Modified recovered cutting fluid

A cutting fluid and modification technology, applied in the direction of lubricating compositions, etc., can solve the problems of ineffective control of fouling, bad impurities are not removed, and the recovery quality is not very good, so as to achieve reuse and reduce surface damage. Occurrence rate, the effect of reducing cutting costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

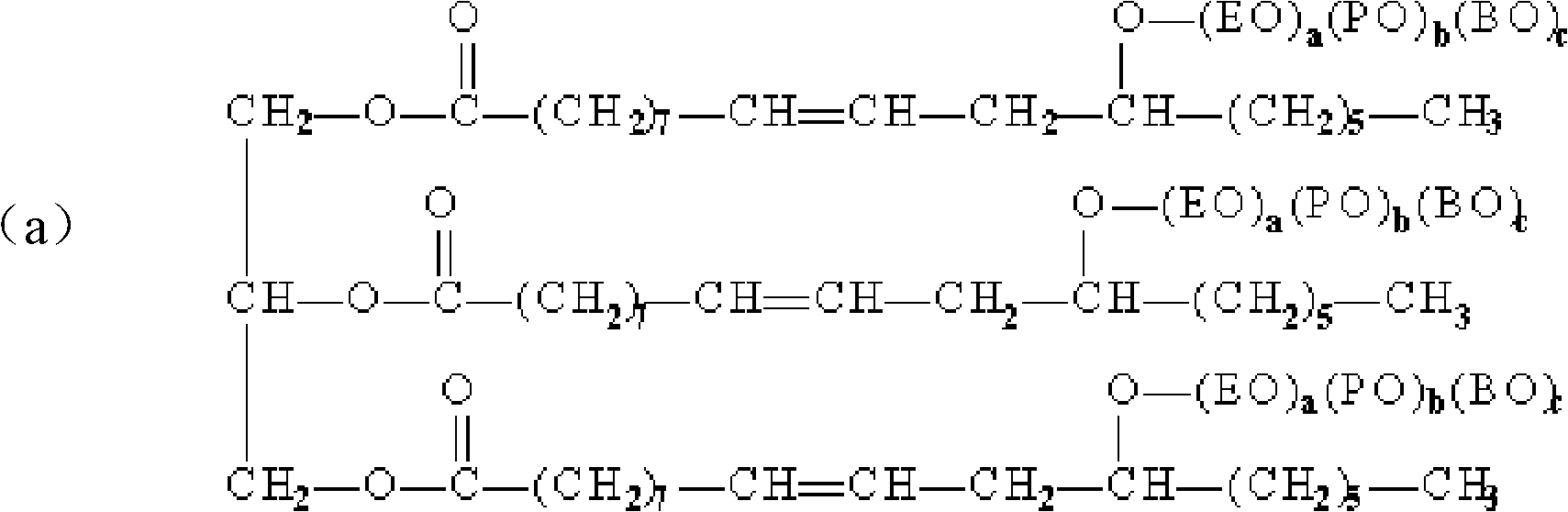

Method used

Image

Examples

Embodiment 1

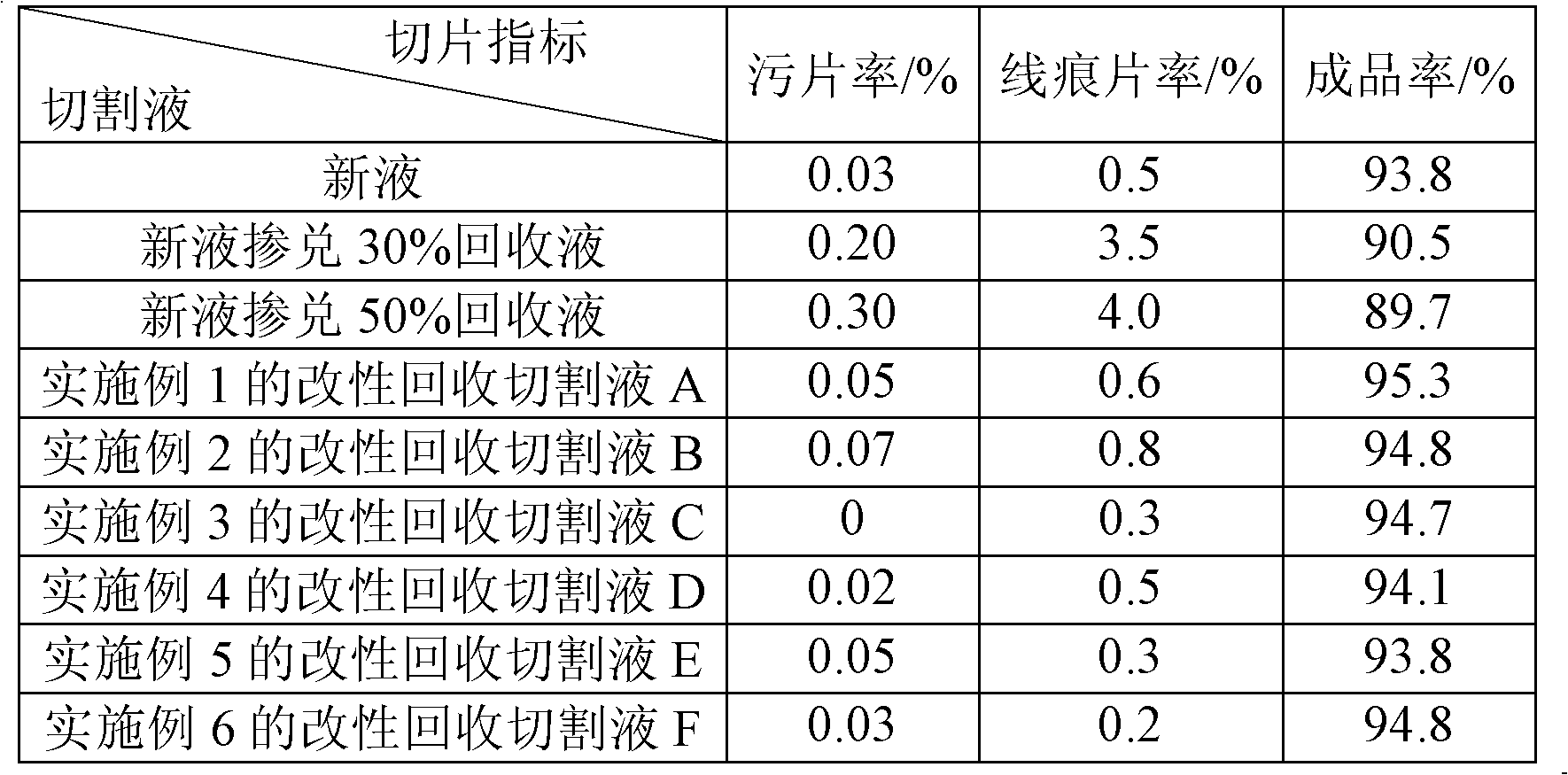

[0041] Under normal temperature and pressure, prepare 5 tons of modified recovered cutting fluid: take recovered cutting fluid 4995kg, AEO 9 2.5kg of phosphoric acid ester and 2.5kg of 2,2',2"-nitrotriethyl titanate triethylene glycol were mixed and stirred evenly to obtain a colorless and transparent liquid, which was the modified recovered cutting fluid A. The cutting fluid used See Table 1 for cutting application data.

Embodiment 2

[0043] Under normal temperature and pressure, prepare 5 tons of modified recovery cutting fluid: take recovery fluid 4997kg, bis(dioctyloxypyrophosphate) ethylene titanate and triethanolamine chelate 3kg, AEO 3 Mix and stir 25g of phosphate ester and NP-825g evenly to obtain a colorless transparent liquid which is the modified recovered cutting fluid B. See Table 1 for cutting application data using this cutting fluid.

Embodiment 3

[0045] Under normal temperature and pressure, prepare 5 tons of modified recovered cutting fluid: take 4970 kg of recovered fluid, 25 kg of castor oil polyoxyethylene ether (commercially available EL-10), and 5 kg of LN-8, mix and stir evenly to obtain a colorless transparent liquid that is It is the modified recovered cutting fluid C. See Table 1 for cutting application data using this cutting fluid.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com