Scrap metal briquetting machine

A briquetting machine and scrap metal technology, applied in the direction of presses, manufacturing tools, etc., can solve the problems of small pre-pressure, complex flip structure, unsuitable for continuous production, etc., achieve high compression force, good reliability, and reasonable compression method Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific embodiments of the present invention will be described below in conjunction with the drawings.

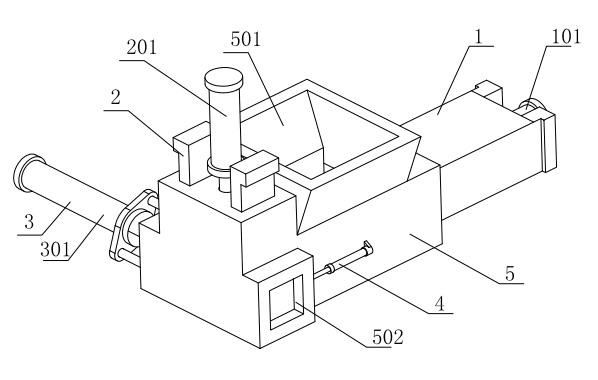

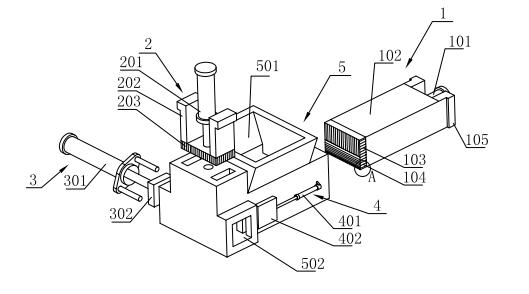

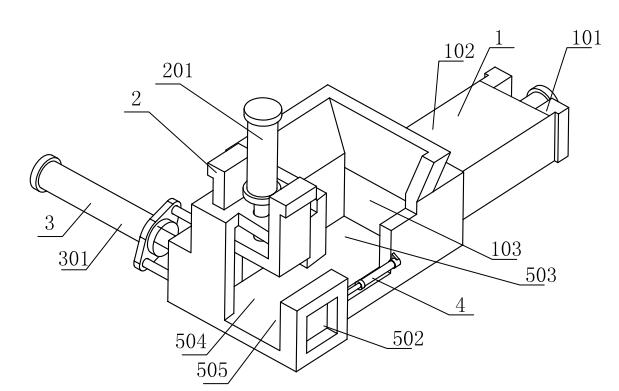

[0019] Such as figure 1 , figure 2 As shown, the scrap metal briquetting machine of the present invention is composed of a fuselage 5 and a three-way hydraulic device, including a horizontal hydraulic device 1, a vertical hydraulic device 2, and a longitudinal hydraulic device 3. The metal scrap is compressed in three directions, and finally Forms bulk metal. Such as figure 2 As shown, the top of the fuselage 5 is provided with a metal scrap entrance hopper silo 501, a metal block exit 502 is provided in the front of the lower part, and a baffle door 402 is provided at the exit 502. It is controlled by a horizontally arranged door opening hydraulic assembly 401. Sliding in the direction to realize the opening and closing of the baffle door 402. The inside of the fuselage 5 is a complete cavity, which can be divided into a pre-extrusion cavity 503, a secondary ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com