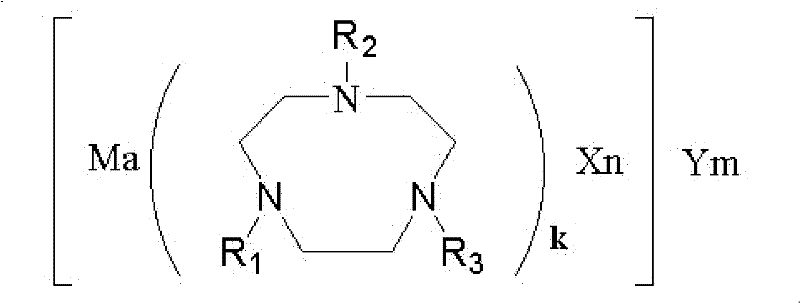

Method for activated bleaching by using 1,4,7-triazacyclononane complexes

A technology of triazacyclononane and metal complexes, applied in the field of low-temperature activation bleaching, which can solve the problems of immature application and shorten the stacking time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

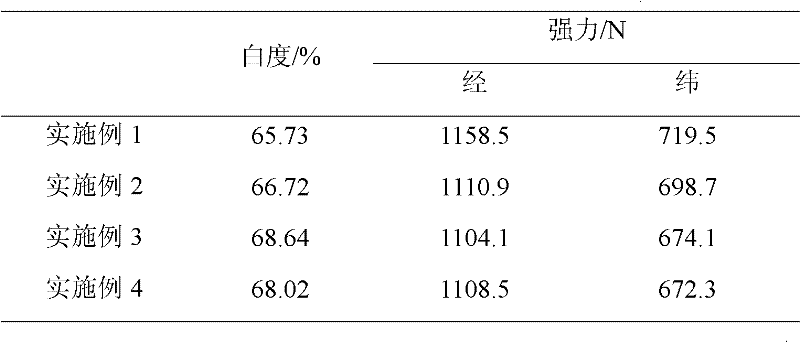

Embodiment 1

[0043] (1) Preparation of working solution: Add each additive in turn into a 1000ml container. Dosage of penetrant JFC: 2g / L; dosage of stabilizer MA-AA: 1g / L; activator Fe 2 -(1,4,7-Trimethyl-1,4,7-triazacyclononane)-Cl 2 Dosage: 3μmol / L; 30%H 2 o 2 Dosage: 30g / L; adjust the pH of the working solution to 8, stir evenly to treat the fabric.

[0044] (2) Padding treatment: the pure cotton semi-bleached cloth is soaked twice and rolled twice on a uniform padding machine with the working solution prepared in the above (1), and the liquid-carrying rate is 95%.

[0045] (3) Steaming step: the steaming temperature is 80° C., and the steaming time is 1 hour.

[0046] (4) Water washing: wash the steamed cotton fabric twice with hot water at 50° C. to 80° C., and then fully wash it with cold water.

Embodiment 2

[0048] (1) Preparation of working solution: Add each additive in turn into a 1000ml container. Dosage of penetrant JFC: 2g / L; dosage of stabilizer MA-AA: 1g / L; activator Fe 2-(1,4,7-Trimethyl-1,4,7-triazacyclononane)-Cl 2 Dosage: 15μmol / L; 30%H 2 o 2 Dosage: 30g / L; adjust the pH of the working solution to 9.5, stir evenly to treat the fabric.

[0049] (2) Padding treatment: the pure cotton semi-bleached cloth is soaked twice and rolled twice on a uniform padding machine with the working solution prepared in the above (1), and the liquid-carrying rate is 95%.

[0050] (3) Steaming step: the steaming temperature is 80° C., and the steaming time is 1 hour.

[0051] (4) Water washing: wash the steamed cotton fabric twice with hot water at 50° C. to 80° C., and then fully wash it with cold water.

Embodiment 3

[0053] (1) Preparation of working solution: Add each additive in turn into a 1000ml container. Penetrant JFC dosage: 2g / L; stabilizer MA-AA dosage: 0.5g / L; activator Fe 2 -(1,4,7-Trimethyl-1,4,7-triazacyclononane)-Cl 2 Dosage: 9μmol / L; 30%H 2 o 2 Dosage: 30g / L; adjust the pH of the working solution to 9, stir evenly to treat the fabric.

[0054] (2) Padding treatment: the pure cotton semi-bleached cloth is soaked twice and rolled twice on a uniform padding machine with the working solution prepared in the above (1), and the liquid-carrying rate is 95%.

[0055] (3) Steaming step: the steaming temperature is 80° C., and the steaming time is 1 hour.

[0056] (4) Water washing: wash the steamed cotton fabric twice with hot water at 50° C. to 80° C., and then fully wash it with cold water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com