Digital full functional water nozzle test system

A test system and water nozzle technology, applied in the field of test benches, can solve the problems of inability to output data, accurate inspection, inability to accurately control and accurately know the flow rate of nozzles, etc., and achieve economical and convenient effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below according to the embodiments and the accompanying drawings.

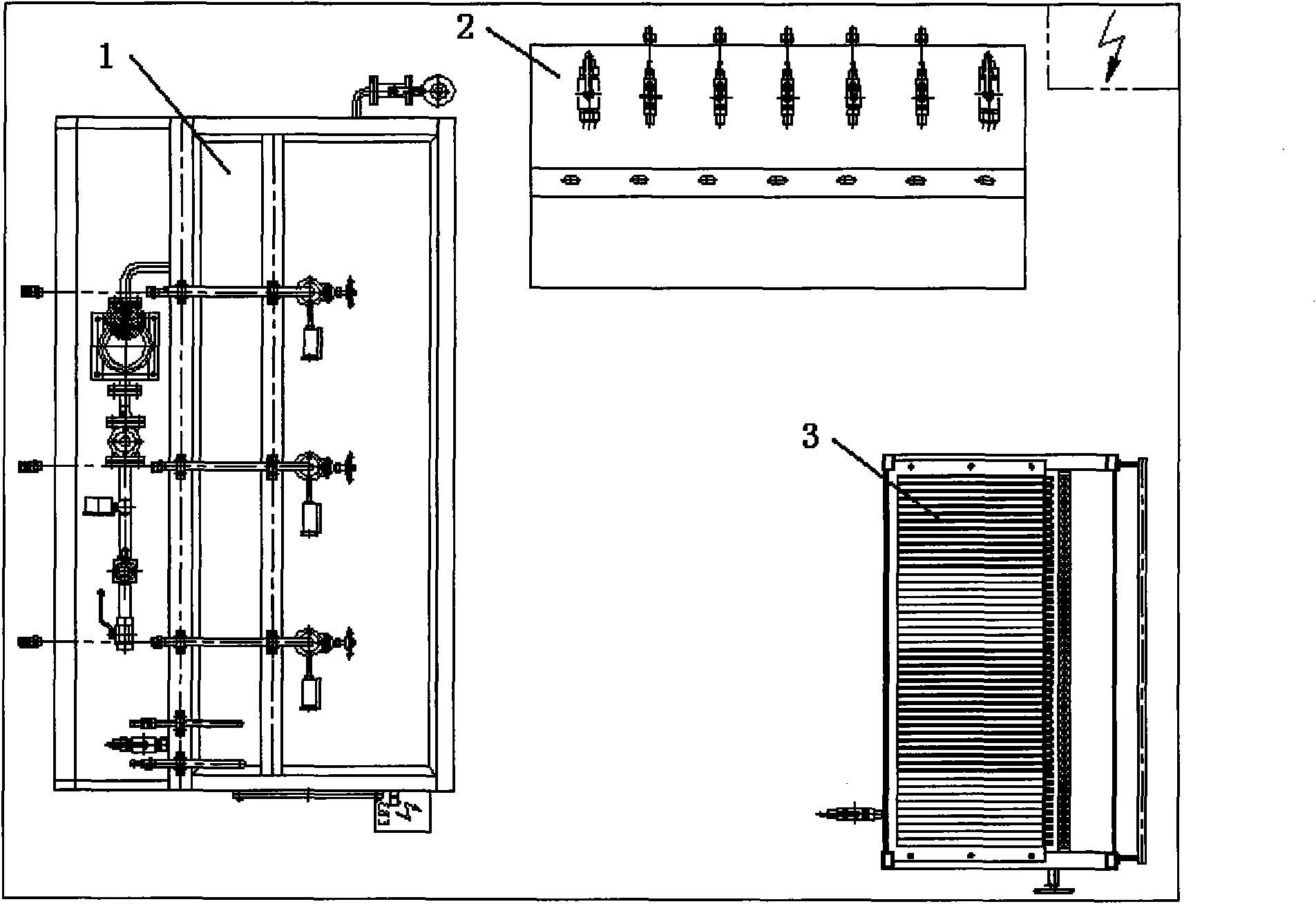

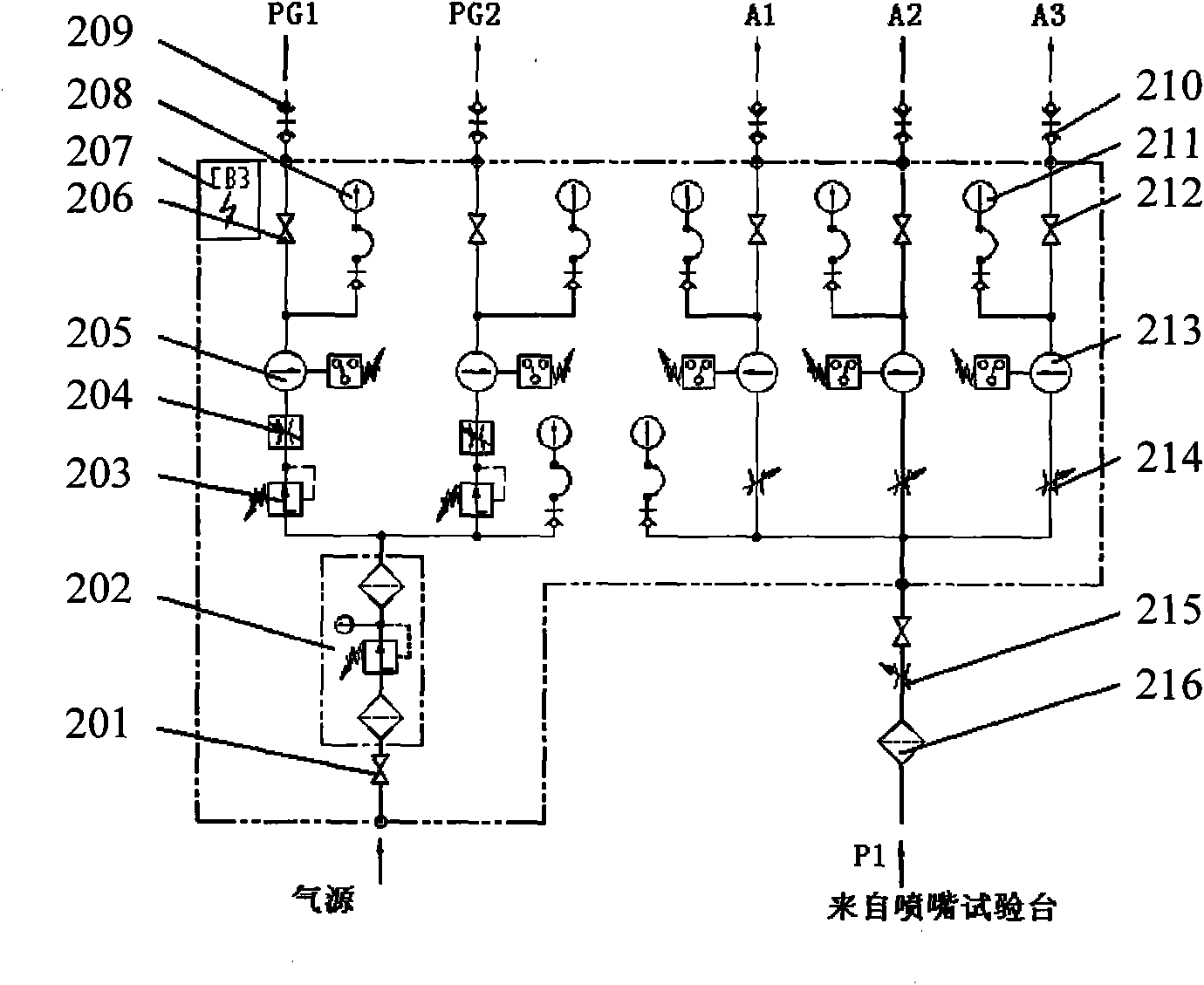

[0022] like figure 1 As shown, the digital full-function water nozzle test system includes a cycle energy station 1 that provides power for the test, a water and gas console 2 for realizing water and gas distribution, throttling, and metering, and a field simulation nozzle water distribution test bench 3, three The parts are independent and connected in turn through the pipeline interface. All the measuring instruments adopt digital intelligent instruments, and the corresponding data collected can be input into the computer for processing; the structure of the flow distributor of the field simulation nozzle water distribution test bench is a parallel deflector partition A groove with the same width is formed, and a transparent glass container is used as a metering device below.

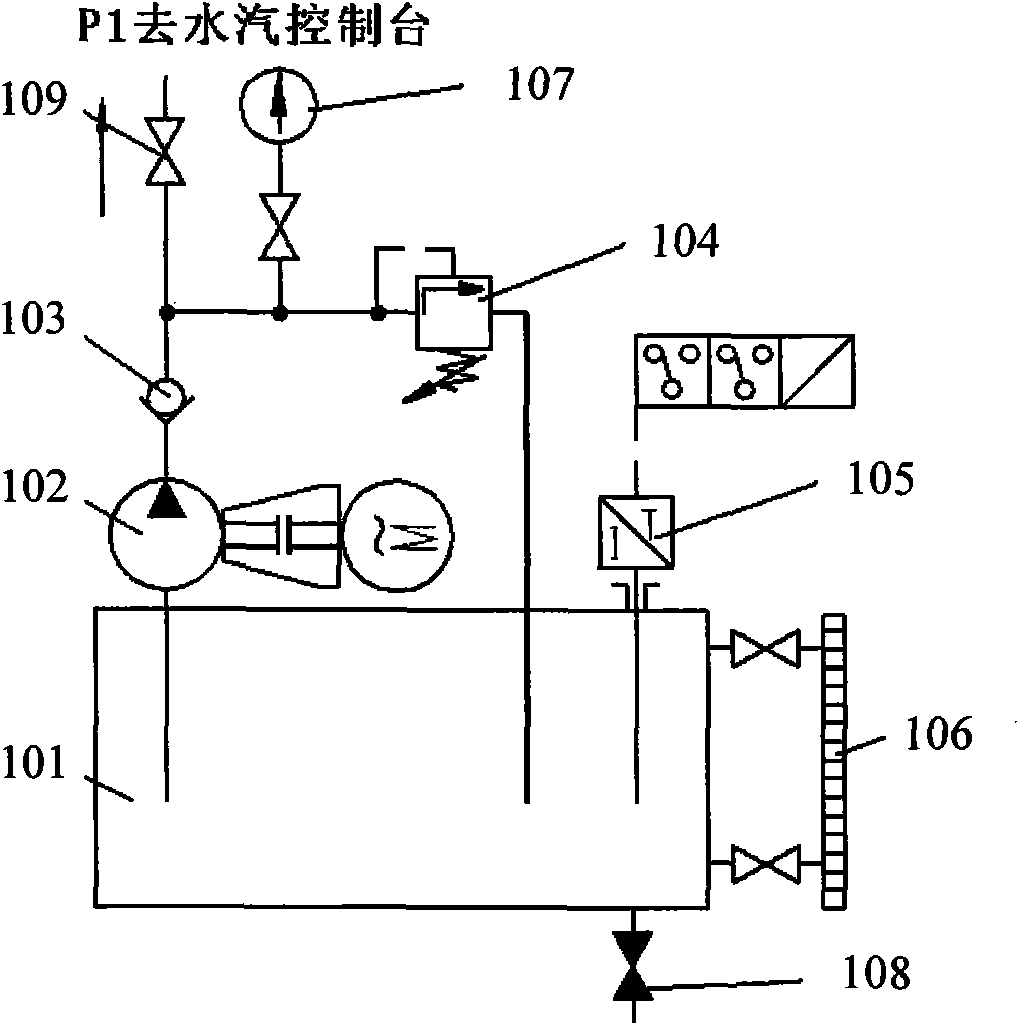

[0023] like figure 2 As shown, the test bench cycle energy stati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com