Method for measuring flow of conductive fluid in non-full pipe by using electromagnetic flow meter

A technology of electromagnetic flowmeter and conductive fluid, which is applied in the application of electromagnetic flowmeter to detect fluid flow, volume/mass flow generated by electromagnetic effects, etc., which can solve the problems of measurement accuracy and achieve the effect of ensuring accuracy and overcoming measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

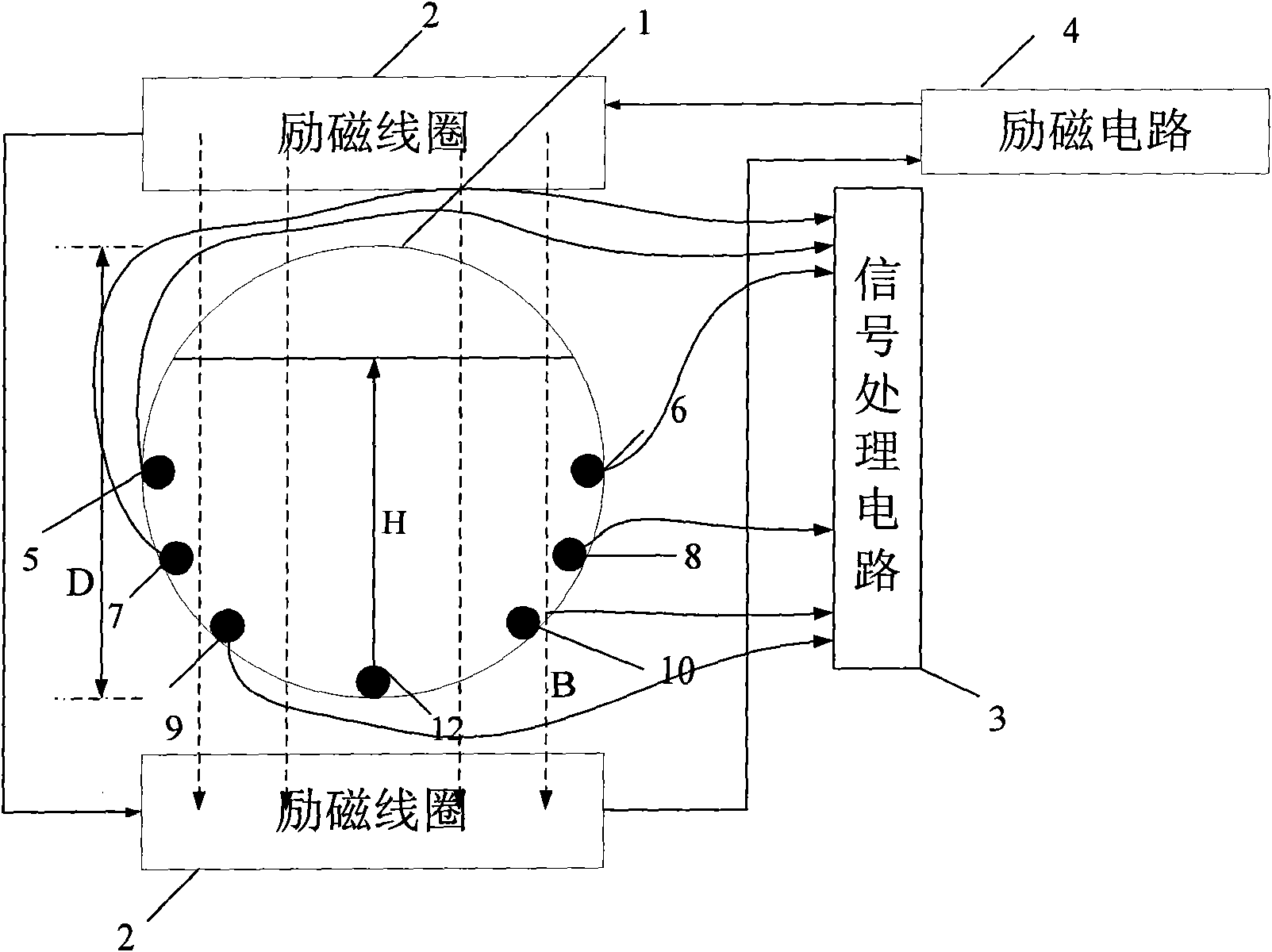

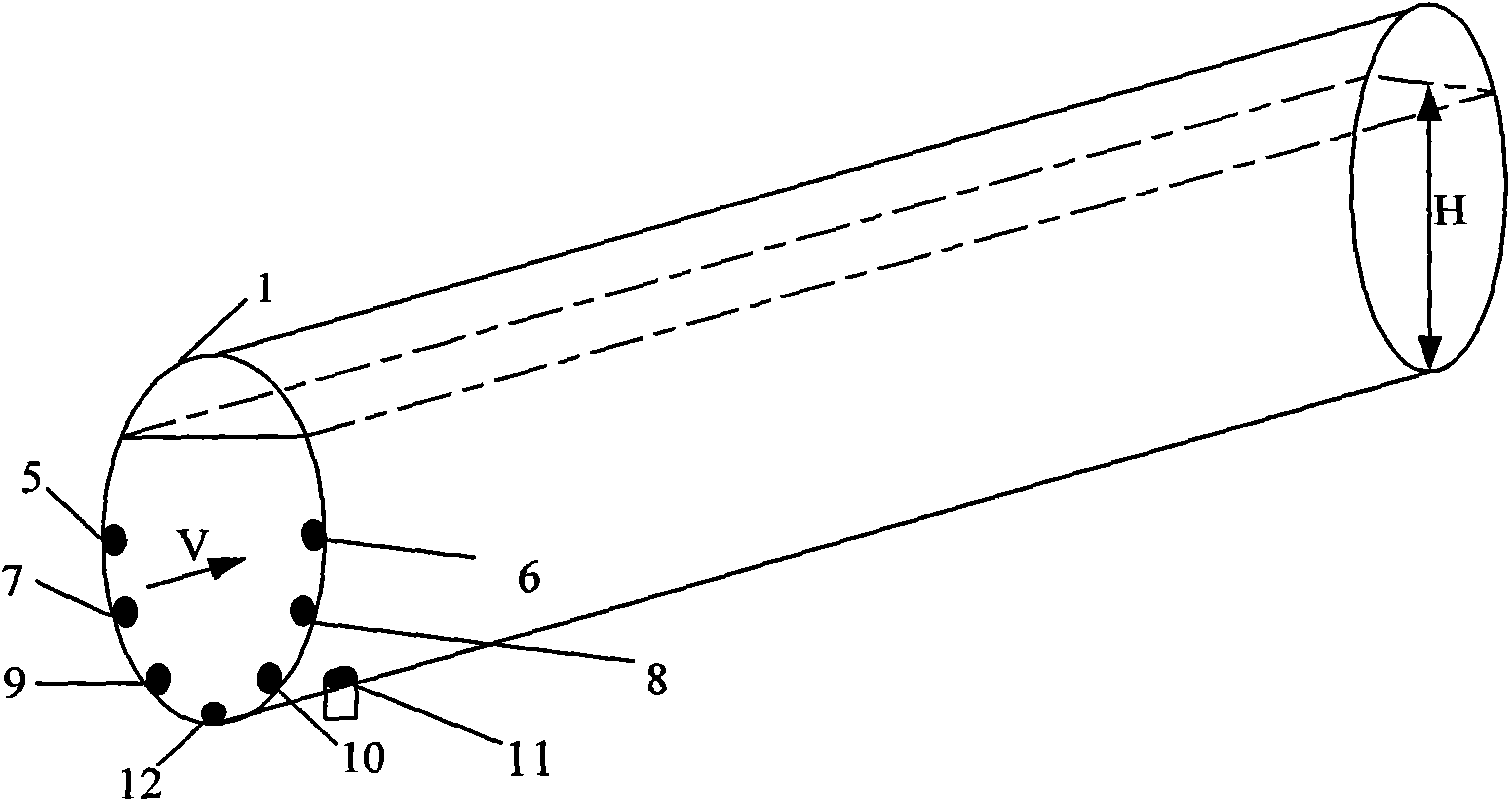

[0014] A preferred embodiment of the present invention is as follows: see figure 1 and figure 2 .

[0015] The method for measuring the flow of a conductive fluid in a partially filled pipe with an electromagnetic flowmeter includes the following steps:

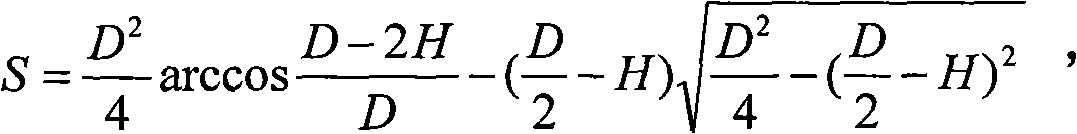

[0016] 1) Connect the partially filled electromagnetic flowmeter to the fluid pipeline to be measured. The measuring tube 1 of the partially filled electromagnetic flowmeter is provided with an excitation coil 2 up and down. The excitation coil 2 is connected to the excitation circuit 4, and the inner wall of the pipeline is distributed There are three pairs of measuring electrodes, each pair of measuring electrodes is input into the signal processing circuit 3 in the form of a differential signal, and the three pairs of measuring electrodes are respectively connected to the signal processing circuit, and the ground electrode 12 at the bottom of the measuring tube 1 communicates with the excitation circuit 4 and the signal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com