Fault processing method of high pressure water enrichment area

A treatment method and technology for faults, applied in drainage, earthwork drilling, wellbore lining, etc., can solve problems such as long construction time, hidden safety hazards in tunnel construction, water inrush, mud inrush, etc., to improve safety and reliability, shorten the The effect of grouting construction period and reducing water pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

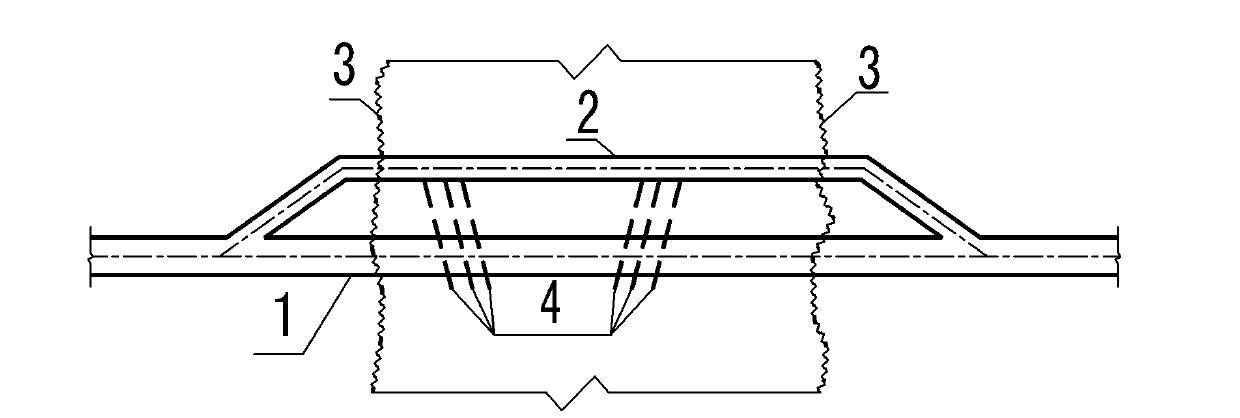

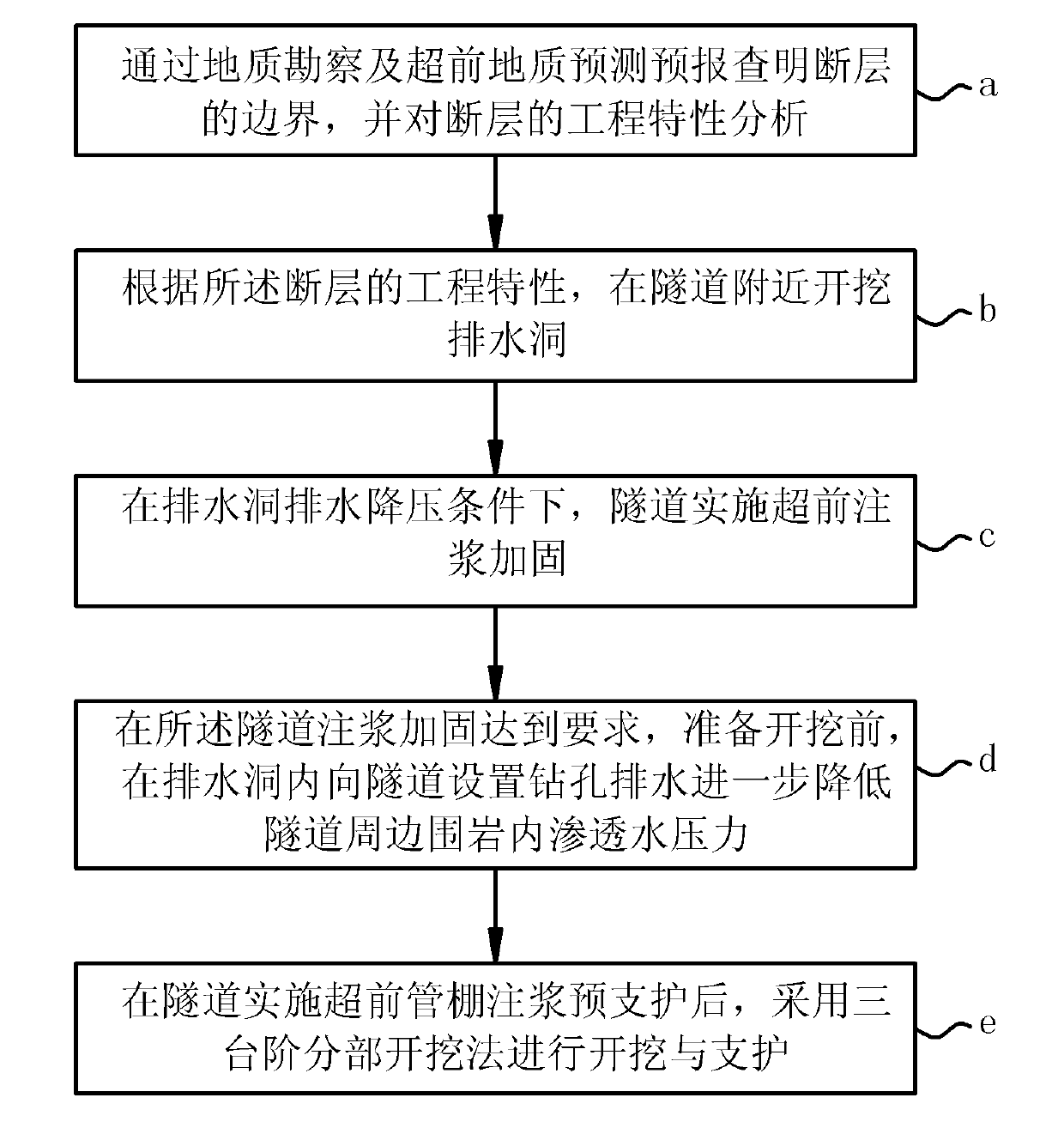

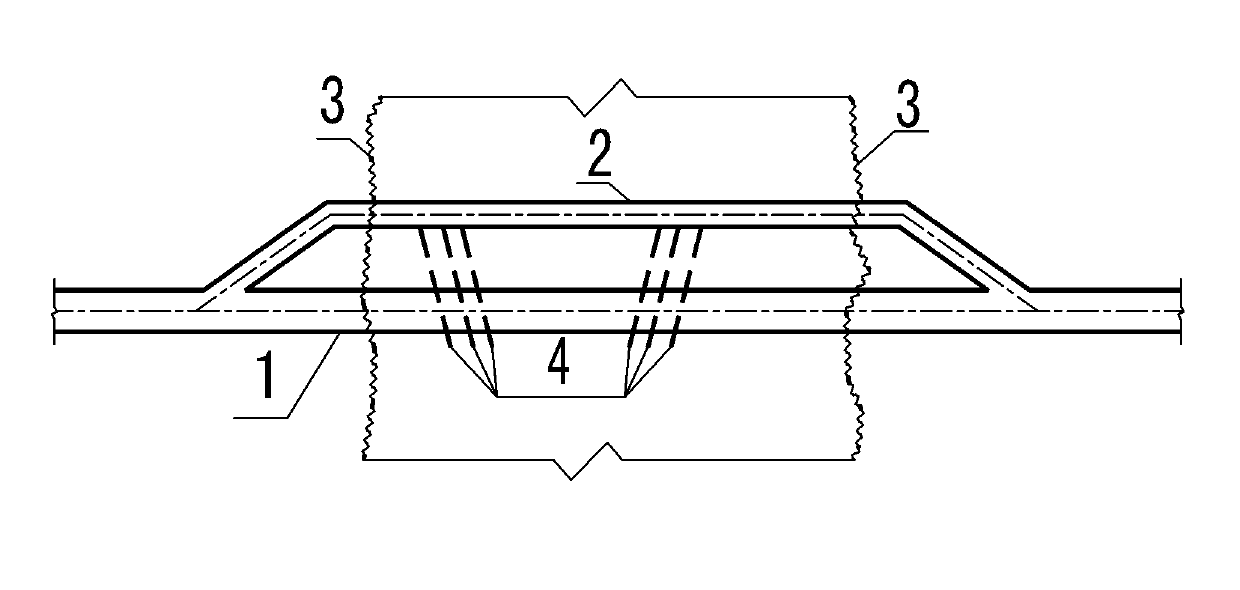

[0024] Example: as figure 1 , 2 As shown, the processing method of this embodiment includes the following steps:

[0025] Step a. Identify fault boundary 3 through geological survey and advance geological prediction and forecast, and analyze the engineering characteristics of the fault. Geophysical exploration and drilling methods are used in tunnel 1 to identify fault boundaries 3. Specifically, electrical methods, electromagnetic methods, seismic wave methods, acoustic wave methods or infrared methods can be used for advanced geological prediction and prediction; the engineering characteristics analysis of faults is mainly for geological surveys. , surface deep holes, and advanced prediction and forecast data are comprehensively analyzed, and some important characteristics that must be possessed by fault treatment are obtained, such as the direction of water inflow of the fault, the boundary mileage of the fault, the properties of the fault medium, water pressure and other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com