Vehicular harness on-off detection equipment

A technology of on-off detection and equipment, applied in the direction of measuring electricity, measuring devices, measuring electrical variables, etc., can solve the problems of missed detection, error-prone, substandard products, etc., to improve the detection efficiency, reduce the error rate, and speed up the detection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

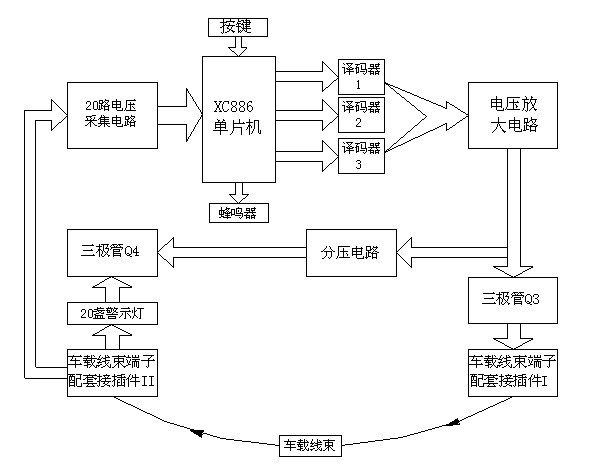

[0020] 1. Hardware implementation

[0021] figure 1 It is the circuit block diagram of the on-off detection equipment of the vehicle wiring harness, as shown in the figure. The on-off detection equipment of the vehicle wiring harness includes a single-chip microcomputer, a buzzer, a decoder, a voltage amplifier circuit, a 20-way switch circuit, a 20-way voltage divider circuit, a 20-way voltage acquisition circuit, 20 light-emitting diodes (that is, indicator lights) and for control The single-chip microcomputer receives the button for inquiring the on-off command of the wiring harness.

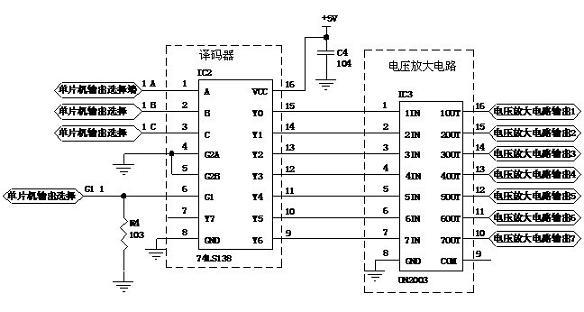

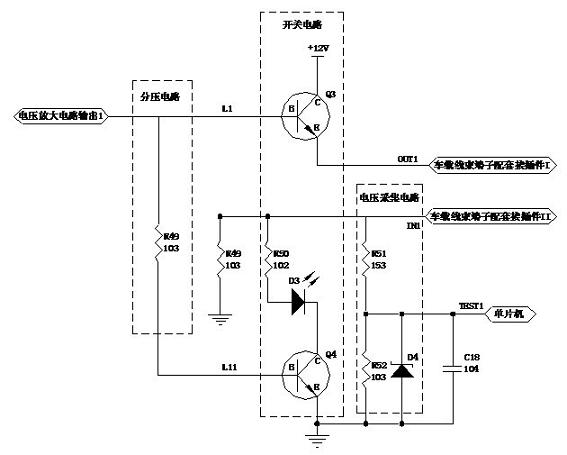

[0022] The buzzer is connected to the single-chip computer; the signal output terminal of the single-chip computer is connected with the decoder; the signal output terminal of the decoder is connected with the input terminal of the voltage amplif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com