Manufacture method of memory metal sheet of circuit breaker for vehicle

A manufacturing method and metal sheet technology, which can be used in circuits, metal processing equipment, electrical switches, etc., and can solve problems such as misjudgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 0

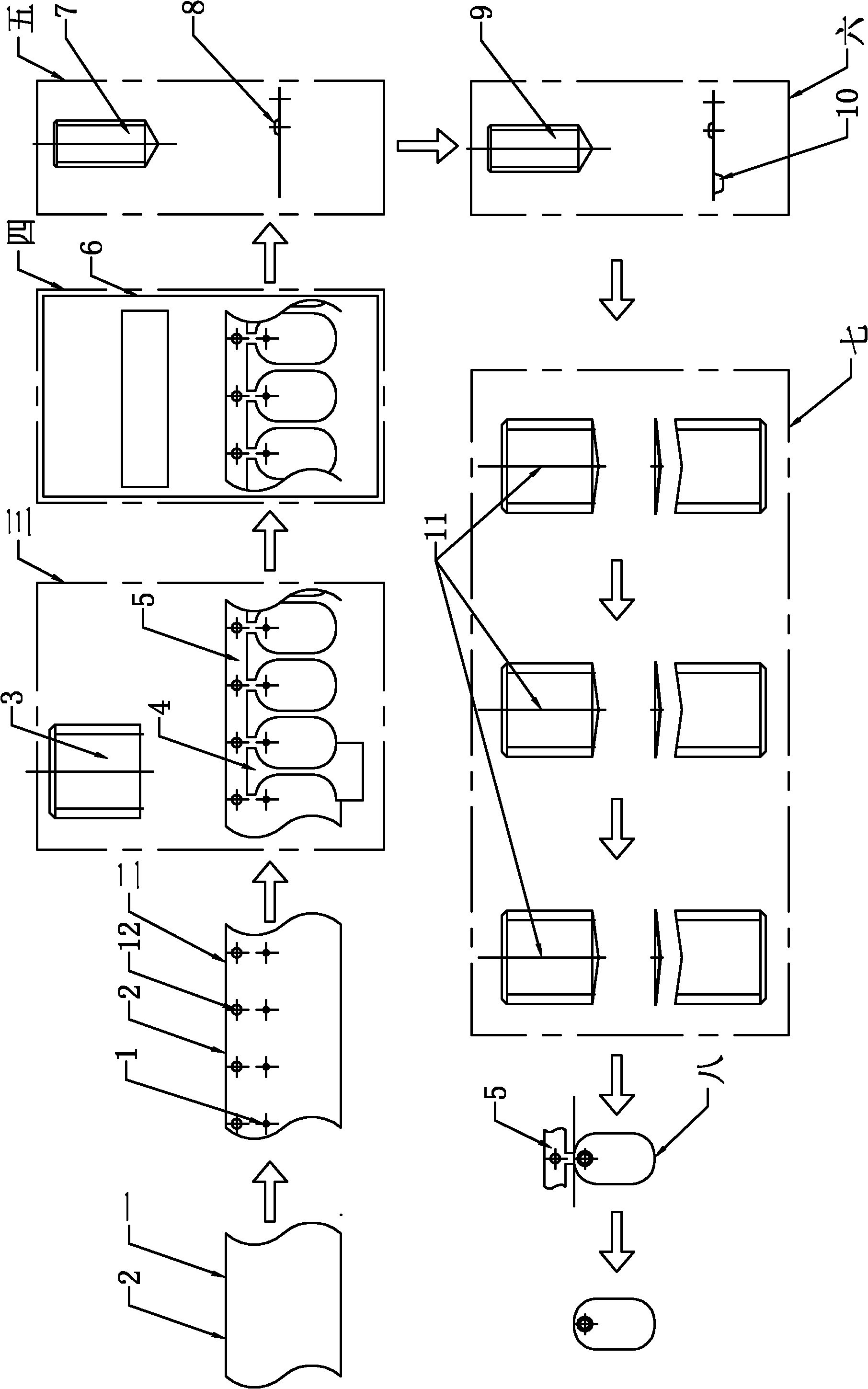

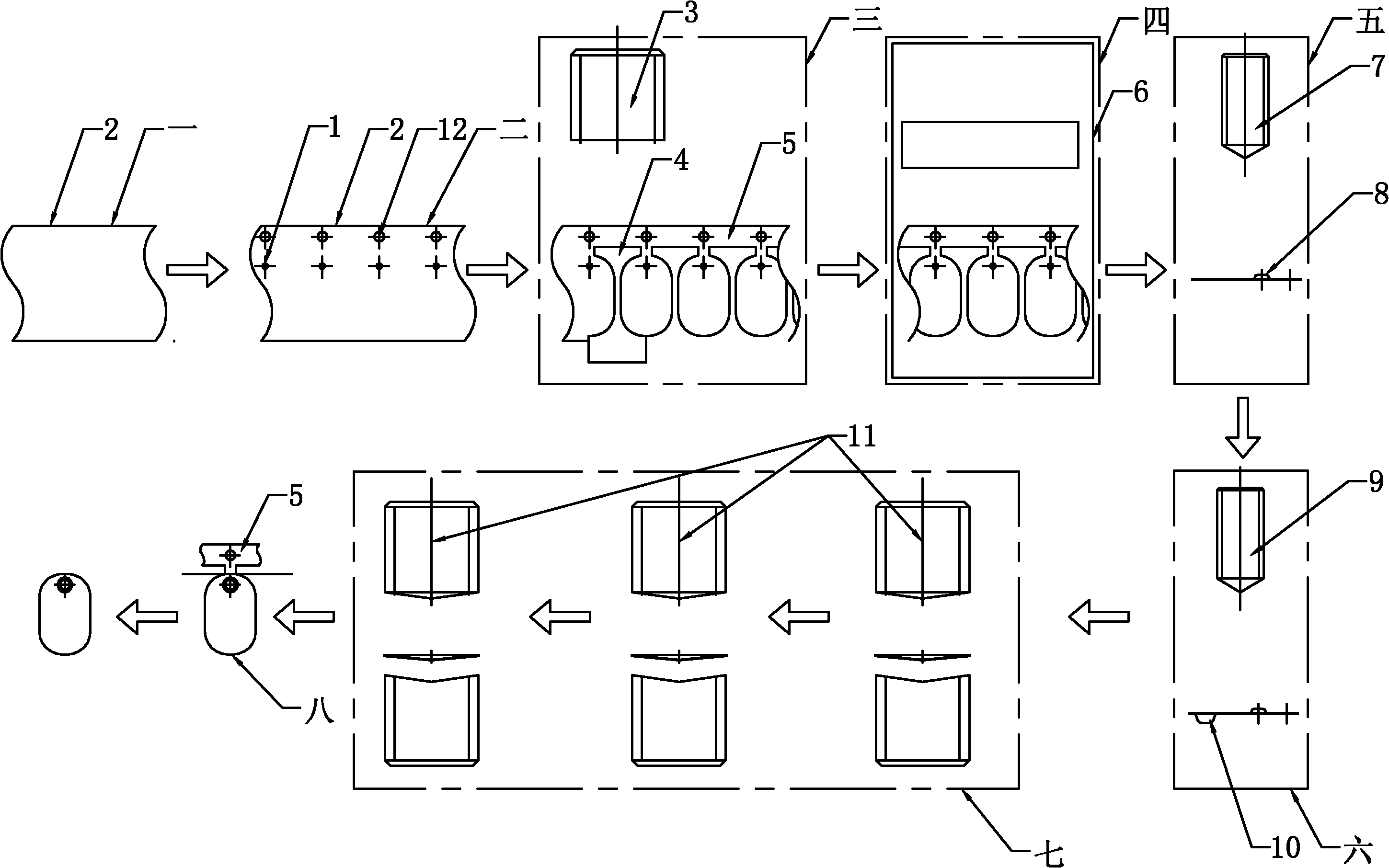

[0015] DETAILED DESCRIPTION Zero: Combining figure 1 Describe this embodiment, the steps of this embodiment are as follows:

[0016] Step 1: Preheating, heating the strip-shaped memory alloy 2 to 20-40°C through a heater, and keeping the temperature to enter the next process;

[0017] Step 2: Punching holes, using a punching machine combined with a round hole mold to punch out round holes 1 at equal intervals along the length of the strip-shaped memory alloy 2, and the diameter of the round holes 1 is 1mm;

[0018] Step 3: Blanking, use the pneumatic press 3 in combination with the I-shaped stamping die 4 to punch the strip-shaped memory alloy 2 into a rectangular metal sheet with rounded corners, the length of the rectangular metal sheet with rounded corners is 16 mm, The width is 9.5mm and the fillet radius is 4.75mm. The round hole 1 punched in step 2 is located on the rectangular metal sheet with rounded corners, and is located on the center line of the rectangular metal ...

specific Embodiment approach 1

[0024] Specific implementation mode one: combine figure 1 Describe this embodiment, the difference between this embodiment and specific embodiment 1 is that in the process of punching in step 2, a punching machine is used to punch out the round hole 1 and at the same time a guide hole 12 is punched out, and the center of the round hole 1 after punching is The center of the guide hole 12 is located on the same straight line, the straight line is perpendicular to the side of the length direction of the strip-shaped memory alloy 2 , and the guide hole 12 is located on the connecting side 5 . Other steps are the same as in the first embodiment. The guide holes 12 are used for dragging by the puller according to the direction in which the guide holes 12 are arranged in sequence and the interval length of the guide holes 12 in the process from step 3 to step 8.

specific Embodiment approach 2

[0025] Embodiment 2: This embodiment differs from Embodiment 1 or Embodiment 3 in that the strip-shaped memory alloy 2 is formed by mixing or superimposing at least two metals with different thermal expansion coefficients. Other steps are the same as those in Embodiment 1 or 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com