Method for evaluating adhesion performance of coating of cold rolled automobile sheet

An adhesion, automotive board technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problems of difficulty in testing the "P ratio" value of phosphating films, errors in test results, and high requirements for operators to avoid problems. Loss, strong anti-interference ability, accurate test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific embodiment of the present invention is described further below:

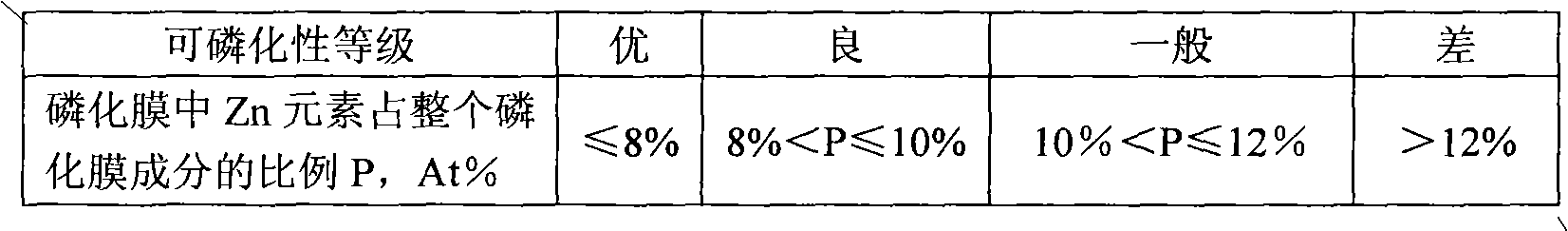

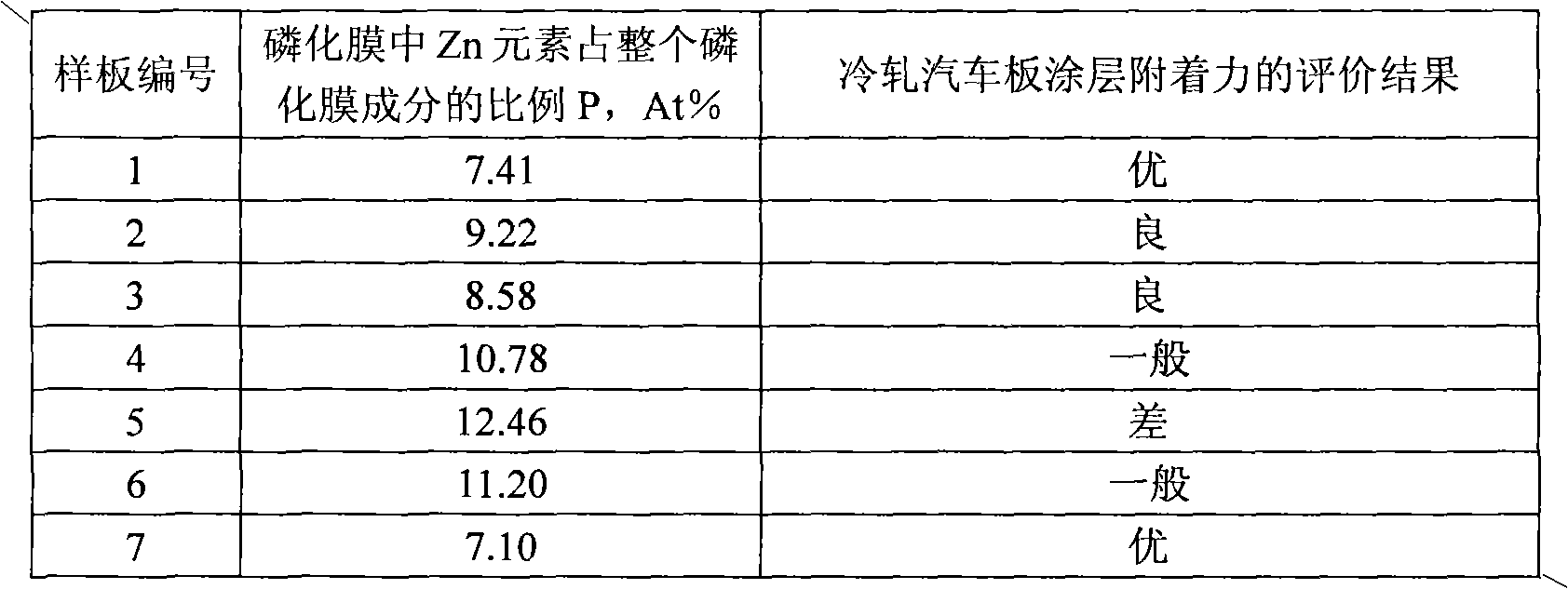

[0014] The adhesion performance of the coating was predicted by measuring the ratio of Zn element in the phosphating film on the surface of 7 kinds of cold-rolled automobile sheets to the composition of the entire phosphating film, as follows:

[0015] Step 1: Take 7 kinds of cold-rolled automobile sheets that have undergone zinc-based phosphating treatment but have not been painted, and cut them into templates with a side length (or diameter) of 10-50 mm, numbered 1-7 respectively.

[0016] Step 2: After the sample is cleaned and dried, put it into an energy dispersive spectrometer (EDS) for surface scanning, collect and test the characteristic energy of X-ray photons of various elements in the phosphating film on the surface of the sample, and calculate according to the collected test results The ratio of Zn element in the phosphating film on the surface of cold-rolled automobile sheet to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com