Device for measuring straightness/coaxiality by applying laser

A technology of coaxiality measurement and straightness, which is applied in the direction of measuring devices, optical devices, instruments, etc., can solve the problems of cumbersome adjustment process, inability to ensure coincidence, heavy workload, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be described below in conjunction with the accompanying drawings.

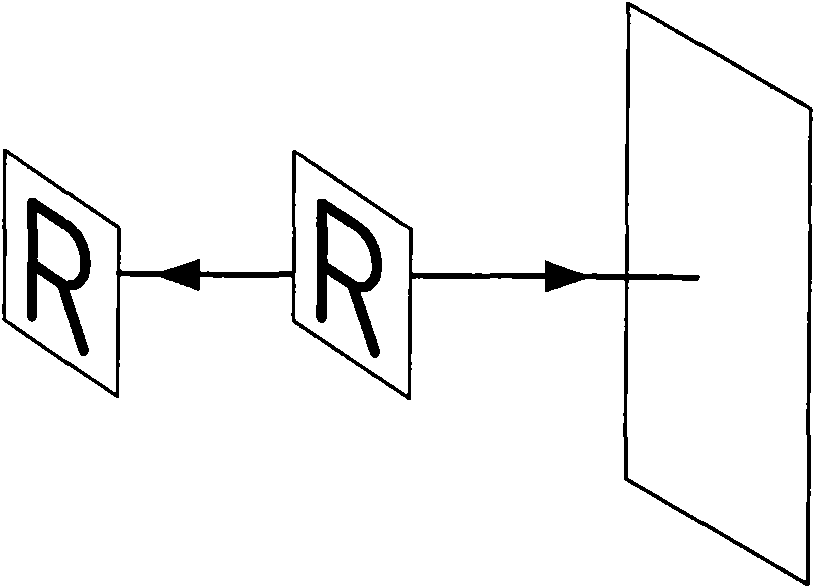

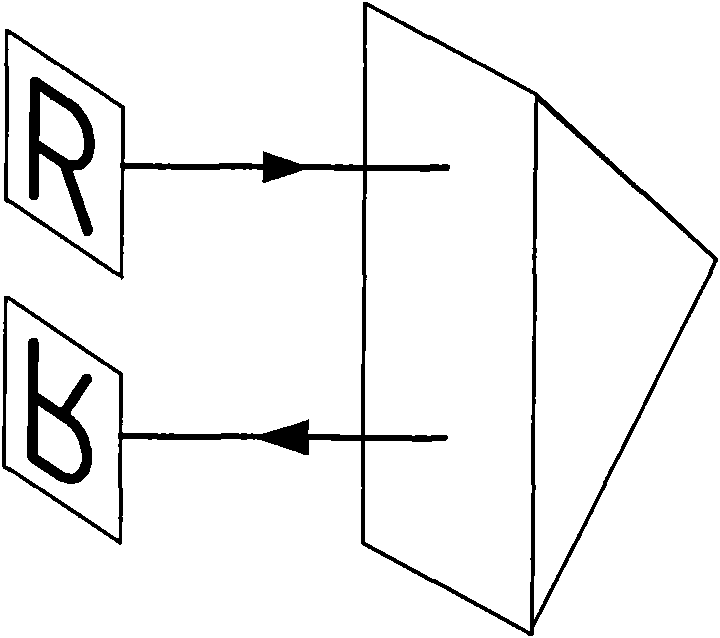

[0045] image 3 It is a schematic structural diagram of the preferred laser straightness / coaxiality measuring device of the present invention. Comprising horizontal Zeeman dual-frequency laser light source 201, telescope 202, beam splitter 203, movable sleeve 206 that can rotate 90 degrees, first Wollaston prism 207, second Wollaston prism 208 and translation reflector 209, the second Wollaston prism 208, the first Wollaston prism 207 and movable sleeve 206 are positioned at the optical path of returning light after reflecting from translation reflector 209 successively, in On the optical path of the returned light, after the movable sleeve 206, a second analyzer 210 and a second photoelectric receiver 211 are sequentially arranged to receive the returned light. 204 and the first photoelectric receiver 205, and a signal processing unit composed of a signal amplifying circuit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com