Transformer temperature controller with external heating elements

A technology for heating elements and transformers, which is applied to transformer/inductor parts, electrical components, and temperature control by electric means, which can solve the changes affecting the displacement of the push rod, the accuracy of detection, the stiffness of the push rod and the hard force. and other problems to achieve the effect of avoiding local overheating, simple structure and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

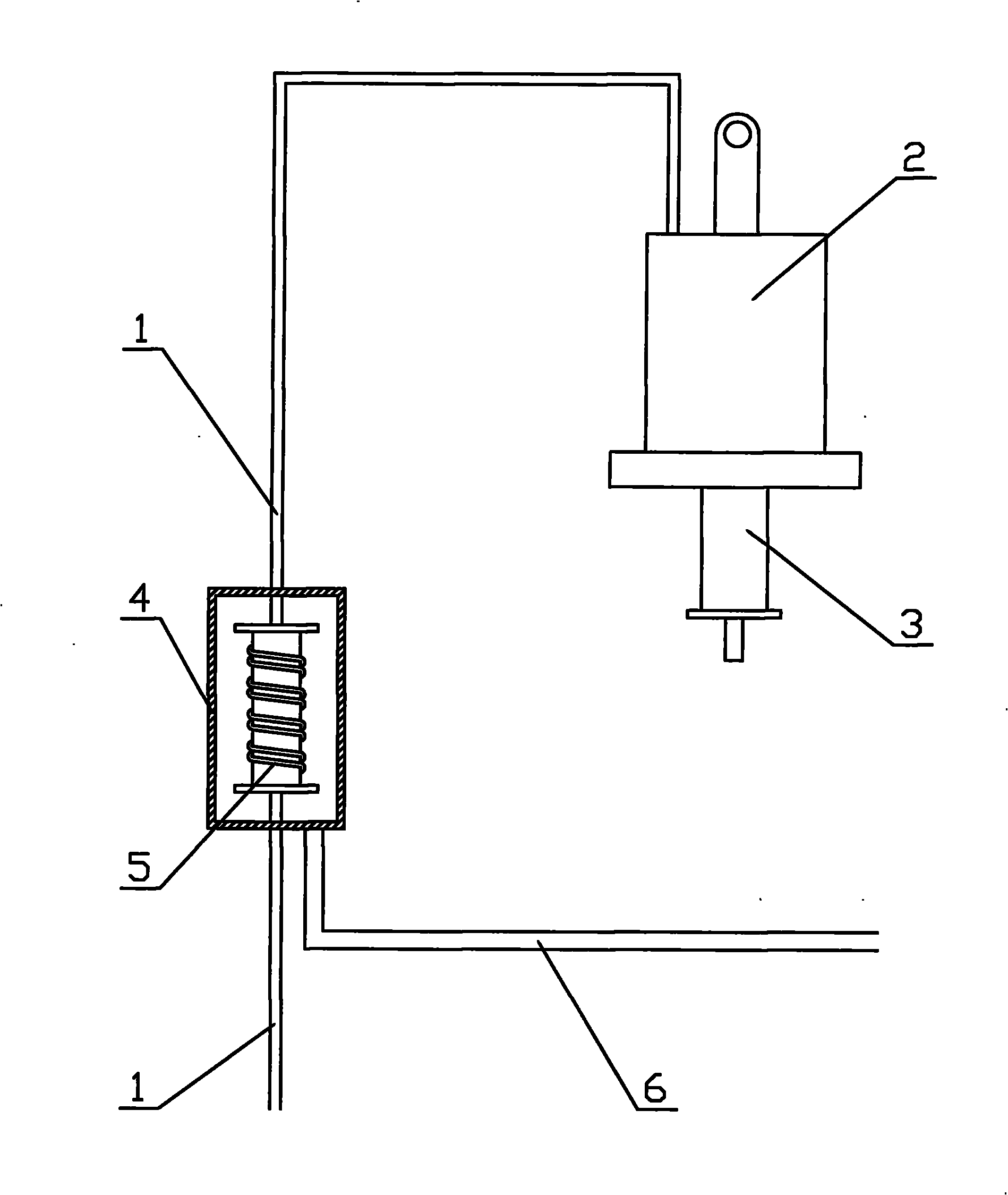

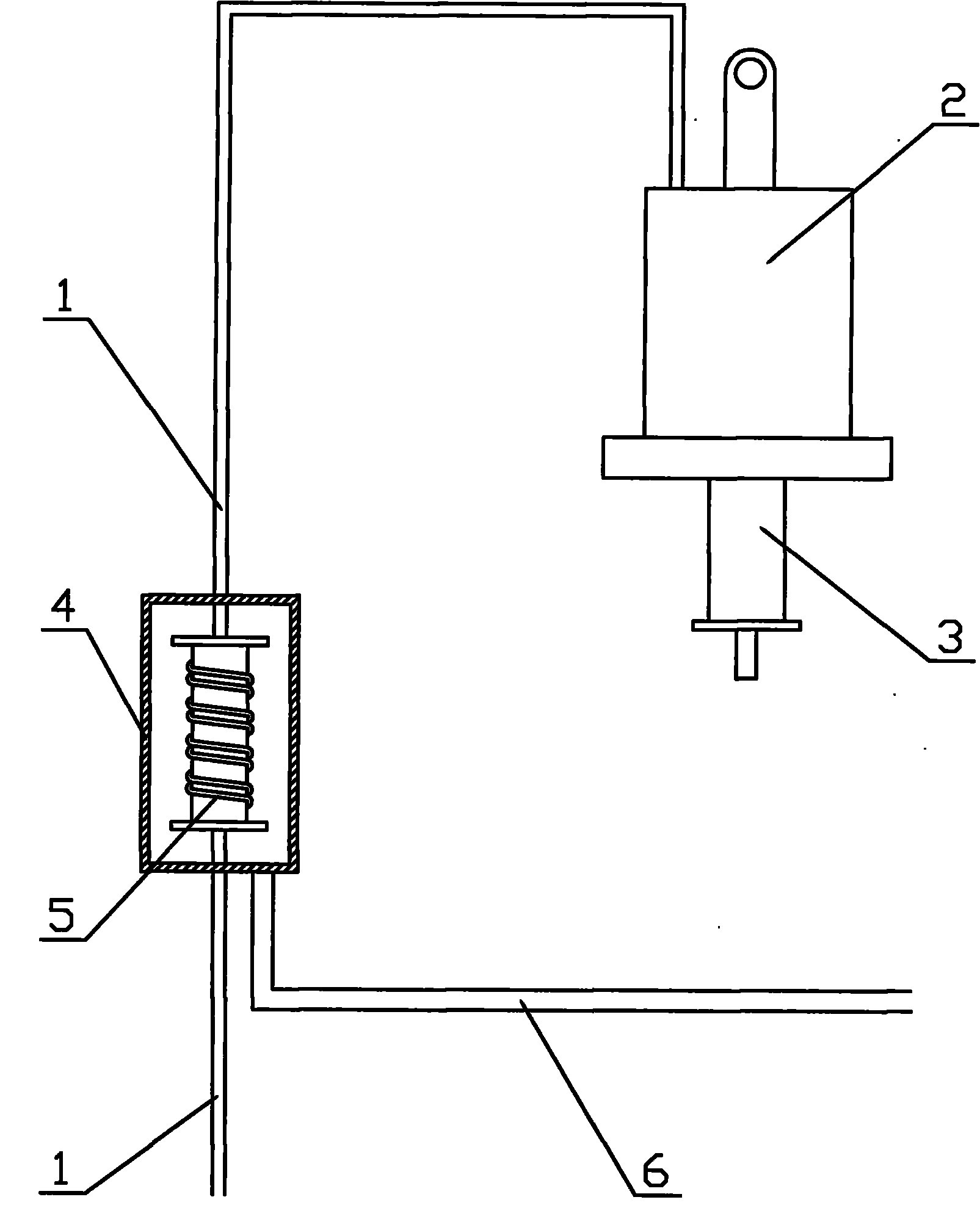

[0007] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as figure 1 Shown: Same as the prior art, there is a sensing conduit 1 and a copper body 2 connected to the sensing conduit 1, a push rod 3 is arranged at the other end of the copper body 2, and a push rod 3 is arranged at the middle part of the sensing conduit 1. A heating pipe body 4 with high temperature resistance, such as a copper pipe, is connected in series, and an electric heating element 5, such as a resistance wire, is arranged outside the heating pipe 4 or built in. connect.

[0008] work process:

[0009] The current of the transformer winding is output by the converter to the electric heating element 5 through the wire, and the electric heating element 5 heats the temperature-sensing medium in the heating tube body 4, and the volume of the temperature-sensing medium changes with the heating current. The push rod 3 produces...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com