An Improved Air Packing Device

An air-packing and air-inlet technology, applied in the directions of transportation and packaging, packaging of vulnerable items, types of items to be packaged, etc., can solve problems such as increased packaging costs, excessive packaging, tearing, etc., to increase safety and resist falling. Protective performance, and the effect of cushioning protective performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

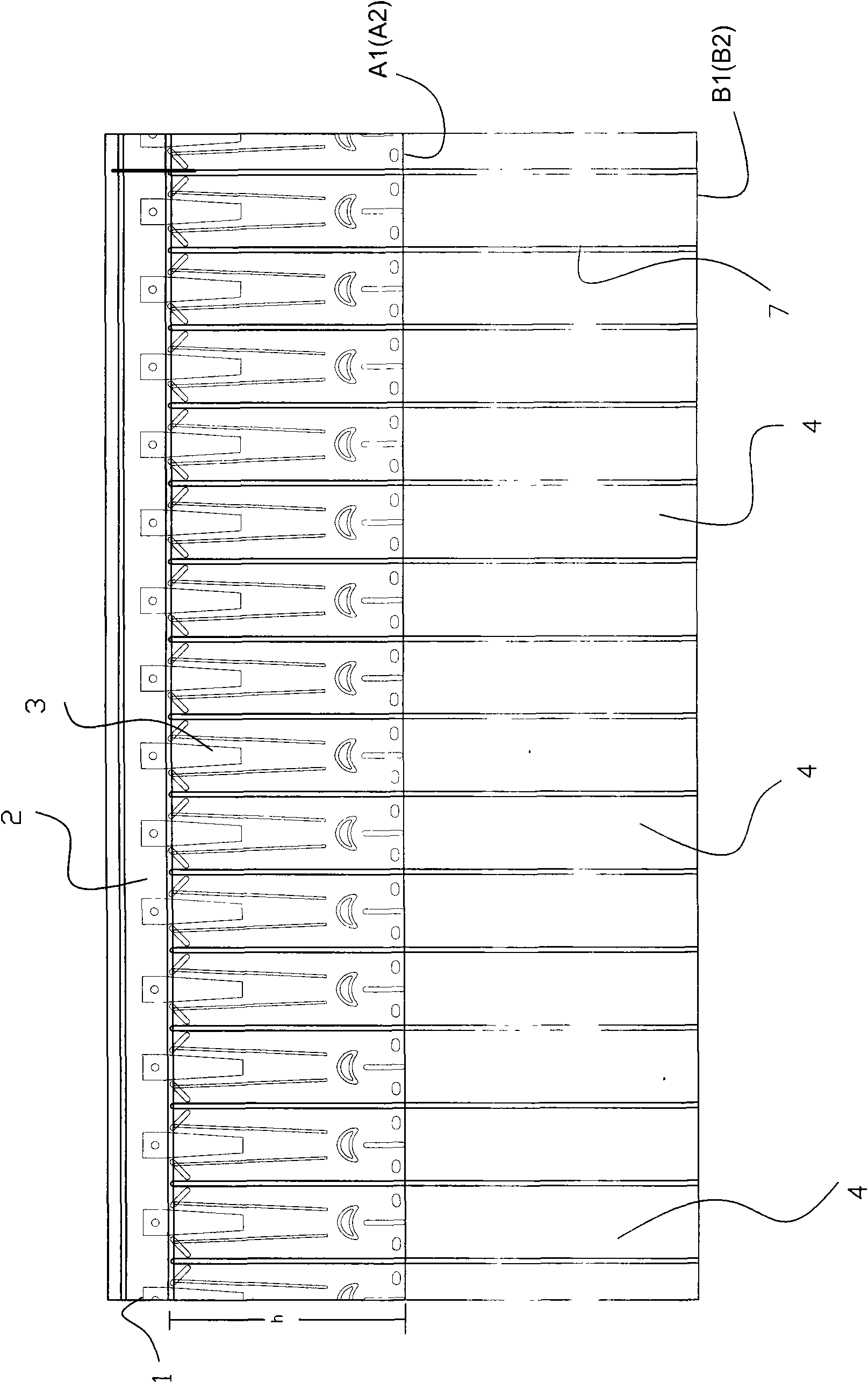

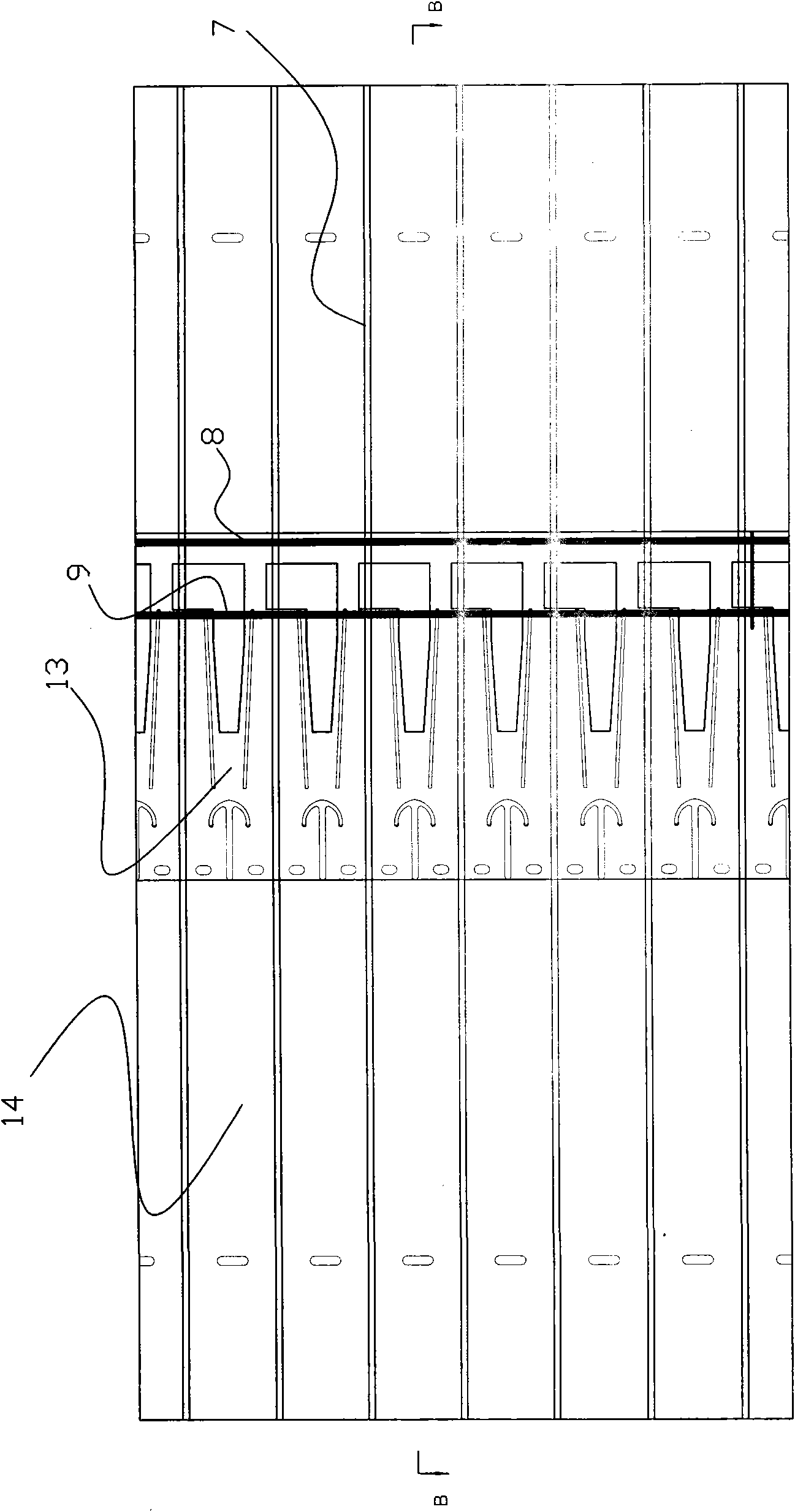

[0028] An improved air-packing device of the present invention will be further described below in conjunction with the drawings and specific embodiments.

[0029]One-time heat sealing refers to the process of forming a flat bag that can store air by heat-sealing two layers of thermoplastic film and a one-way valve. The process of thermoforming again to form a three-dimensional bag that can hold objects.

[0030] image 3 It is a preferred embodiment of the air-packing device with improved air valve of the present invention, Figure 4 is along image 3 A longitudinal sectional view of the B-B line, Figure 5 yes Figure 4 The partially enlarged schematic diagram of the A area in the figure; as can be seen from the figure, the one-way valve 13 is installed in the middle part of the sealed air chamber 14, Figure 4 with 5 It shows that the one-way valve 13 is fixed on the thermoplastic film B1 of the upper layer of the belt body, and has no adhesion with the thermoplastic f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com