Silvered aluminum powder as well as preparation method and application thereof

A technology of silver-plated aluminum and aluminum powder, which is applied in the treatment of dyed low-molecular organic compounds, fibrous fillers, etc., can solve the problems of high surface activity of aluminum powder, unstable plating solution, and difficult plating, and achieve good anti-electromagnetic Effects of interference, low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

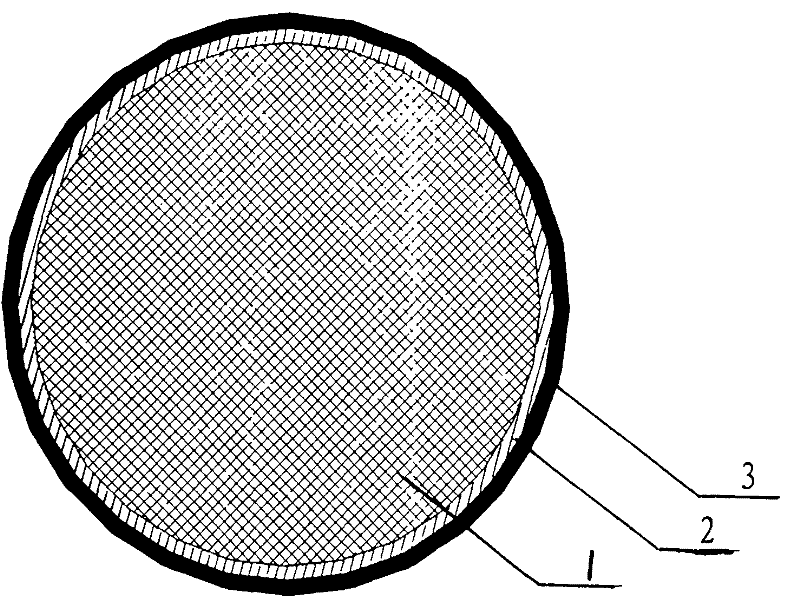

Image

Examples

Embodiment 1

[0035] a. first according to the copper sulfate solution whose concentration is 5g / L: the monosodium ethylenediaminetetraacetic acid solution=5:30 parts by weight of 80g / L is mixed with the concentration, stirred for 20 minutes to make it fully complexed, and then Use ammonia water to adjust the pH to 10, then put aluminum powder of 200 mesh spherical aluminum particles into it, continue to stir, wait until the plating solution is clarified, wash it with water until neutral, and obtain copper-plated aluminum powder;

[0036] b. According to the proportioning of aluminum powder: silver nitrate=100:45 parts by weight, get silver nitrate and add 10 times of water to get silver nitrate aqueous solution;

[0037] c. Put the copper-coated aluminum powder in step a in the 0.005g / L ethylenediaminetetraacetic acid monosodium salt solution, stir for 5 minutes at 80°C, and then control it within 60 minutes under stirring Slowly add the silver nitrate aqueous solution of step b, and then ...

Embodiment 2

[0040] a. first according to concentration is the copper sulfate solution of 50g / L:concentration is the ethylenediaminetetraacetic acid monosodium salt solution=20:10 weight ratio of 10g / L mixes, stirs 40 minutes, makes it fully complexed, then Use ammonia water to adjust the pH to 7.5, then put the aluminum powder of 1500 mesh spherical aluminum particles into it, continue to stir, wait until the plating solution is clarified, wash it with water until it is neutral, and obtain copper-plated aluminum powder;

[0041] b. according to the proportioning of aluminum powder: silver nitrate=100:5 parts by weight, get silver nitrate and add 25 times the amount of water to get silver nitrate aqueous solution;

[0042]c. Put the copper-coated aluminum powder in step a in 0.1g / L ethylenediaminetetraacetic acid monosodium salt aqueous solution, stir at 20°C for 20 minutes, and then control it within 20 minutes under stirring Slowly add the silver nitrate aqueous solution of step b, and t...

Embodiment 3

[0045] a. first according to the copper sulfate solution whose concentration is 25g / L: concentration is 50g / L the monosodium ethylenediamine tetraacetic acid salt solution=12: 20 parts by weight proportioning mixes, stirs 30 minutes, makes it fully complexed, then Use ammonia water to adjust the pH to 9.0, then put the aluminum powder of 800 mesh spherical aluminum particles into it, continue to stir, wait until the plating solution is clarified, wash it with water until it is neutral, and obtain copper-plated aluminum powder;

[0046] b. According to the proportioning of aluminum powder: silver nitrate=100:25 parts by weight, get silver nitrate and add 20 times of water to get silver nitrate aqueous solution;

[0047] c. Put the copper-coated aluminum powder in step a in an aqueous solution of 0.05 g / L ethylenediaminetetraacetic acid monosodium salt, stir at 50°C for 12 minutes, and then control it within 40 minutes under stirring Slowly add the silver nitrate aqueous solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com