical display technology, applied in the direction of filters, optics, optical components, etc., to achieve the effect of wide viewing angle and low transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0065] Optical analysis method

[0066] Measurements were performed on a Perkin Elmer Lambda 900 spectrophotometer equipped with a PELA-1000 integrating sphere attachment. The integrating sphere has a diameter of 150 mm (6 inches) and complies with ASTM methods E903, D1003, E308, etc., published in the third edition of "ASTM Standards on Color and Appearance Measurement," published by ASTM in 1991. The total light transmittance (TLT) of the sample is measured at the position on the front side of the sample, and the total light reflectance (TLR) of the sample is measured at the position on the back side of the sample. The incidence angles are normal (0°) and 70° for TLT and near normal (10°) and 70° for TLR. Measure front surface reflectance. Some of these samples were mounted on a 60mm x 80mm aluminum frame about 1mm thick to support them. Each frame has an fenestration measuring 50mm x 33mm. The membranes were adhered to these frames (bonded to the front of the membrane...

example 2 and 3

[0067] For Examples 2 and 3, near-normal TLR was measured with additional sample treatment to remove back surface reflections by grinding the back of the mounted film with 50 μm alumina powder in a shot peening cylinder and then spraying with black textured paint.

[0068] EMI shielding analysis method

[0069] All measurements were performed with an HP 8510 Vector Network Analyzer (HP 8510 Vector Network Analyzer from Hewlett Packard (Palo Alto, CA)) through a coaxial transmission cell (TEM cell), using a 10% span smoothing window, and all measurements complied with ASTM Method D4935. Results are reported in decibels (dB). Surface resistance was measured according to the eddy current method using a Model 717B Benchtop Conductance Monitor (available from Delcom Instruments Inc. (Prescott, WI.)).

[0070] Transmission Electron Microscopy (TEM) Analysis Method

[0071] TEM samples were prepared by room temperature ultrathin sectioning technique. Film samples were embedde...

example 1

[0079] The substrate was TETORON XB-3 from DuPont Teijin Films. Using the manufacturing method described above, the operating conditions are listed in Table 1. Example 1 is a stacked optical filter with 4 dyads.

[0080] Table 1

[0081] Operating conditions of instance 1

[0082] frequency

Line speed

(m / min)

Plasma treatment (kW)

Seed Layer / Conductive Layer

polymer layer

1

18

Ti(N 2 )1kW

none

PTEA mixture

(1.36cm 3 / min, 91nm)

2

Rewind

none

none

none

3

18

Ti(N 2 )1kW

ZnO x (4kW) / silver (8kW,

15nm)

PTEA mixture

(1.10cm 3 / min, 71nm)

4

Rewind

none

none

none

5

18

Ti(N 2 )1kW

ZnO x (4kW) / Silver (8kW,

15nm)

PTEA mixture

(0.95cm 3 / min, 63nm)

6

Rewind

none

none

none

7

18

Ti(N 2 )1kW

ZnO x (4kW) / s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com