Multilayer gas distribution full circulation carbonization furnace

A full cycle, dry distillation furnace technology, applied in the field of coal chemical industry, can solve the problems of reducing thermal efficiency and oil recovery rate, affecting the effect of dry distillation, and difficulty in uniform heating, etc., and achieve the effect of remarkable dry distillation effect, improved thermal efficiency, and complete dry distillation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

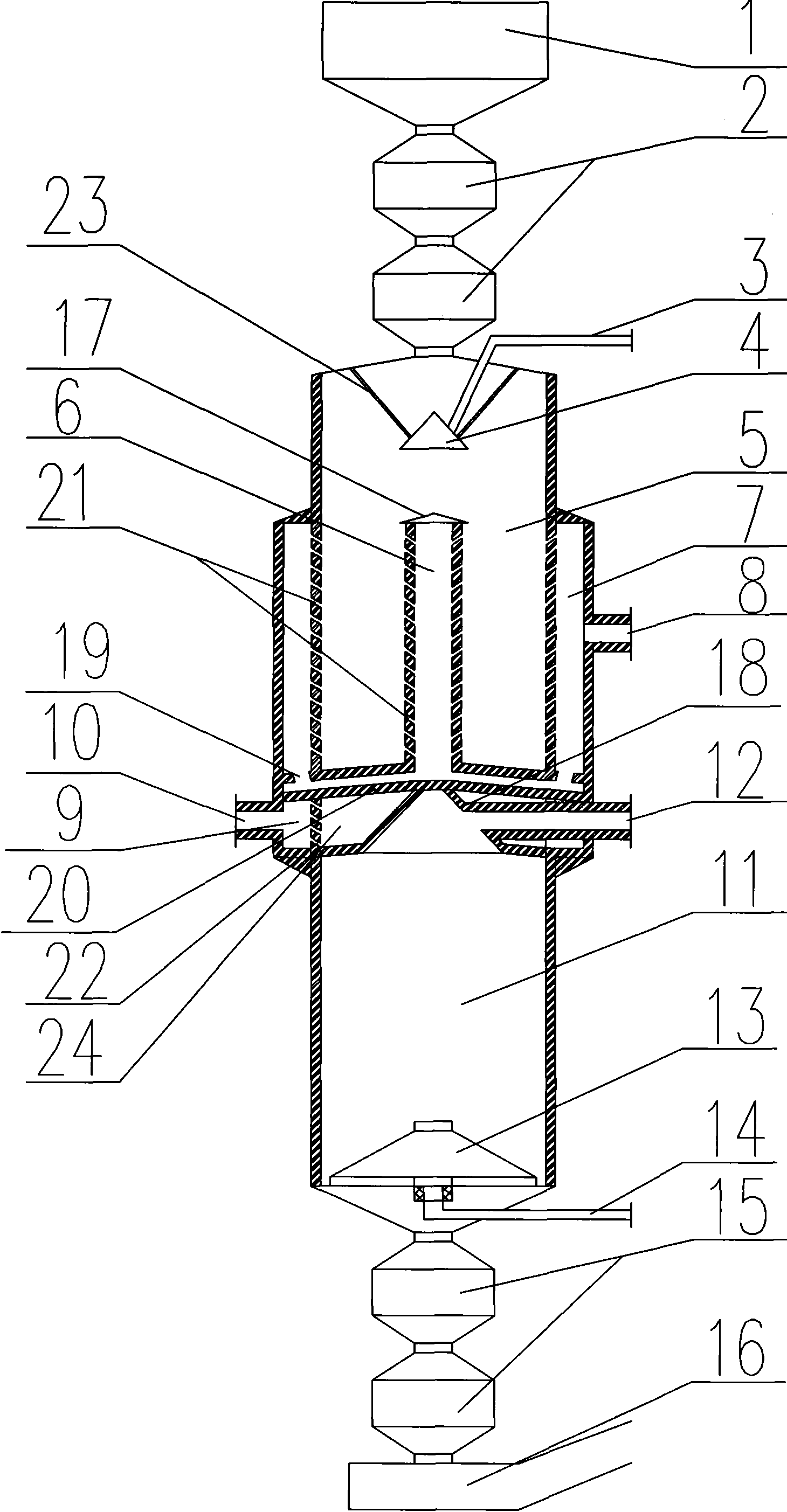

[0009] As shown in the figure, the present invention is composed of a furnace body and a discharge system and a slagging system at the top and bottom of the furnace body; the discharge system at the top of the furnace body includes a storage bin 1 and a lower hopper 2, and the lower hopper 2 is composed of The upper and lower valves are separated. The slagging system at the bottom of the furnace body includes an ash discharge hopper 15 and ash water cooling tank 16, and the ash discharge hopper 15 is two upper and lower ones separated by a valve. The above-mentioned double lower hopper 2 is used for feeding, and the double-row ash hopper 15 is used for ash discharge, which ensures that the gas in the retort furnace does not leak when discharging or slagging, and improves the capacity of a single furnace; the furnace body is divided into each other by the arch legs 20 in the middle. Connected dry distillation section 5 and generation section 11. The arched leg 20 is a hollow c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com