Multi-head high-speed grinder

A high-speed grinding, multi-head technology, applied in the field of grinding, can solve the problems of poor grinding smoothness, reduce grinding accuracy, restrict the scope of use, etc., and achieve the effects of large grinding volume, improved grinding accuracy, and reasonable design structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

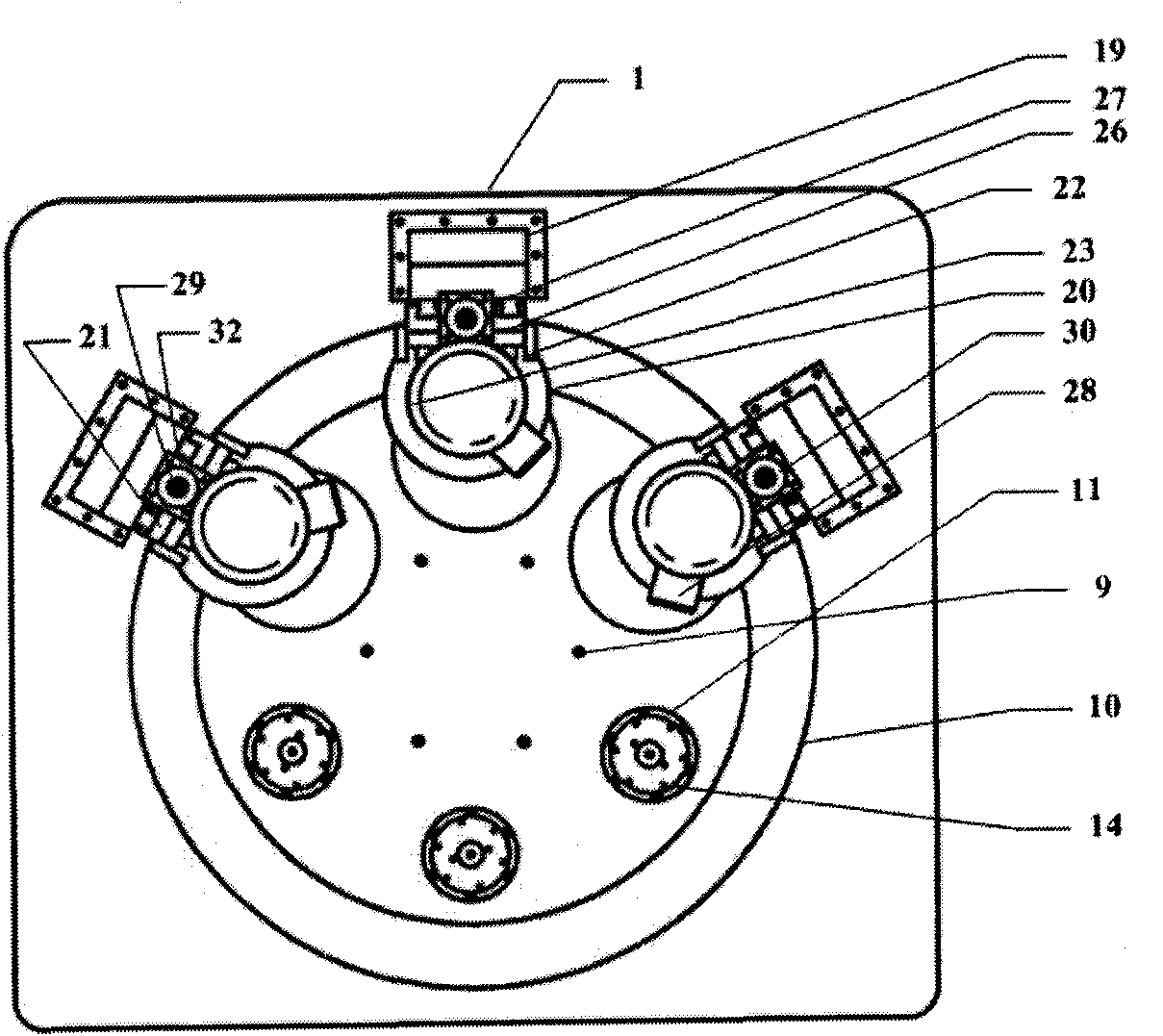

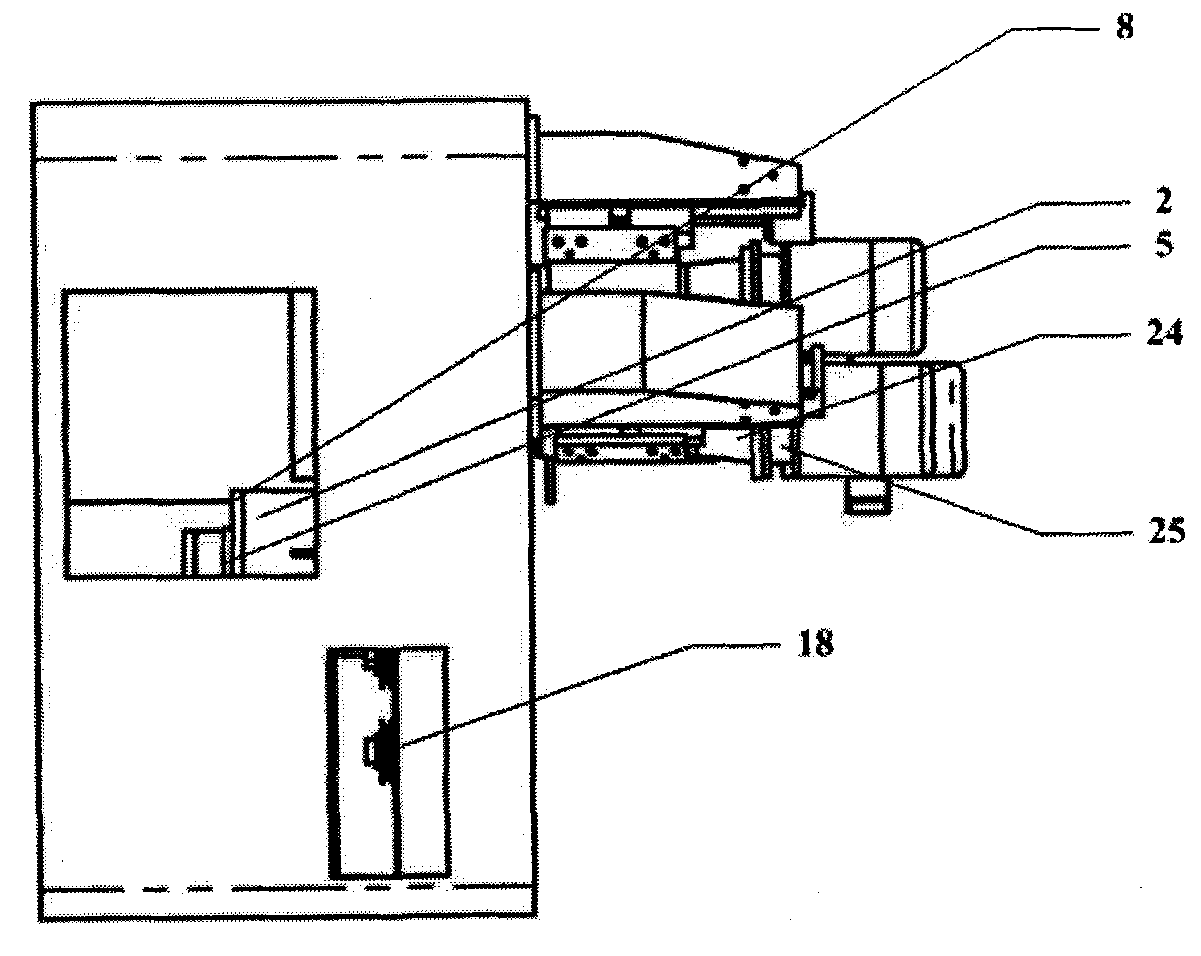

[0026] In order to describe the present invention more clearly, the present invention will be further described below in conjunction with the accompanying drawings.

[0027] Such as figure 1 and figure 2 As shown, the present invention provides a multi-head high-speed grinding machine, which is composed of a transmission part installed in the frame 1, an upper grinding disc part and a lower grinding disc part, and the transmission part consists of an upper grinding head main motor 23, a lower disc motor 5 and an upper grinding disc The head servo motor 26 constitutes. Wherein, the upper grinding head 32 in the upper grinding disc part is connected with the upper grinding head main motor 25, and the grinding head shaft grinding wheel 28 is also installed on the upper grinding head 32. The upper grinding head is directly connected with the high-speed motor, so that the speed of the upper grinding head can reach 2900 rpm, and the grinding capacity is larger. The feed rate of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com