Method for manufacturing low-cost super-high intensity steel plate with yield strength of over 960 MPa for wide process operation window

A technology of yield strength and operating window, applied in the manufacturing field of ultra-high strength steel plate and its laboratory, can solve the problems of complex process, tensile strength can only reach 890MPa or more, and the task of deoxidation of molten steel is heavy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

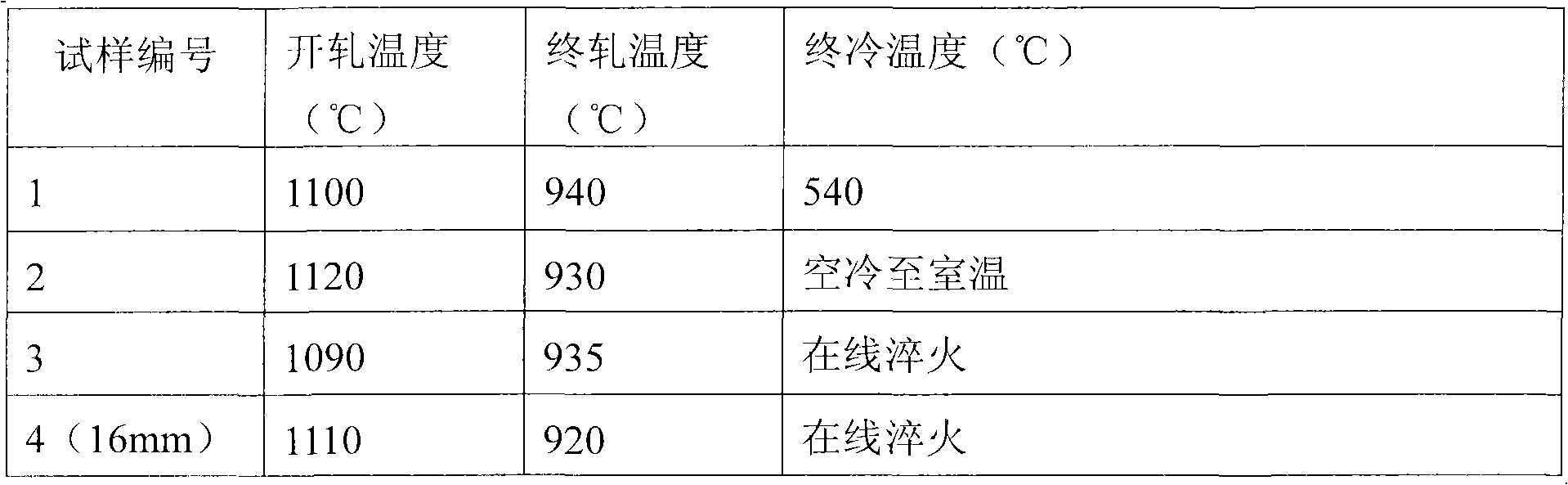

[0058] Table 5 embodiment 1TMCP rolling process parameter

[0059]

[0060]

Embodiment 2

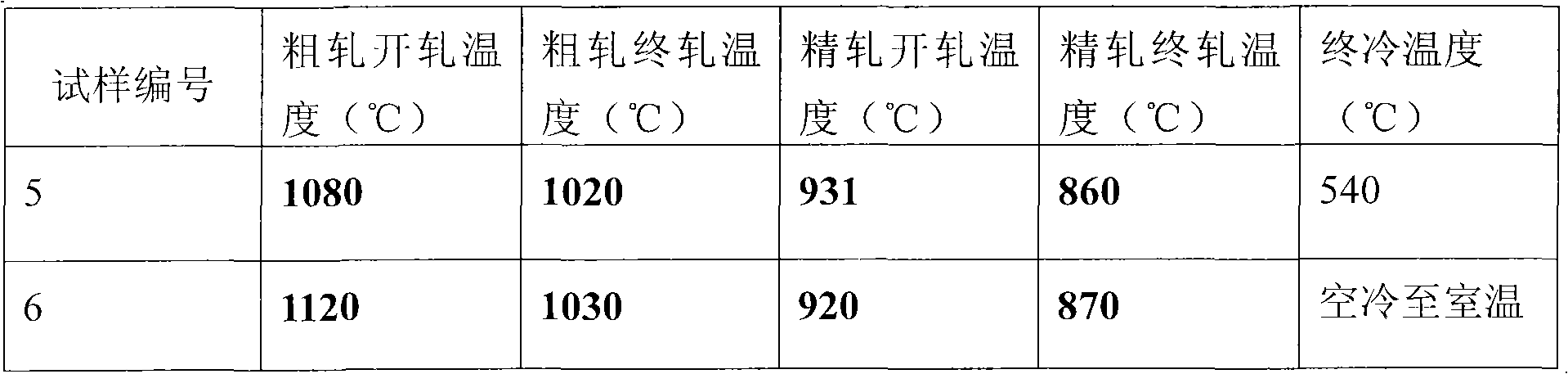

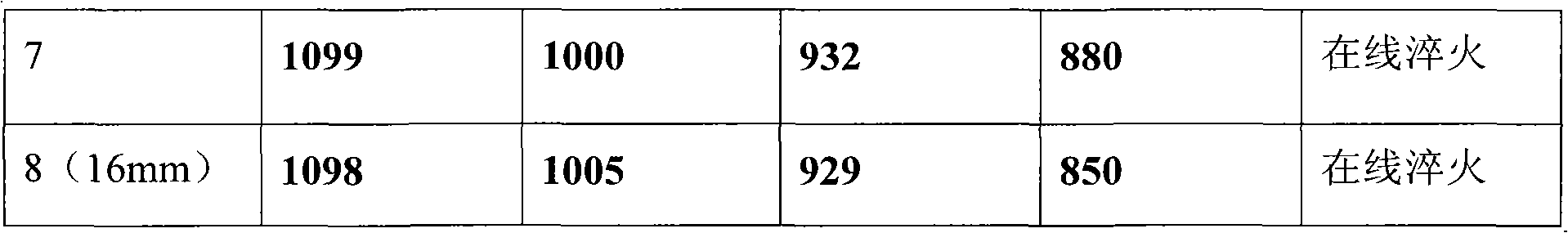

[0061] Table 6 embodiment 2TMCP rolling process parameters

[0062]

[0063] Table 7 The conventional mechanical properties of the steel plate in Example 1 after heat treatment

[0064]

[0065]

[0066]Note: In the type column, the meaning of the number is explained with "1-180-2" as an example, "1" represents the number of the hot-rolled substrate; "180" represents the tempering temperature; "2" represents the No. Two parallel samples. Except for samples 3, 4, 7, and 8, which are quenched online, the rest are quenched offline. The off-line quenching temperature is 920°C, and the holding time is 40 minutes. The holding time for low-temperature tempering (tempering temperature ≤ 210°C) is 120-150 minutes, and the holding time for high-temperature tempering (tempering temperature 550°C) is 40 minutes.

[0067] Table 8 Example 2 Conventional mechanical properties of the steel plate after heat treatment

[0068]

[0069] Note: In the type column, the meaning of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com