Control method for conveniently adjusting stem-removing quantity of cigarette making machine

A control method and technology of cigarette making machines, applied in the fields of tobacco, cigarette manufacturing, application, etc., can solve problems such as not being able to meet the needs of shredded tobacco destemming, affecting the quality of cigarettes, and failing to meet process requirements, etc., achieving good industrial application value and promotion and application prospects , obvious effect of consumption reduction and considerable economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

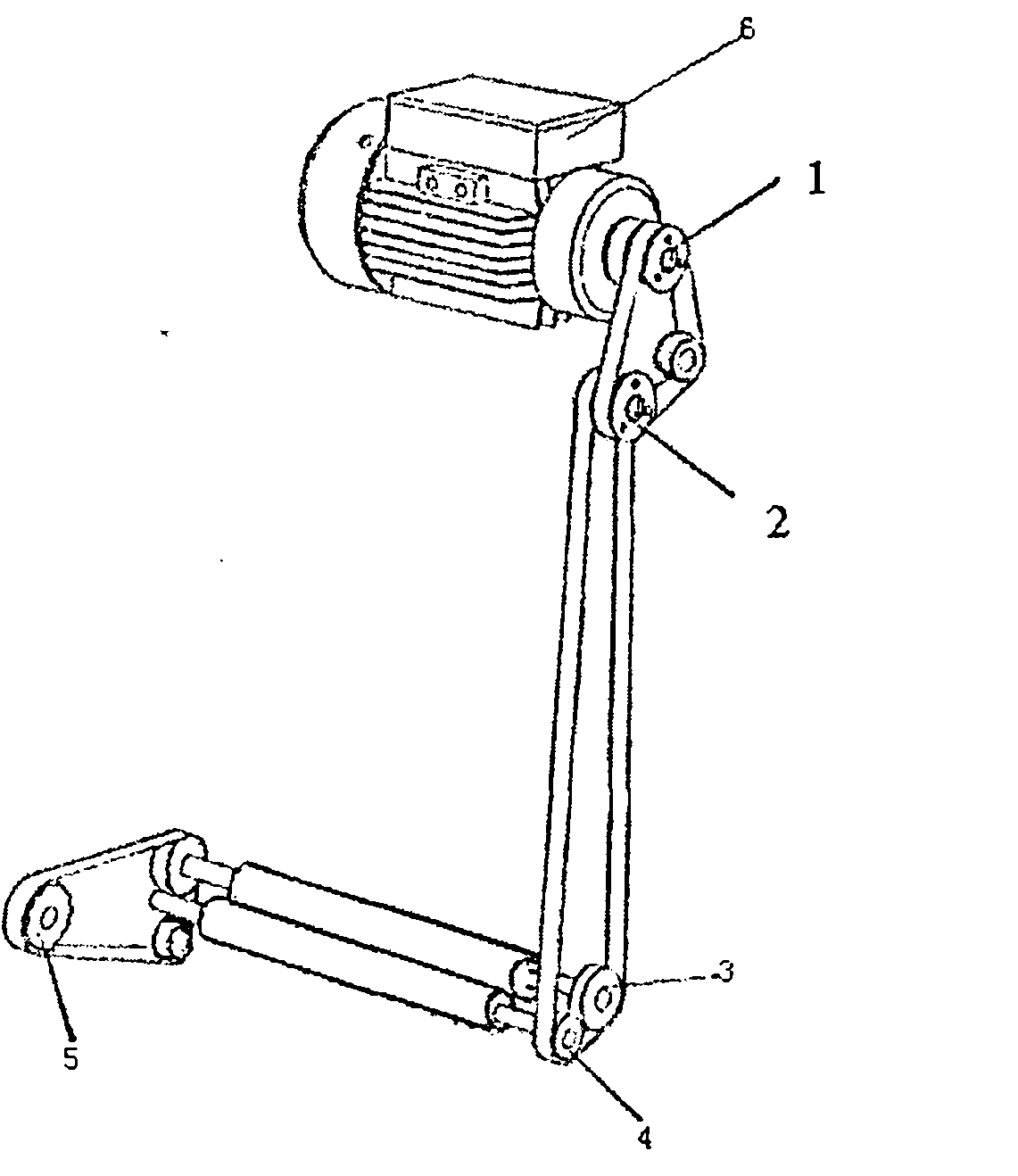

[0016] For the present invention is better described, in conjunction with accompanying drawing, give examples as follows:

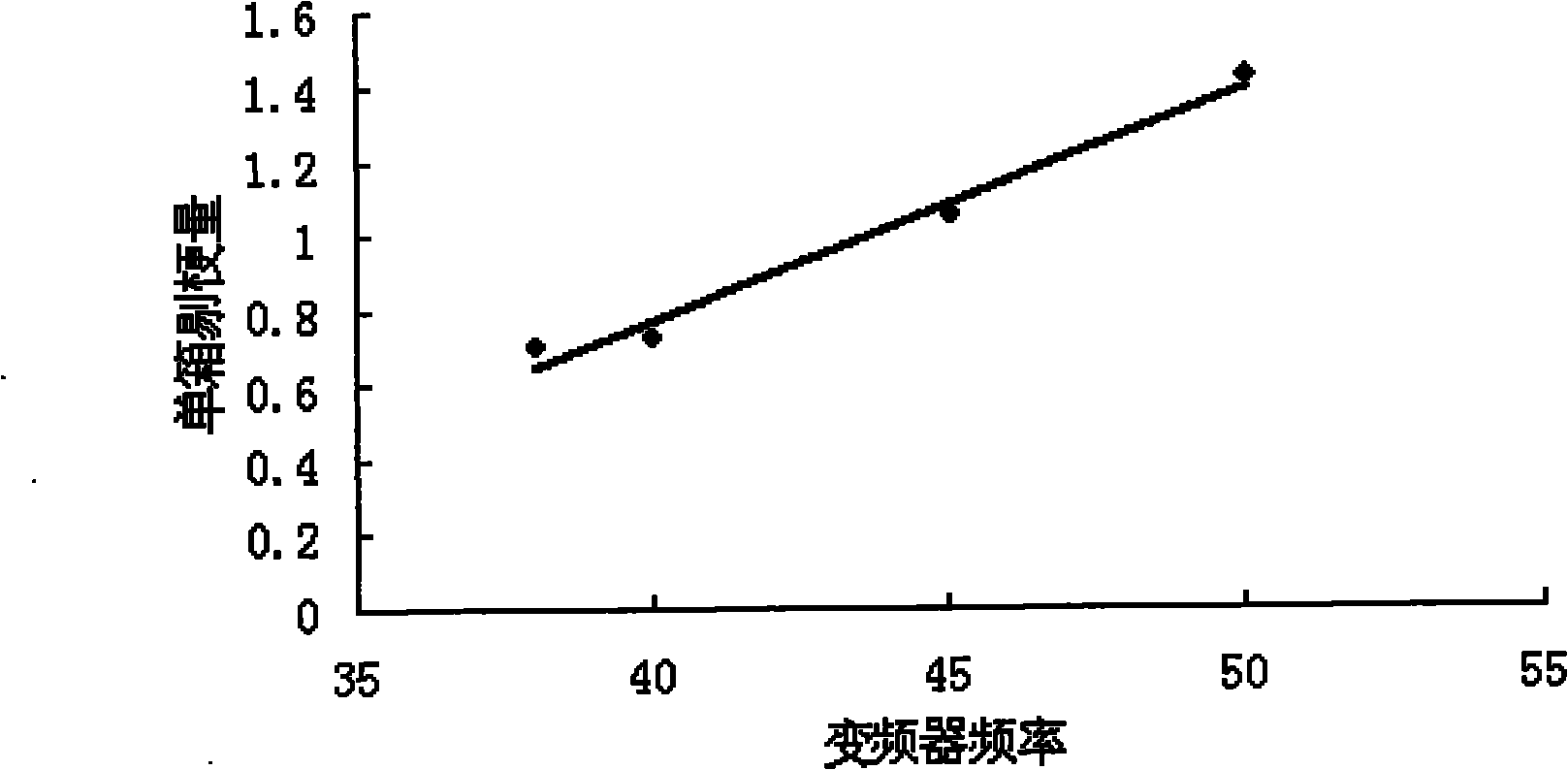

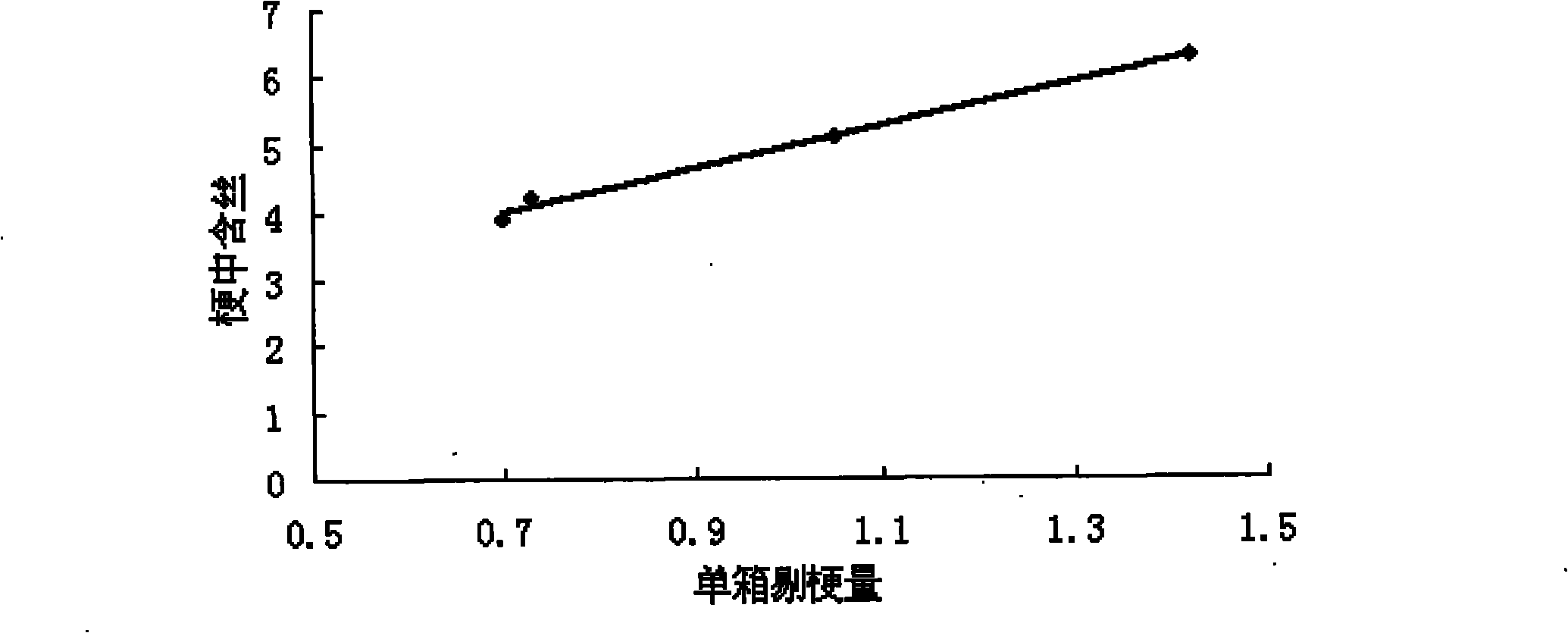

[0017] First, install a frequency converter at the control motor of the fan reel, and adjust the speed of the fan reel through the frequency converter to conduct a test. The specific test plan and results are as follows:

[0018] 1 Materials and methods

[0019] 1.1 Materials and equipment

[0020] The main production brand cigarette A (Class II) shredded tobacco is used as the test object; ZJ19B cigarette making machine; DT comprehensive test bench; rotating cage end-filtering instrument;

[0021] 1.2 Method

[0022] 1.2.1 Take 500kg of shredded tobacco of grade A, and divide it into 5 parts on average, each 100kg, 4 parts are used for testing, and 1 part is reserved.

[0023] 1.2.2 Install a frequency converter at the fan reel control motor, and use the frequency converter to adjust the speed of the spinning reel and fan reel. Choose the same ZJ19B ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com