Wafer grinding method

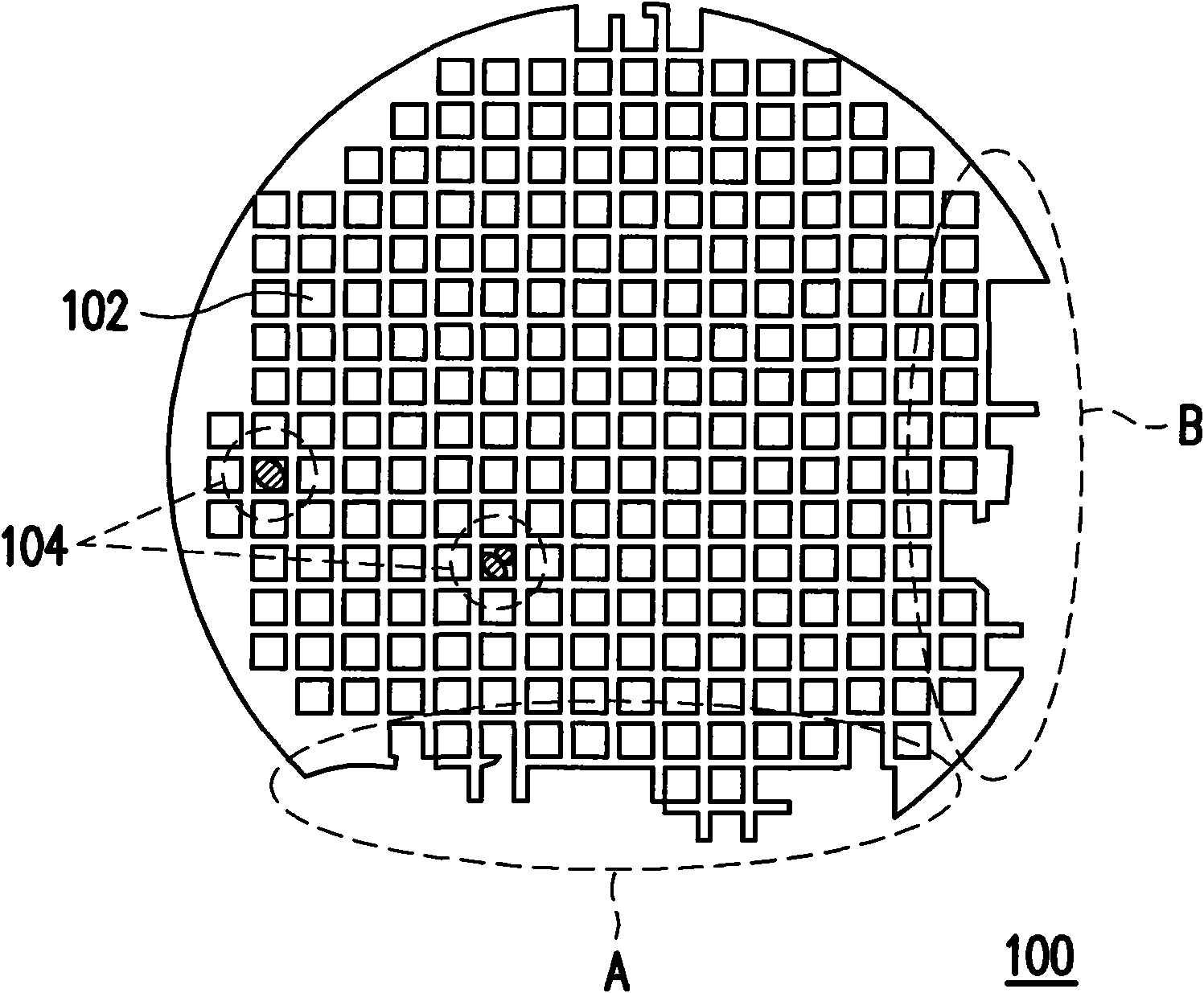

A grinding method and wafer technology, applied in the direction of grinding devices, grinding machine tools, precision positioning equipment, etc., can solve the problems of weak strength, cracking, silicon slag easily stuck in the opening 102, etc., and achieve the effect of improving the yield rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to make the above-mentioned objects, features and advantages of the present invention more obvious and easy to understand, the preferred embodiments of the present invention are exemplified below, and are described in detail as follows in conjunction with the accompanying drawings:

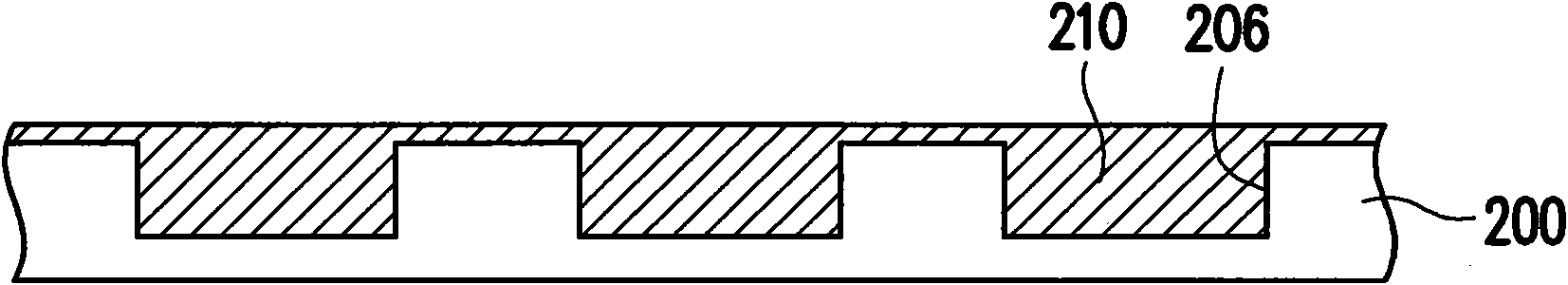

[0024] Please refer to Figures 2A to 2F It is a schematic diagram of a wafer grinding method according to an embodiment of the present invention. Please refer to the following steps:

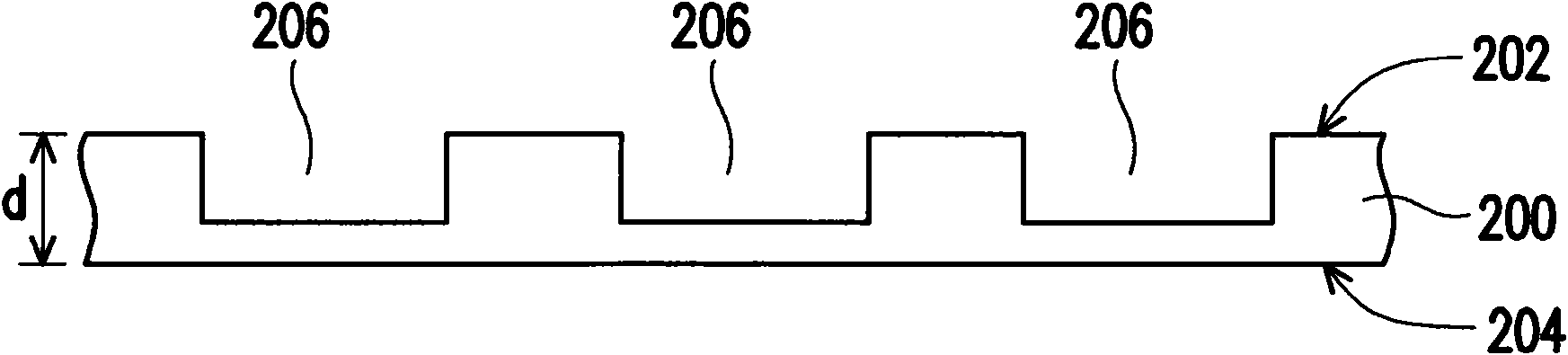

[0025] First, the first step is to provide a wafer 200, the wafer has a first surface 202, a second surface 204 and a plurality of openings 206 recessed in the first surface 202, and the wafer 200 has a thickness d.

[0026] Please refer to Figure 2A , in the first step of this embodiment, dry etching or wet etching is performed on the first surface 202 of the wafer 200, so that a plurality of openings 206 (or cavities) are formed on the first surface 202 of the wafer 200, The depths of these op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com