Divided-flow vacuum pump unit water cooling device

A technology of water cooling device and vacuum pump, applied in the direction of variable capacity pump components, liquid variable capacity machinery, pump components, etc., can solve the problems of vacuum pump burnout, waste of water resources, shortening the service life of vacuum pump, etc., to prevent overheating and burning damage, saving water resources and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

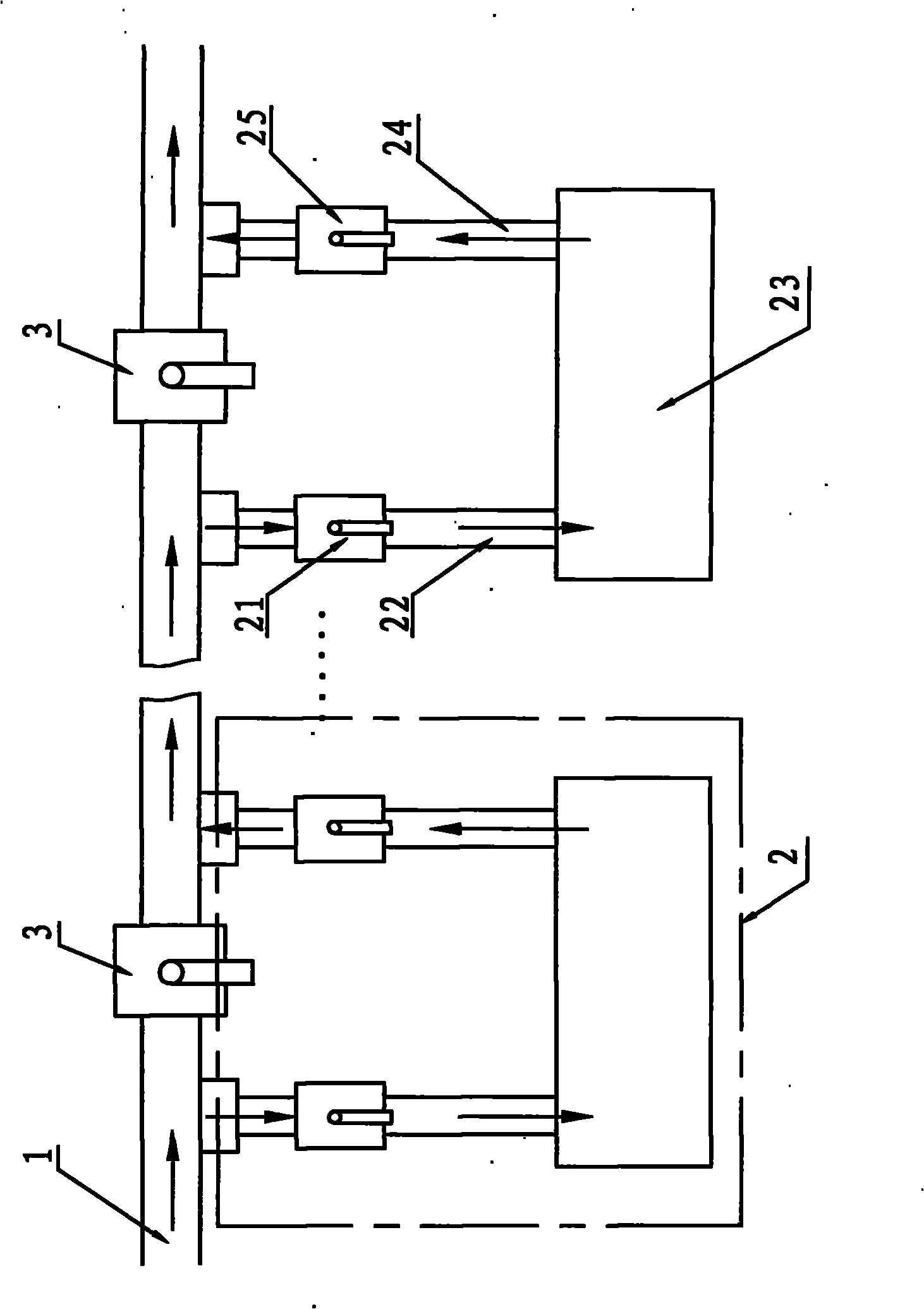

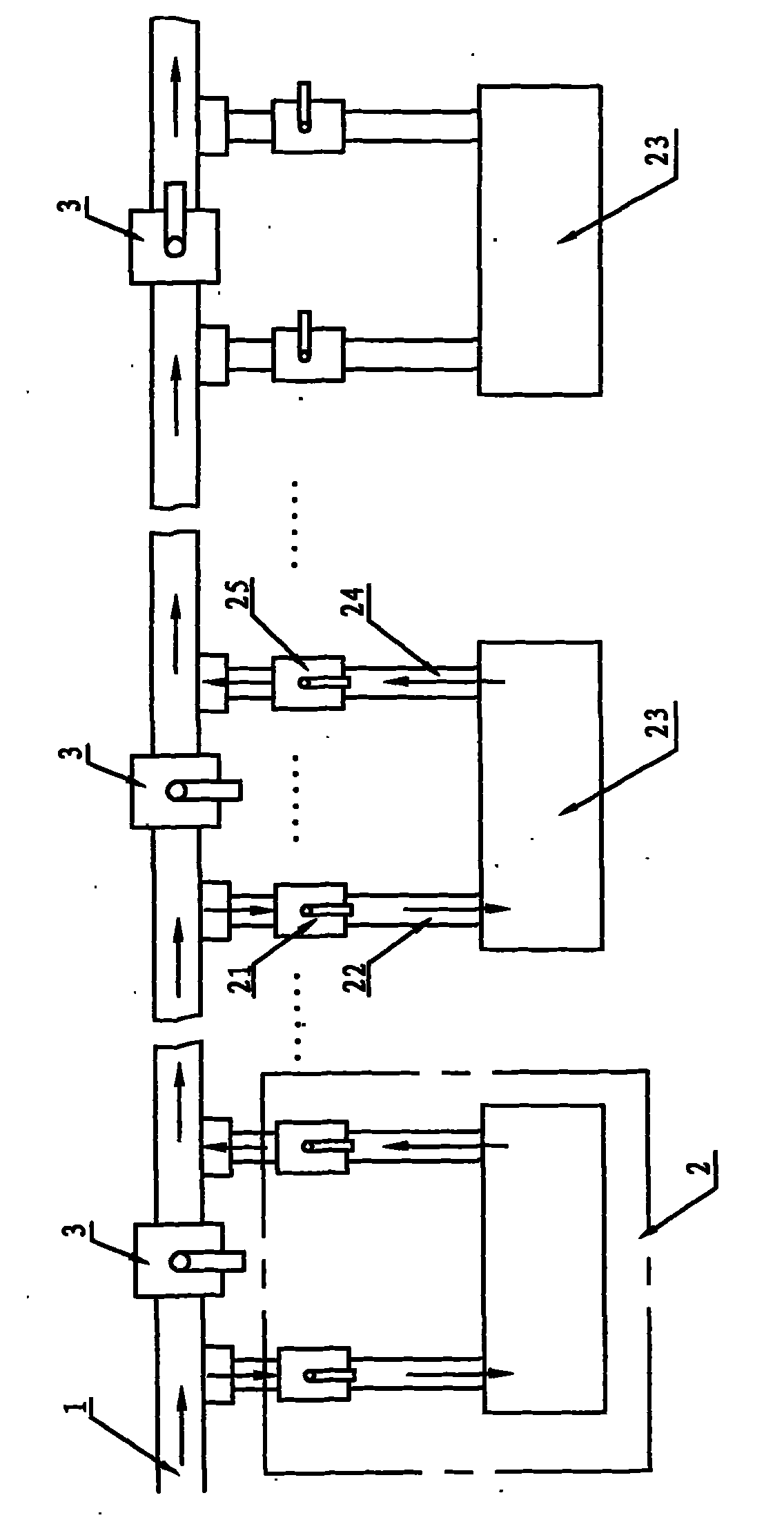

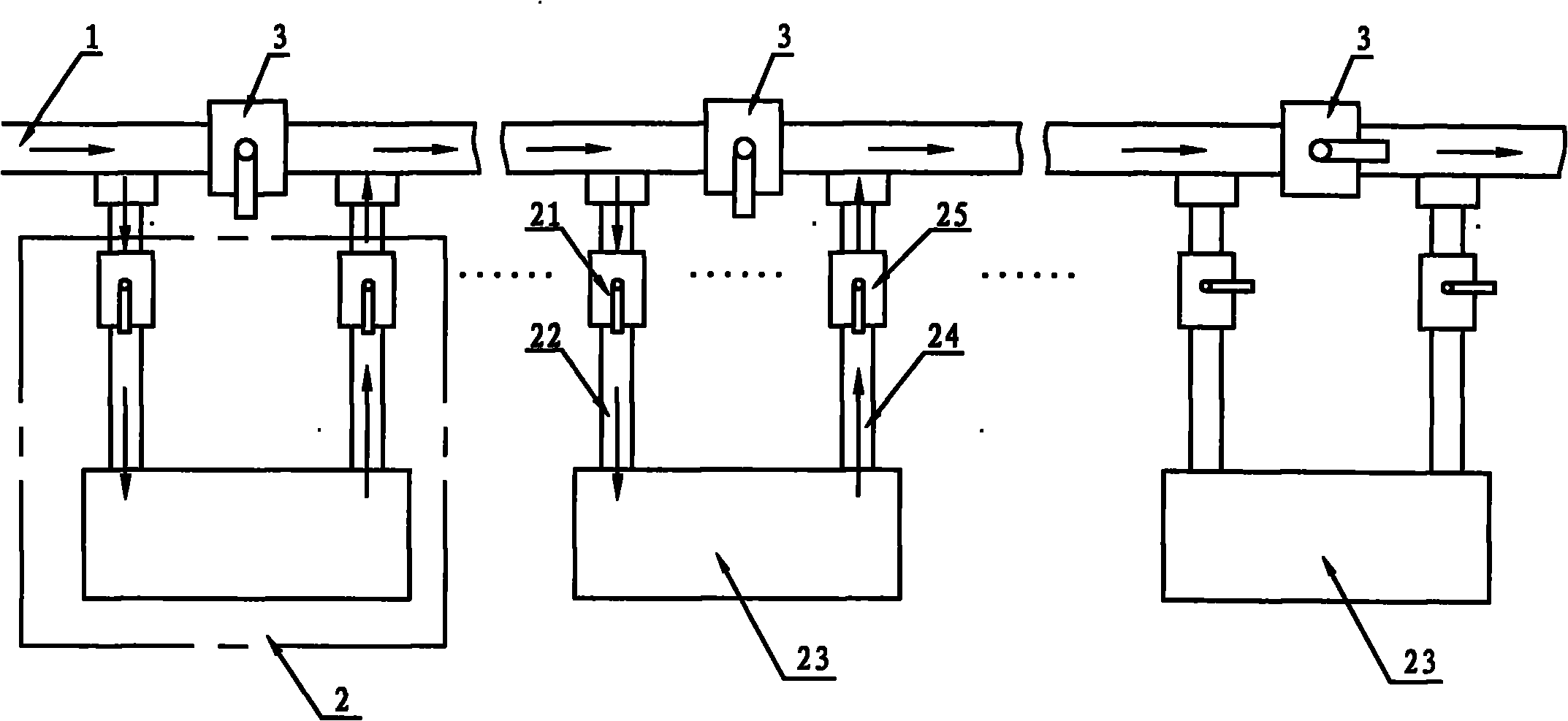

[0014] The water cooling device of the split flow vacuum pump unit, such as figure 1 As shown in ~3, it includes a main water inlet pipe 1, several vacuum pump cooling units 2 and several main control valves 3, all vacuum pump cooling units 2 are connected to the main water inlet pipe 1 in turn, and each vacuum pump cooling unit 2 All are composed of water inlet branch valve 21, water inlet branch pipe 22, vacuum pump 23, water outlet branch pipe 24 and water outlet branch valve 25, water inlet branch pipe 22 is connected to main water inlet pipe 1 through water inlet branch valve 21 , the water outlet branch pipe 24 is connected to the main water inlet pipe 1 through the water outlet branch valve 25, the water inlet branch pipe 22 and the water outlet branch pipe 24 are connected to the cooling water cavity of the vacuum pump 23, and the main control valve 3 is installed in series On the main water inlet pipe 1 , and each main control valve 3 is arranged between the connectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com