Preparation method of processed cheese and processed cheese prepared thereby

A technology for processing cheese and natural cheese, applied in cheese substitutes, dairy products, applications, etc., can solve problems such as melting, softening, and inability to cook, and achieve easy operation, good chewiness, texture and taste. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

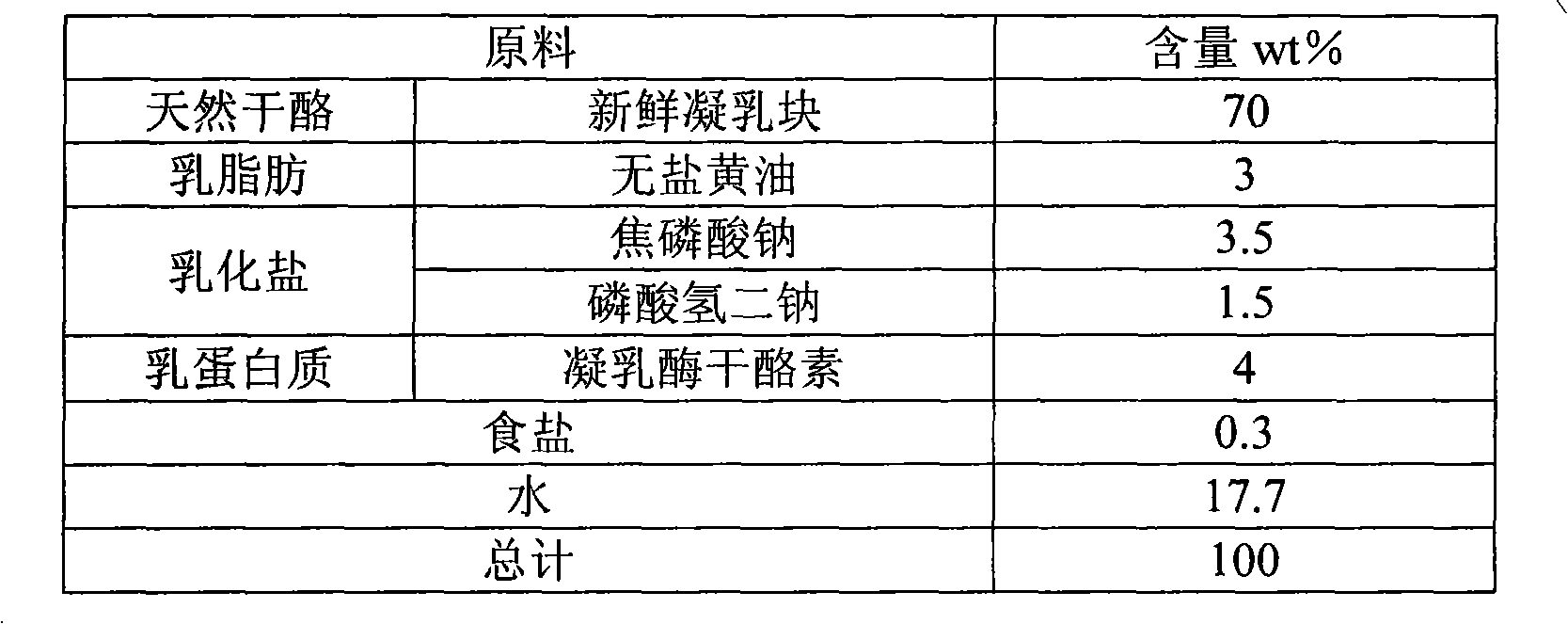

[0034] formula:

[0035]

[0036] Manufacturing method:

[0037] ① Cut the natural cheese and milk fat into pieces according to the proportion, then add the rest of the ingredients, shear and mix, heat up to 70°C to melt initially, and stir for 5 minutes to obtain the mixture;

[0038] ②Sterilization: adopt pasteurization treatment, heat up to 95°C and keep for 5s;

[0039]③ Stirring and emulsification: Stir for 5 minutes at a temperature of 85°C and a rotation speed of 1200rpm;

[0040] ④Slow cooling: cooling in an interlayer water bath for 40 minutes to make the material center temperature reach 30°C;

[0041] ⑤ Refrigerated storage: refrigerated at 5°C for 6 hours;

[0042] ⑥Re-melting: cut the pre-obtained processed cheese into pieces, heat up to 85°C for initial melting, and stir for 10 minutes;

[0043] ⑦ Ultra-high temperature instantaneous sterilization: keep the temperature at 137°C and sterilize for 4s;

[0044] ⑧Stir and emulsify again: Stir for 5 minutes at...

Embodiment 2

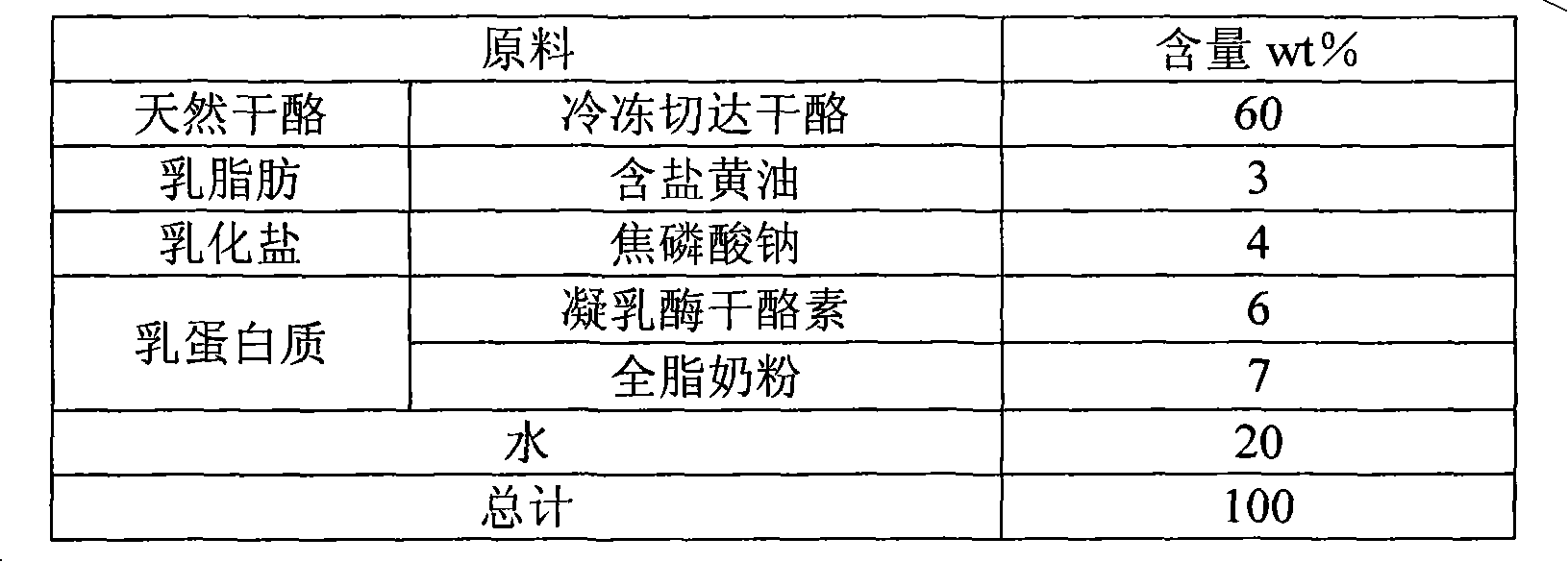

[0048] formula:

[0049]

[0050] Manufacturing method:

[0051] ① Cut the natural cheese and milk fat into pieces according to the proportion, then add the rest of the raw materials, shear and mix, heat up to 80°C and initially melt, stir for 5 minutes to obtain the mixture;

[0052] ②Sterilization: adopt pasteurization treatment, heat up to 85°C and keep for 5min;

[0053] ③ Stirring and emulsification: Stir for 5 minutes at a temperature of 80°C and a rotation speed of 1200rpm;

[0054] ④ Slow cooling: cooling in interlayer water bath for 30 minutes to make the material center temperature below 30°C;

[0055] ⑤ Refrigerated storage: refrigerated at 4°C for 2 hours;

[0056] ⑥Re-melting: cut the pre-obtained processed cheese into pieces, heat up to 85°C for initial melting, and stir for 5 minutes;

[0057] ⑦ Ultra-high temperature instantaneous sterilization: keep the temperature at 140°C and sterilize for 2s;

[0058] ⑧Stir and emulsify again: Stir for 5 minutes at ...

Embodiment 3

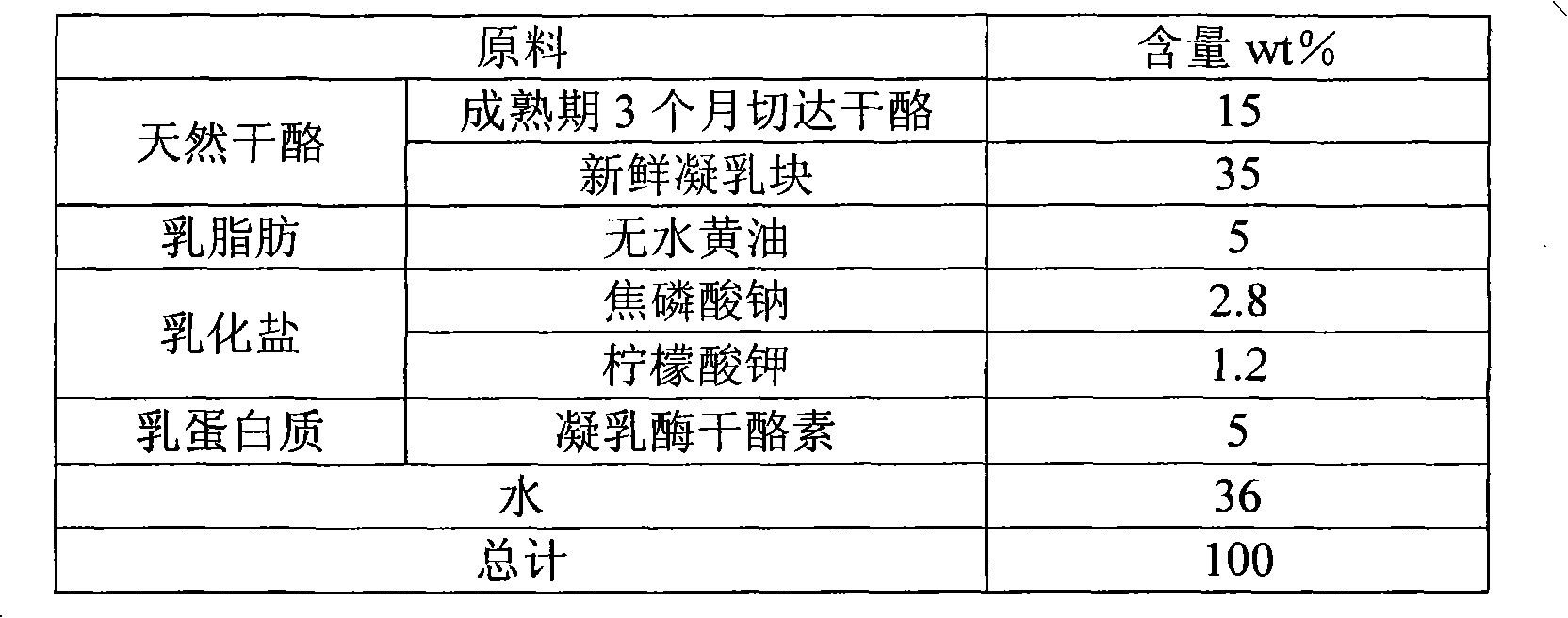

[0062] formula:

[0063]

[0064] Manufacturing method:

[0065] ① Cut the natural cheese and milk fat into pieces according to the proportion, then add the rest of the raw materials, shear and mix, heat up to 70°C to melt initially, and stir for 5 minutes to obtain the mixture;

[0066] ② Sterilization: Use ultra-high temperature instant sterilization treatment, heat up to 135°C, and keep for 9s;

[0067] ③ Stirring and emulsification: Stir for 15 minutes at a temperature of 85°C and a rotation speed of 900 rpm;

[0068] ④Slow cooling: cooling in an interlayer water bath for 40 minutes to make the material center temperature below 30°C;

[0069] ⑤ Refrigerated storage: refrigerated at 10°C for 12 hours;

[0070] ⑥Re-melting: cut the pre-obtained processed cheese into pieces, heat up to 80°C for initial melting, and stir for 10 minutes;

[0071] ⑦ Ultra-high temperature instantaneous sterilization: keep the temperature at 135°C and sterilize for 9s;

[0072] ⑧Stir and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com