Technology for preparing cobalt hydroxide from cobaltous sulfate solution

A technology of cobalt sulfate solution and cobalt hydroxide, which is applied in the direction of cobalt oxide/cobalt hydroxide, can solve the problems of non-return, cobalt content reduction, and poor filtration performance of precipitated products, so as to improve the reaction speed, increase the particle size, and effectively good for filtering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

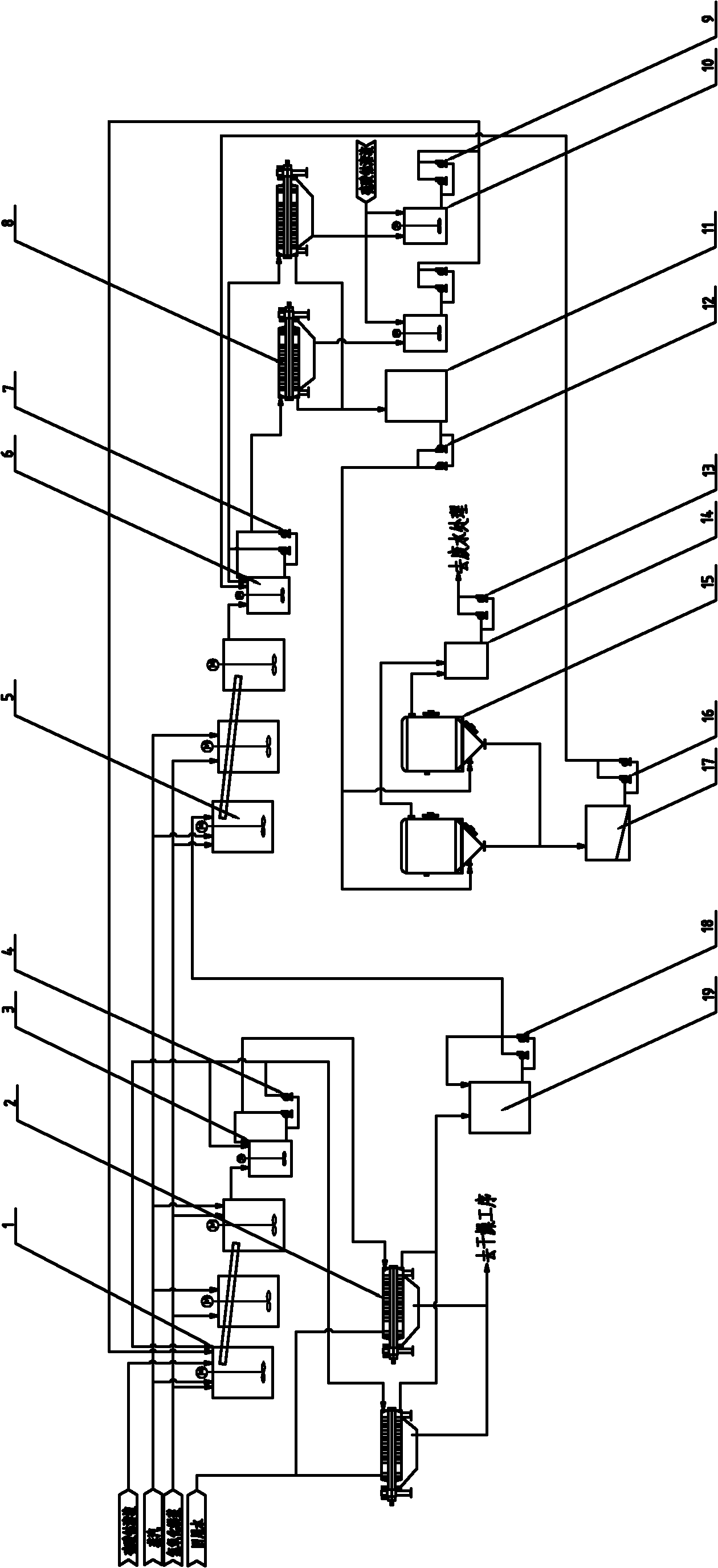

[0016] Such as figure 1 As shown, the cobalt sulfate solution is pumped into the primary cobalt precipitation tank 1, and at the same time, the magnesium hydroxide slurry with a mass percentage of 25% is pumped in, and the addition amount is controlled so that the pH value is stable at about 7.5, and steam is introduced into the jacket Control the reaction temperature at about 60°C, the primary cobalt precipitation slurry flows into the primary cobalt precipitation buffer tank 3, and a part (30-50%) of the slurry is returned to the primary cobalt precipitation tank 1 as the seed crystal for subsequent reactions; The other part is sent to the primary cobalt precipitation filter press 2 by the primary cobalt precipitation slurry delivery pump 4 for pressure filtration, the obtained filter cake is sent to the drying process, and the filtrate enters the primary cobalt precipitation liquid storage tank 19, and passes through the primary cobalt precipitation filtrate. The delivery p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com