X70QS seamless line pipe with HIC (Hydrogen Induced Cracking) resistance

A seamless line pipe, performance technology, applied in the field of corrosion-resistant materials and seamless pipes, can solve the problems of undefined steel grades and wide composition ranges, and achieve good HIC resistance, high strength, and low yield ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

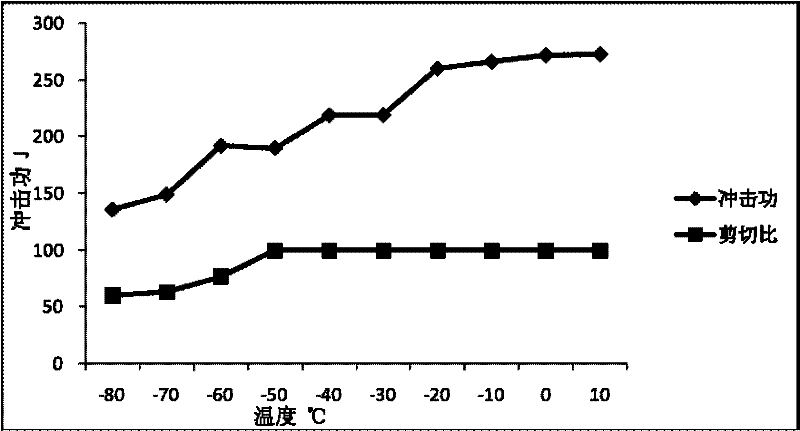

[0011] The X70QS seamless line pipe with anti-HIC performance of the present invention will be described with reference to the drawings and examples.

[0012] The X70QS seamless line pipe with HIC resistance performance of the present invention, the composition weight % of the seamless line pipe is C 0.06-0.14%, Si 0.20-0.45%, Mn 1.00-1.30%, P≤0.015%, S≤ 0.003%, Ni≤0.10%, Cu≤0.20%, Cr 0.05~0.30%, Mo0.05~0.30%, Al 0.015~0.060%, N 0.003~0.010%, Nb 0.030~0.050%, V0.05~0.09% , Ca≤0.060%, the balance is Fe and impurities; carbon equivalent CEpcm≤0.22%, CEIIW≤0.39%.

[0013] Cr and Mo in the composition are alloying elements and V and Nb are microalloying elements, and the addition amount is Cr+Mo≥0.15%, Cr+Mo+Mn≤1.80%, V+Nb≥0.09%.

[0014] It has good HIC resistance under yield strength ≥ 485MPa, crack sensitivity rate CSR ≤ 2%, crack length rate ≤ 10%, crack thickness rate CTR ≤ 3%.

[0015] The specific optimized chemical composition of the present invention is described as fol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com