Laser cutting device with workpiece bottom immersed in liquid level

A technology of laser cutting and immersion liquid, which is applied in the direction of glass cutting devices, laser welding equipment, manufacturing tools, etc., can solve the problems of different loss, interference power, reduction, etc., and achieve good cooling effect and good cutting quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

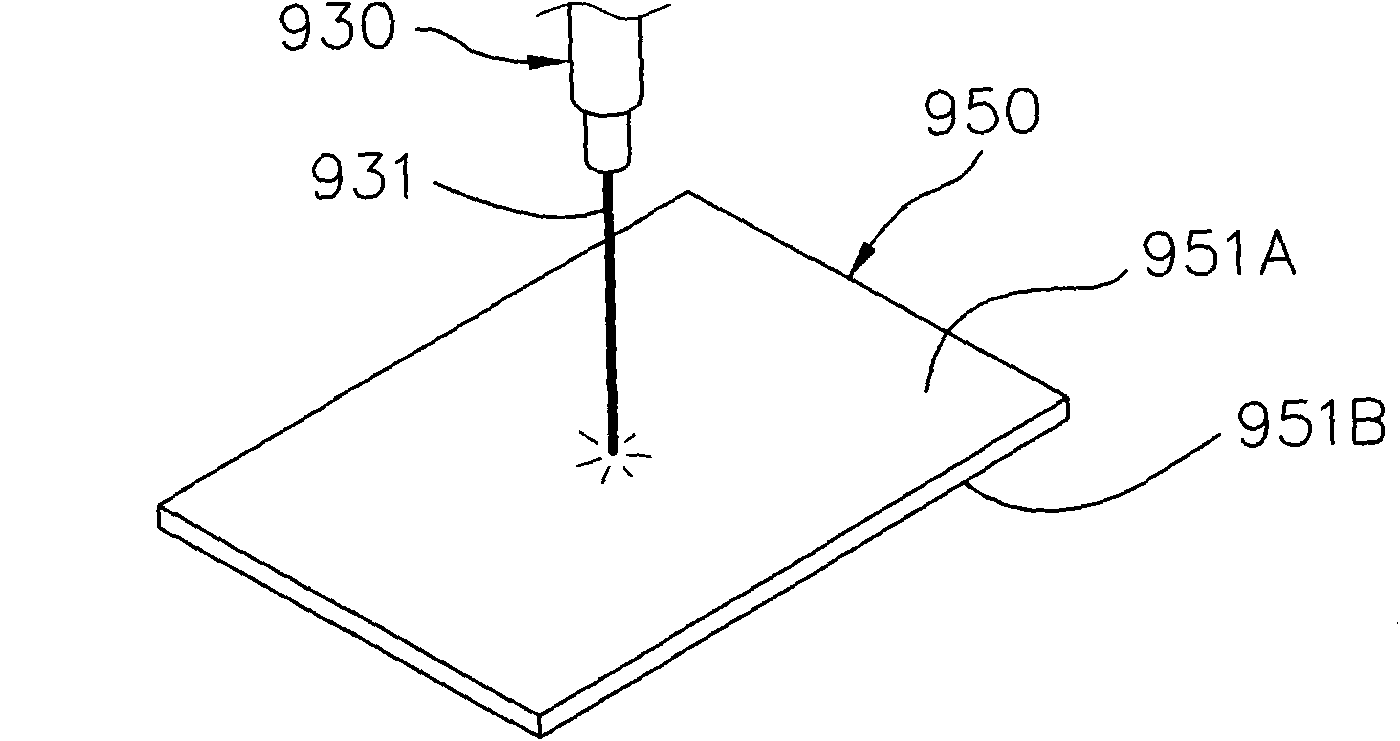

[0048] Such as image 3 And shown in Fig. 4, a kind of laser cutting device that the bottom surface of the workpiece of the present invention is immersed in liquid surface, it comprises:

[0049] A liquid container 10 for containing a liquid 70 (for example: water);

[0050] A workpiece fixing portion 20, used to fix a workpiece 50, the workpiece 50 has a first surface 51 and a second surface 52, the first surface 51 of the workpiece 50 is immersed in the liquid 70;

[0051] A laser generator 30 is used to generate a laser beam 31 onto the second surface 52 of the workpiece 50 to cut the workpiece 50 .

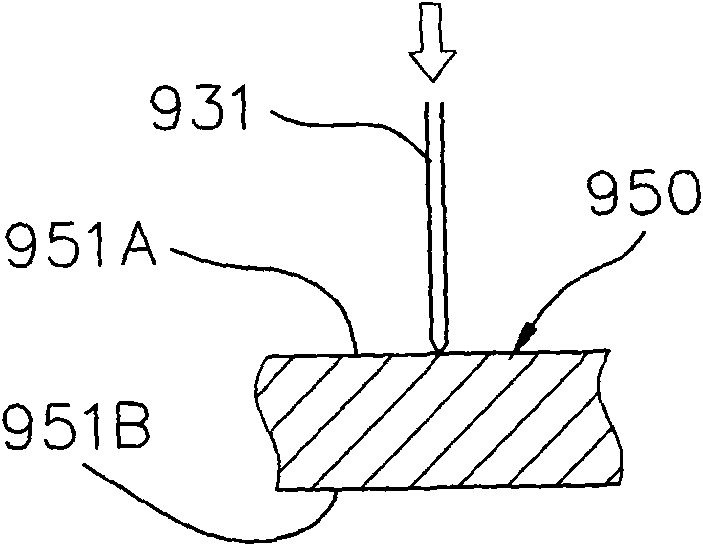

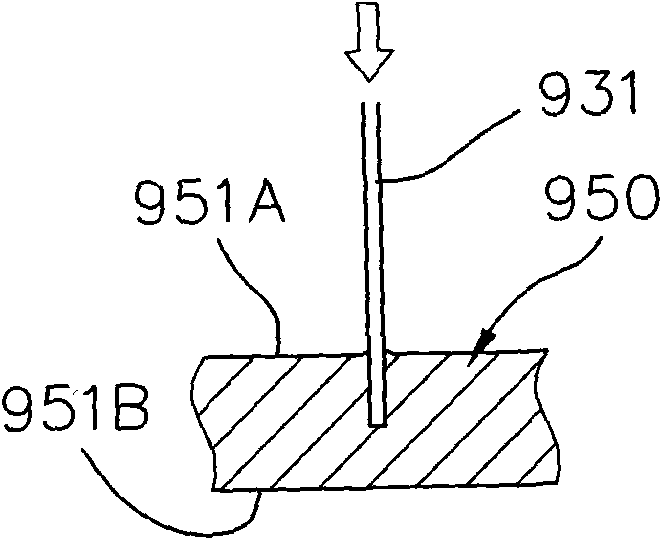

[0052] Such as Figure 4A and Figure 4B As shown, when the laser beam 31 cuts the workpiece 50, it penetrates from the second surface 52 of the workpiece 50 to the first surface 51 to form a cutting wall 53; Figure 4C As shown, at the moment when the cutting wall 53 penetrates, the liquid 70 below the first surface 51 will rush into the cutting wall 53 due to the concent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com