Preparing method of sulfonated fatty acid phosphate rock reverse flotation collecting agent

A sulfonated fatty acid, reverse flotation technology, applied in flotation, solid separation and other directions, can solve the problems of poor low temperature resistance, poor water solubility, poor selectivity, etc., to enhance low temperature resistance, good flotation effect, improve The effect of production indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

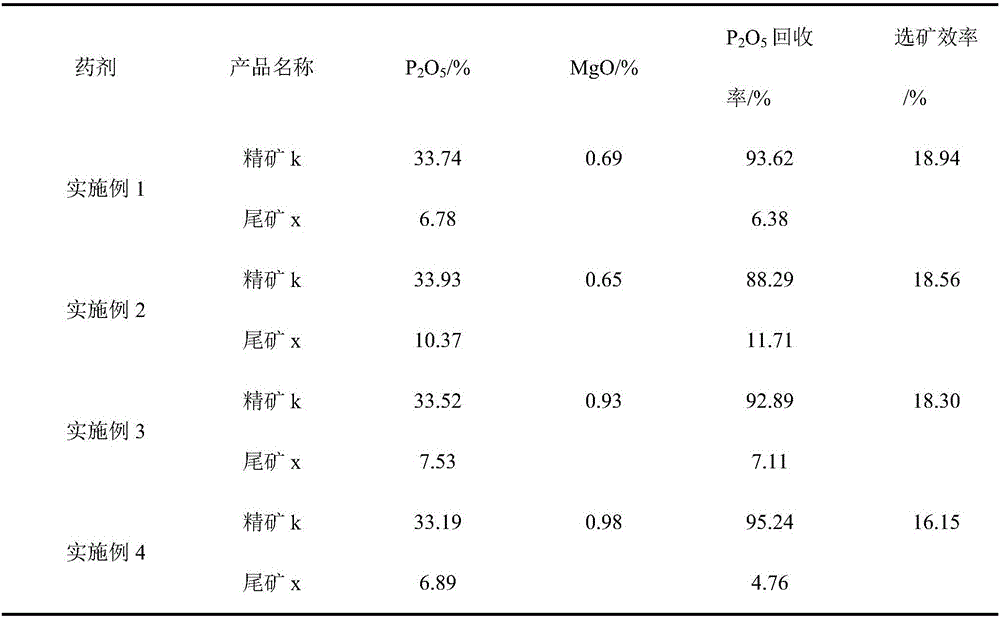

Embodiment 1

[0021] According to the mass ratio of palmitic acid and stearic acid of 0.3:1, the mixed higher fatty acid is prepared for use. Take 286g of mixed higher fatty acid and place it in a 1L three-necked flask, and melt it at 90°C. 29.18 g of concentrated sulfuric acid (mass concentration: 98%) was slowly added dropwise into the three-necked flask through a constant pressure titration funnel, and the reaction temperature was adjusted to 80° C. for 3 h. After the reaction was completed, hot water was added into the three-necked flask and stirred for 0.5 h, followed by washing with hot water to neutrality and then standing for separation to obtain the product α-sulfonated fatty acid. Prepare 200g of sodium hydroxide into a 10wt% sodium hydroxide solution, add it together with 300g of α-sulfonated fatty acid and 150g of lauric acid into an autoclave, adjust the reaction temperature to 140°C and stir for 2 hours to obtain the basic substance. Water is added to the basic material to pr...

Embodiment 2

[0023] According to the mass ratio of palmitic acid and stearic acid of 0.4:1, the mixed higher fatty acid is prepared for use. Take 286g of mixed higher fatty acid and place it in a 1L three-necked flask, and melt it at 90°C. Slowly drop 116.73 g of concentrated sulfuric acid into a three-necked flask through a constant pressure titration funnel, and adjust the reaction temperature to 80° C. for 5 h. After the reaction was completed, hot water was added into the three-necked flask and stirred for 0.5 h, followed by washing with hot water to neutrality and then standing for separation to obtain the product α-sulfonated fatty acid. Prepare 300g of sodium hydroxide into a 15wt% sodium hydroxide solution, add it together with 600g of α-sulfonated fatty acid and 400g of palmitic acid into an autoclave, adjust the reaction temperature to 150°C and stir for 3 hours to obtain the basic substance. Water is added to the basic material to prepare a solution with a solid content of 2 wt...

Embodiment 3

[0025] The mixed higher fatty acid is prepared according to the mass ratio of palmitic acid and stearic acid of 0.5:1 for later use. Take 286g of mixed higher fatty acid and place it in a 1L three-necked flask, and melt it at 90°C. Slowly drop 175.10 g of concentrated sulfuric acid into a three-necked flask through a constant pressure titration funnel, and adjust the reaction temperature to 80° C. for 6 h. After the reaction was completed, hot water was added into the three-necked flask and stirred for 0.5 h, followed by washing with hot water to neutrality and then standing for separation to obtain the product α-sulfonated fatty acid. Prepare 100g of sodium hydroxide into a 20wt% sodium hydroxide solution, add it together with 300g of α-sulfonated fatty acid and 200g of stearic acid into an autoclave, adjust the reaction temperature to 160°C and stir for 4 hours to obtain the basic substance. Water is added to the basic material to prepare a solution with a solid content of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com