Device with direct control, in particular proportional and/or rectilinear control, for fluid loading and/or unloading system

A loading system and control device technology, applied in control/regulation systems, general control systems, liquid distribution, transportation or transfer devices, etc., can solve the problem of increasing obstacles or the danger of target pipelines, making it difficult for operators to connect pipes, and damage pipes Joint sealing and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

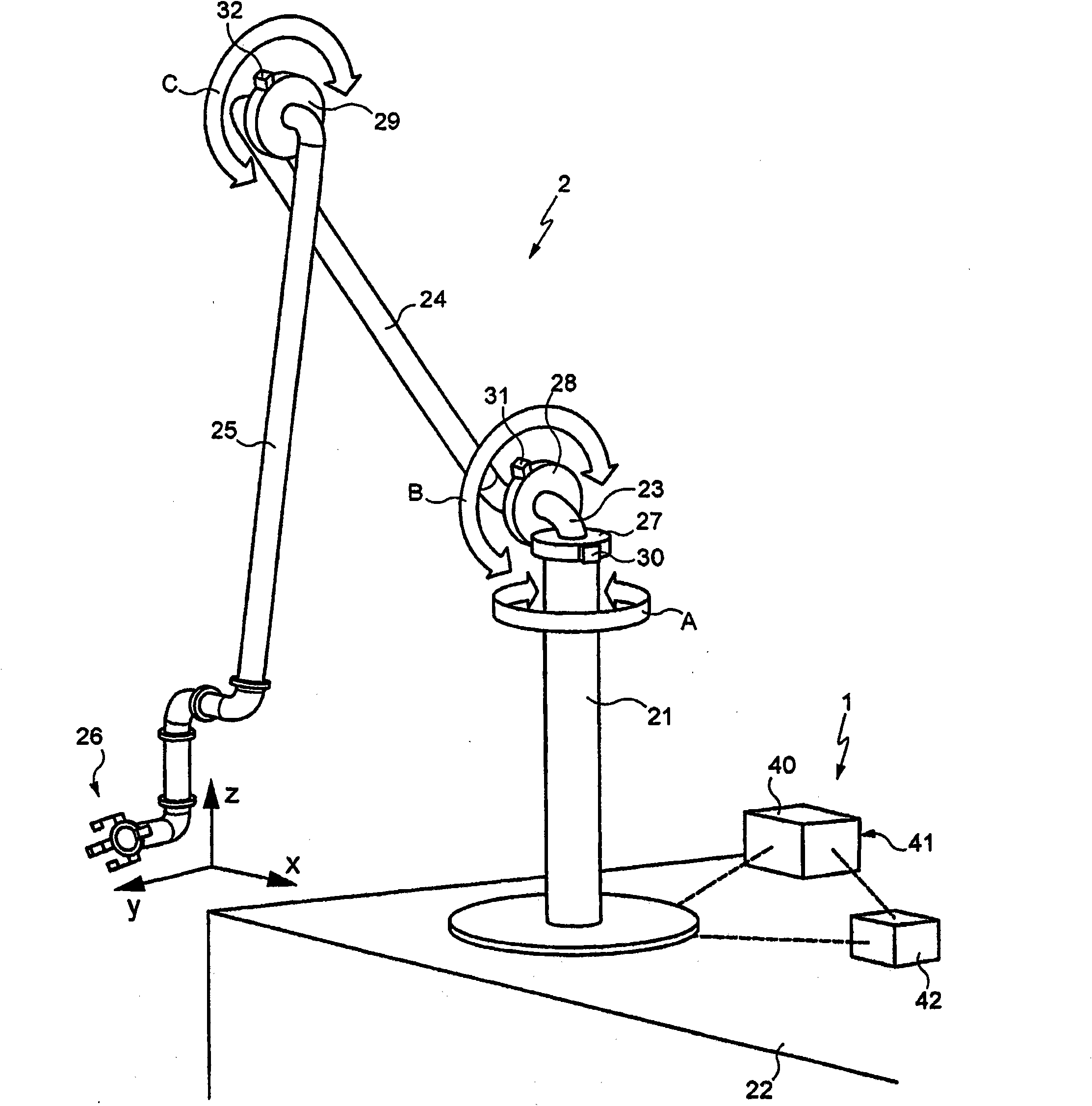

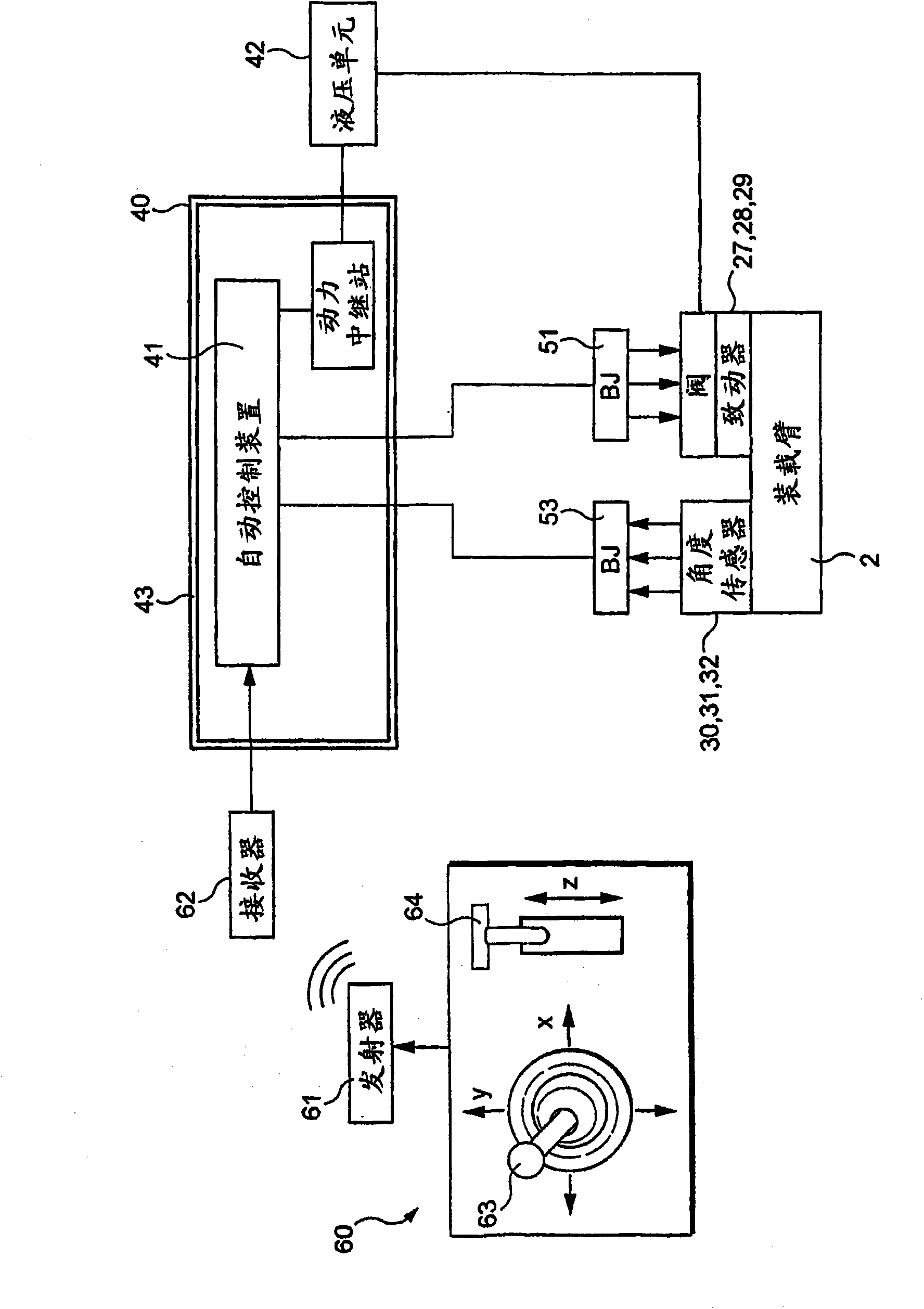

[0037] figure 1 A loading arm 2 equipped with a control device 1 according to the invention is shown very schematically. Here the loading arm is shown very simplified and it should be pointed out that the control device according to the invention can be used in any type of marine loading system, in particular the system described above.

[0038] figure 1 The loading arm has a base 21 connected to a fluid tank located below a surface 22 on which the base is fixed and which may be, for example, a dock or the deck of a ship. An elbow 23 is pivotally hinged at the top end of the base to which is hinged a first tube, also called inner tube 24 , whose opposite end is hinged to a second tube, called outer tube 25 . The outer tube ends with a nipple 26 suitable for connection to a target pipeline (not shown), for example on a ship. In a known manner, the pipe connection has three rotational degrees of freedom relative to the end of the outer pipe. These three rotations are free, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com