Photocurable composition for embossing and method for producing cured products

A curable composition, molding technology, applied in photosensitive materials for opto-mechanical equipment, photolithographic process exposure devices, optics, etc., can solve the problem of insufficient adhesion, unsuitable optical materials, unsuitable optical materials problem, to achieve the effect of excellent optical lens

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment A

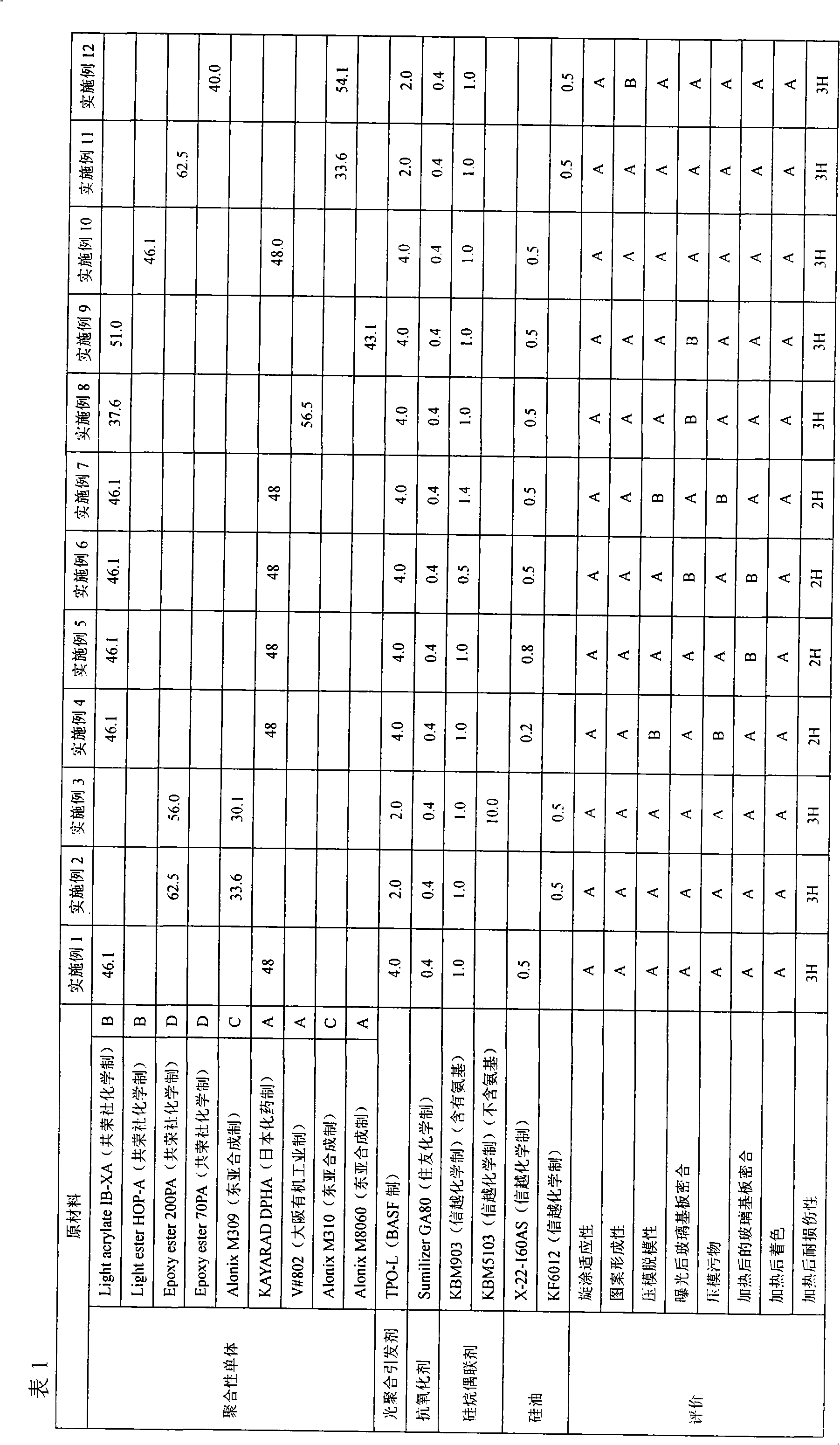

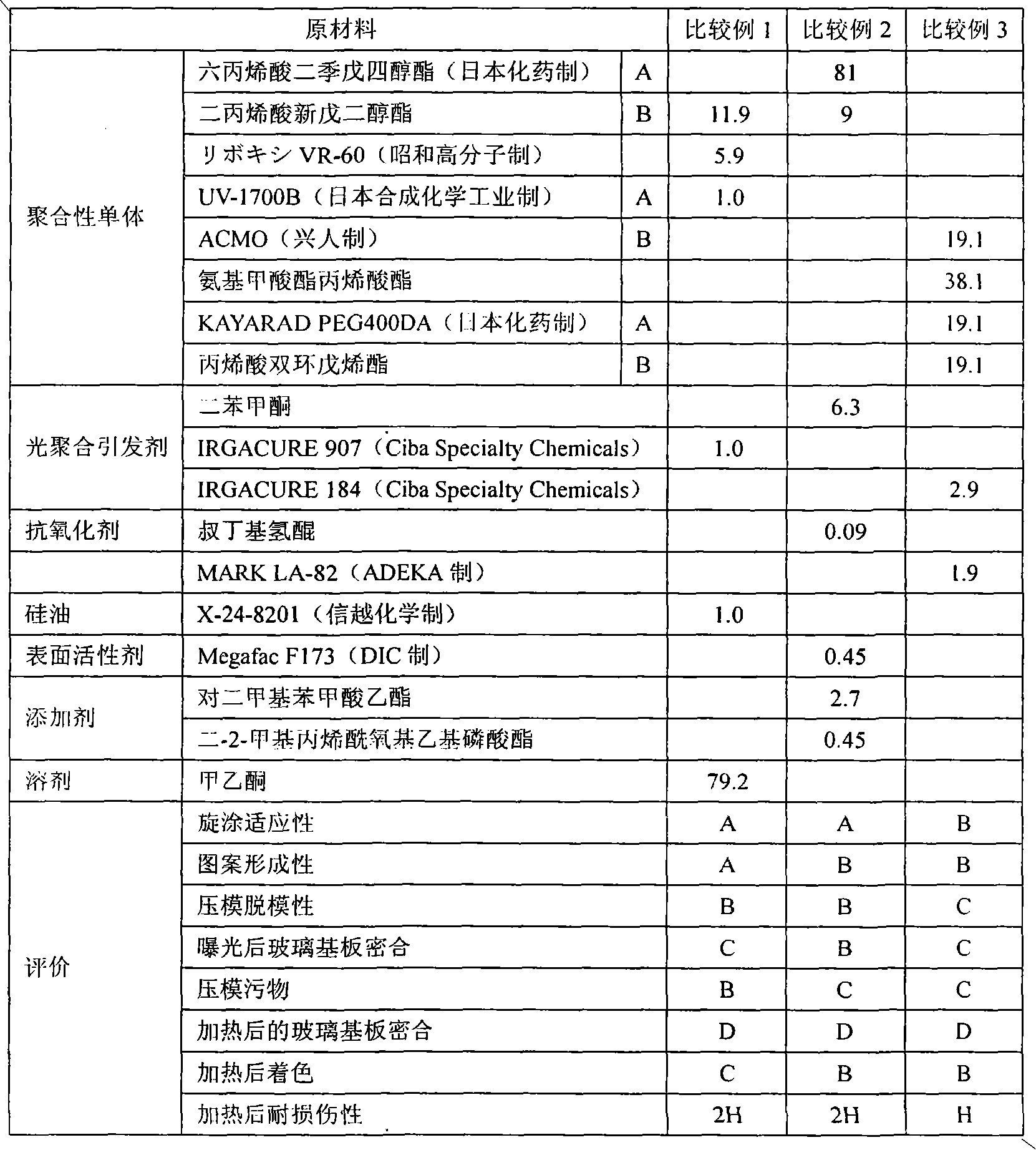

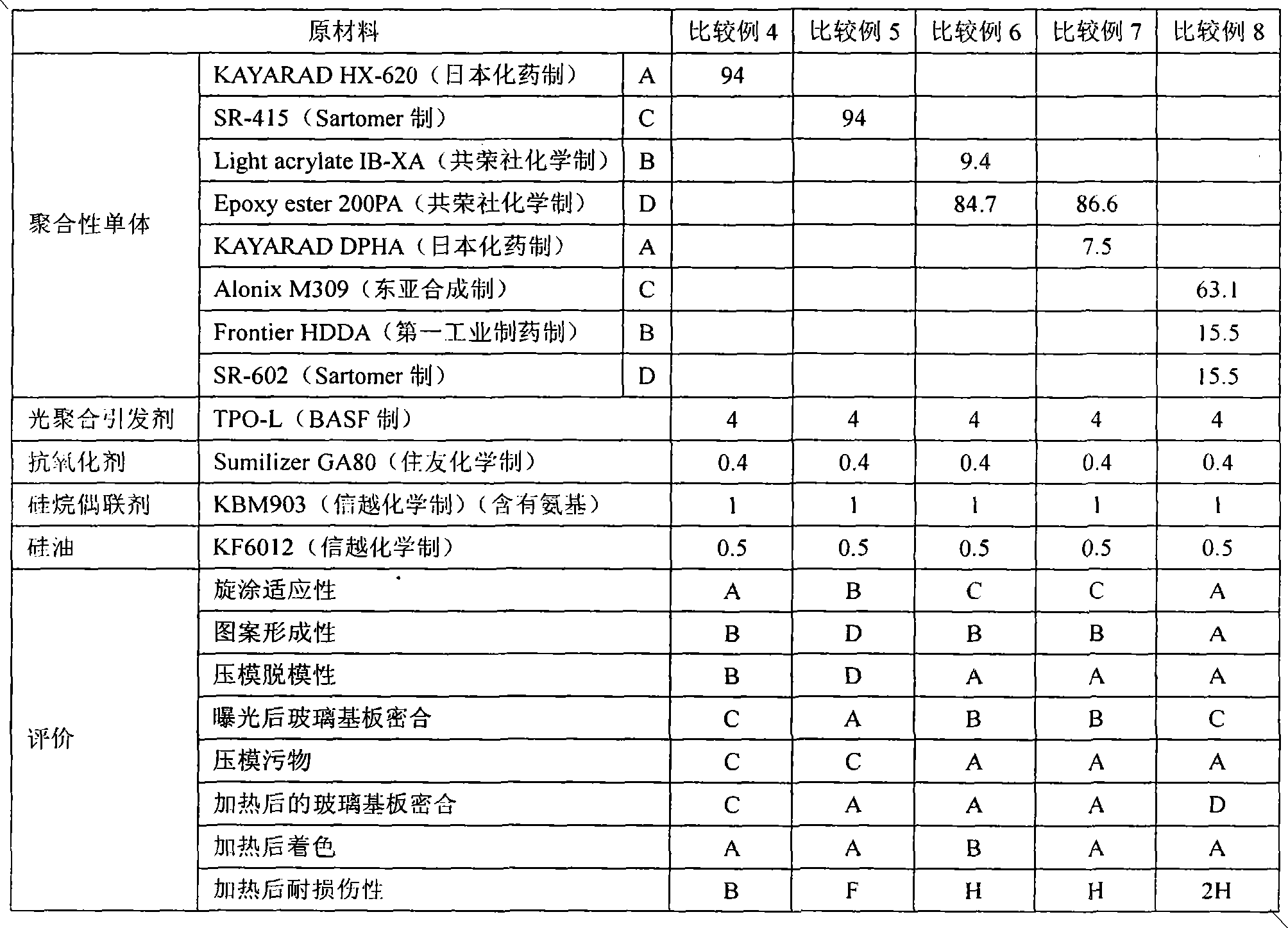

[0143] The polymerizable monomers, photopolymerization initiators, antioxidants, silane coupling agents and silicone oils shown in the following Tables 1 to 3, and other components added as needed were blended to prepare a composition. In Tables 1 to 3, the content of each component is expressed in% by weight.

[0144] The composition obtained above was subjected to the following tests and evaluated. The results are shown in Tables 1 to 3. The viscosities of Examples 1 to 12 and Comparative Examples 4 to 7 were in the range of 90 to 1000 mPa·s. In addition, the viscosities of Comparative Examples 1 to 3 and 8 are outside the range of 90 to 1000 mPa·s.

[0145]

[0146] The viscosity measurement was performed at 25±0.2°C using an RE-80L rotational viscometer manufactured by Toki Sangyo Co., Ltd. Regarding the rotation speed during the measurement, when the viscosity is 0.5 mPa·s or more and less than 5 mPa·s, the rotation speed is 100 rpm; when the viscosity is 5 mPa·s or more an...

Embodiment B

[0206] In Examples 1, 2, 4 to 12 of Example A, the silane coupling agent and the silicone oil were not added, and the others were carried out in the same manner. The results show that although the obtained composition is at a practical level, it has coating suitability, mold release properties, glass substrate adhesion after exposure, mold stains, glass substrate adhesion after heating, and damage resistance after heating Any one or more of the properties tends to deteriorate slightly.

[0207] In Examples 1, 2, 4 to 12 of Example A above, a silane coupling agent (KBM903, manufactured by Shin-Etsu Chemical) was used instead of the amino-free silane coupling agent (KBM5193, manufactured by Shin-Etsu Chemical), and the others were the same get on. As a result, it can be seen that although the obtained composition is at a practical level, it slightly deteriorates in any one or more of mold release properties, glass substrate adhesion after exposure, mold dirt, and glass substrate a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com