Simple and convenient method for preparing super-hydrophobic film on surface of metal matrix

A metal matrix, super-hydrophobic technology, used in surface reaction electrolytic coatings, electrolytic coatings, coatings, etc., can solve the problem of long processing time, achieve the effect of simple operation and shorten the film forming time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] 1) Substrate cleaning: Clean the surface of the copper substrate with ethanol and deionized water successively, and dry it with nitrogen gas for later use;

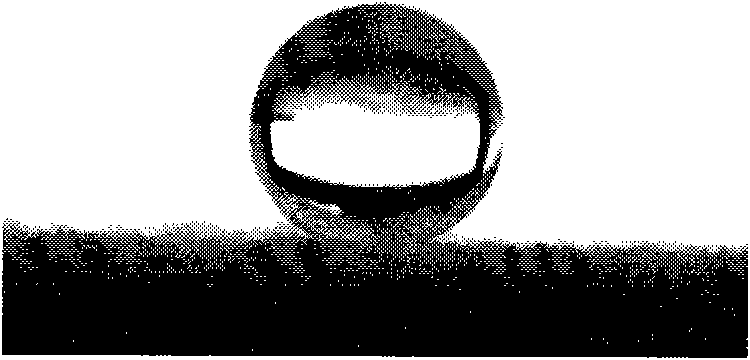

[0016] 2) Preparation of superhydrophobic membrane: using electrochemical method, 0.5mol / LCH at 25°C 3 (CH 2 ) 12 In the ethanol solution of COOH, a 10V DC voltage was applied between the cleaned copper substrate and the platinum electrode as the cathode. After 1 hour of treatment, a blue fatty acid-copper complex film appeared on the copper surface, and after drying with nitrogen, the film took the form of Superhydrophobic state, the surface contact angle is 151.3 ± 3 ° (see figure 1 ).

Embodiment 2

[0018] 1) Substrate cleaning: Clean the surface of brass (28wt.% Zn, 72wt.% Cu) with ethanol and deionized water in sequence, and dry it with nitrogen gas for later use;

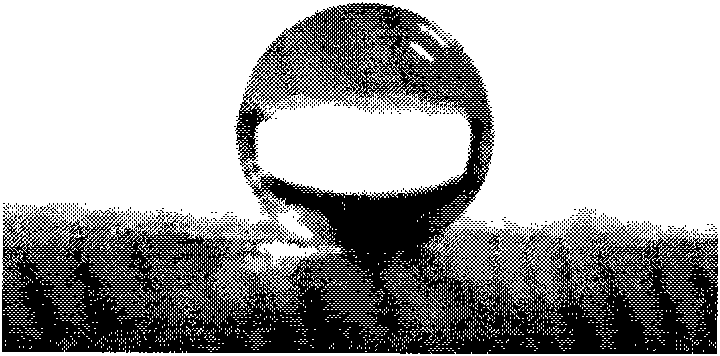

[0019] 2) Preparation of superhydrophobic membrane: using electrochemical method, 0.3mol / LCH at 25°C 3 (CH 2 ) 12 In the ethanol solution of COOH, a 40V DC voltage was applied between the cleaned brass substrate and the platinum electrode as the cathode. After 2 hours of treatment, a light blue fatty acid-metal complex film appeared on the surface of the brass. After drying with nitrogen, the film The layer is in a superhydrophobic state, and the surface contact angle is 154.7±3° (see figure 2 ).

Embodiment 3

[0021] 1) Substrate cleaning: Clean the surface of the zinc substrate with ethanol and deionized water in sequence, and dry it with nitrogen gas for later use;

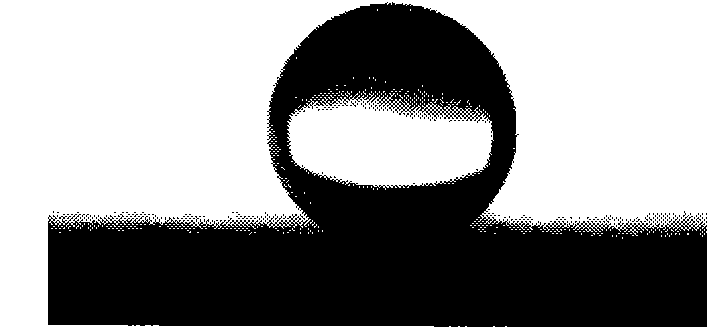

[0022] 2) Preparation of superhydrophobic membrane: using electrochemical method, 0.1mol / LCH at 25°C 3 (CH 2 ) 12 In the ethanol solution of COOH, a 30V DC voltage was applied between the cleaned zinc substrate and the platinum electrode as the cathode. After 2 hours of treatment, a white fatty acid-zinc complex film layer appeared on the zinc surface. Hydrophobic state, the surface contact angle is 152.5±3° (see image 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com