Kitchen waste disposal method

A kind of technology of kitchen waste and treatment method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

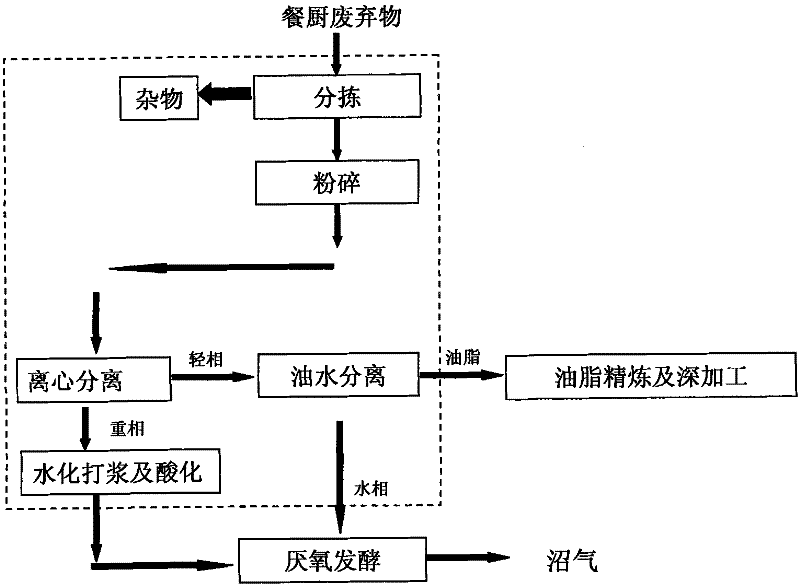

[0019] As shown in Figure 1, the processing method of this kitchen waste comprises the following processing steps:

[0020] ①Sorting and removing impurities: Sorting the collected kitchen waste, that is, kitchen waste, to remove metal, plastic, glass bottles and other sundries to obtain biodegradable kitchen waste; the sorted sundries are useful and can be Recycling, useless landfill. According to the specific conditions of the collected food waste, secondary sorting can be carried out if necessary.

[0021] ② Crushing: In this embodiment, the biodegradable kitchen waste obtained after sorting is crushed by the fluid cutting method. The fluid processing method drives the fluid cutting machine through a hydraulic motor or a gear motor, with a speed of 60-400rpm and a processing flow of 10-100m 3 / h. A mixture with particle diameter ≤ 8mm is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com