Processed cheese and preparation method thereof

A technology of processed cheese and cheese, which is applied in the field of processed cheese and its preparation, can solve the problems of becoming fluid and unable to maintain the external shape, etc., and achieve the effect of broad market prospects and rich varieties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

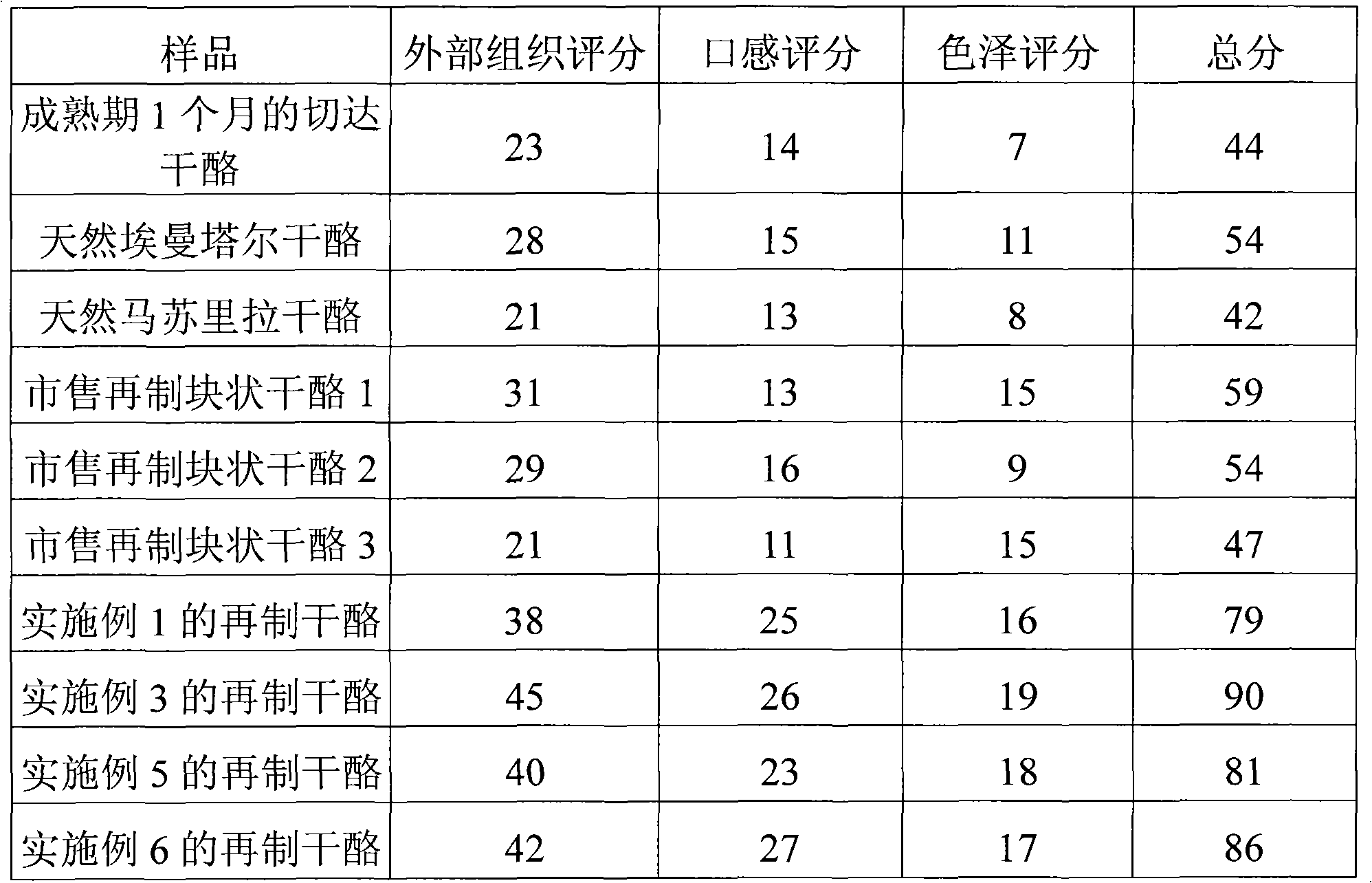

Embodiment 1

[0041] Raw materials: 50% of fresh curd; 22% of Gouda cheese with a maturation period of 4 to 6 months; 25% of water; 1% of carrageenan; 2% of emulsifying salt (sodium pyrophosphate).

[0042] Manufacturing method:

[0043] ① Cut the natural cheese into pieces (3cm×3cm), add the rest of the raw materials according to the above ratio, and shear and mix; the shear speed is 1500rpm, and the mixture is mixed at 45°C for 3min.

[0044] ②Heat the raw material to 90°C, then change the rotation speed to 300rpm, and the emulsification time to 8min;

[0045] ③ After filling, cool to 6°C at a cooling rate of 1°C / min.

[0046] According to the national standard, the nutritional components of the processed cheese products are tested as follows: protein 16.63%, of which the complete casein content accounts for 78% of the total protein content; fat 26.50%; moisture 50.05%; pH 5.7.

Embodiment 2

[0048] Raw material: Emmental cheese 40%; Edam cheese 15%; rennet casein 8%; water 25%; emulsifying salt (sodium citrate) 1%; hydrogenated soybean oil (melting point 47°C) 11%.

[0049] ① Cut the natural cheese and hydrogenated vegetable oil into pieces (3cm×3cm), add the rest of the raw materials according to the above ratio, and shear and mix; the shear speed is 1200rpm, and the mixture is mixed at 40°C for 5min.

[0050] ②Heat the raw material to 92°C, then change the rotation speed to 500rpm, and the emulsification time to 6min;

[0051] ③ After filling, cool to 8°C at a cooling rate of 0.5°C / min.

[0052] The nutritional components of processed cheese products were detected as follows: protein 19.58%, of which complete casein content accounted for 75% of the total protein content; fat 30.24%; moisture 44.14%; pH 5.9.

Embodiment 3

[0054] Ingredients: Cheddar cheese aged 3 months 40%; Emmental cheese 20%; rennet casein 12%; water 18%; emulsifying salt 2% (sodium citrate 0.5%; sodium pyrophosphate 1% 0.5% sodium hexametaphosphate); 1% carrageenan; 7% hydrogenated soybean oil with a melting point of 41°C.

[0055] ① Cut natural cheese and hydrogenated soybean oil into pieces, add the rest of the raw materials according to the above ratio, and shear and mix; the shear temperature is 50°C, the mixing time is 3 minutes, and the shear speed is 1500 rpm;

[0056] ②Heat the raw material to 92°C, then change the rotation speed to 600rpm, and the emulsification time to 7min;

[0057] ③ After filling, cool to 8°C at a cooling rate of 0.8°C / min.

[0058] Processed cheese: protein 23.67%, of which complete casein accounts for 80% of the total protein content; fat 22.78%; moisture 38.88%; pH 5.7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com